Vacuum thermal insulation material and core material

A vacuum insulation material and core material technology, which is applied in heat exchange equipment, pipeline protection through heat insulation, heat preservation, etc., can solve unsolved core material and other problems, achieve easy control of the amount of glue added, reduce operation difficulty, and ensure smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

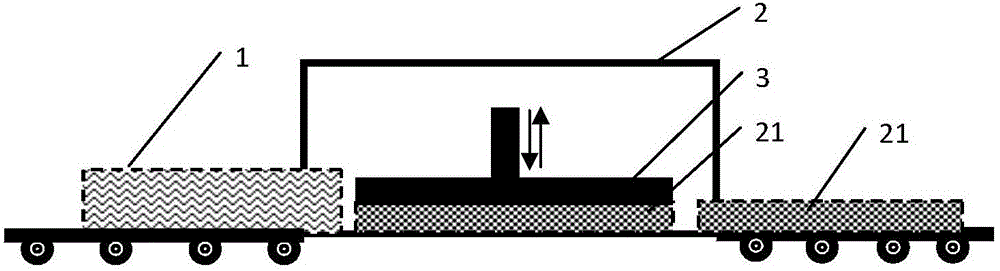

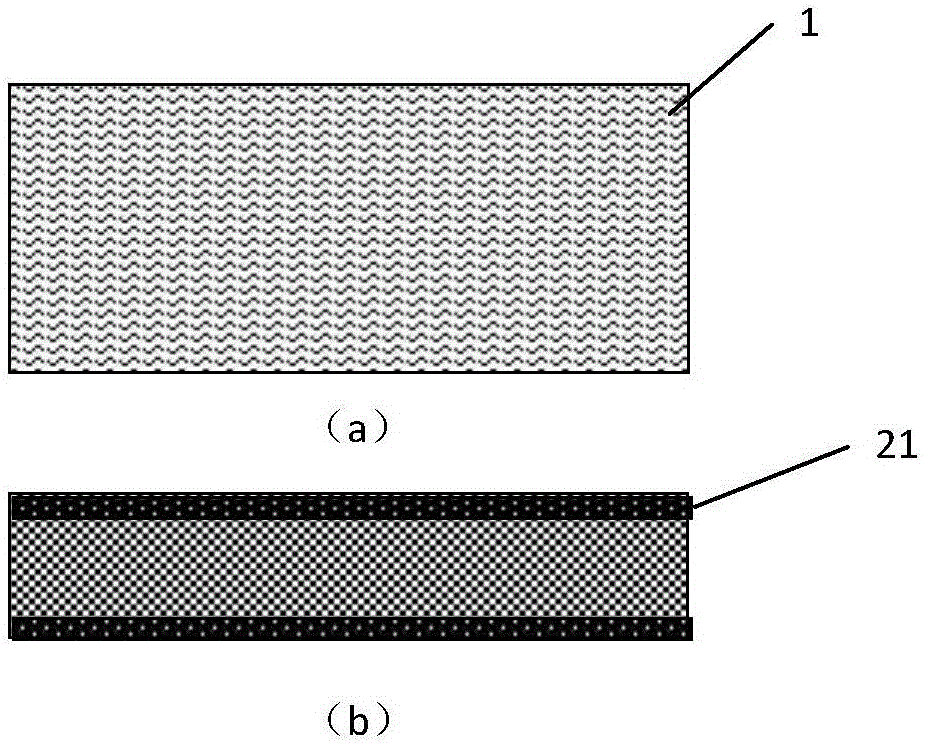

[0025] The core material 1 is glass fiber, and the core material 1 is heated and pressurized at a constant temperature by the press 3 and the high-temperature box 2, and the pressure is along the thickness direction of the glass wool felt, wherein the pressure is 0.7-0.9 atmospheres, and the heating and pressing time is 12min. The heating temperature is set at 0°C-18°C above the thermoplastic deformation temperature of the core material, preferably the thermoplastic deformation temperature of the core material is 500°C, and the heating temperature is 518°C. After the core material is heated and pressed, the fibers on the surface undergo plastic deformation, accompanied by fiber breakage and pulverization. The core material is sequentially cut, dried, and packaged under reduced pressure, and the surface flatness deviation of the prepared vacuum heat insulation material is 2 mm.

Embodiment 2

[0027] The core material 1 is glass fiber, and the core material 1 is heated and pressurized at a constant temperature by the press 3 and the high-temperature box 2, and the pressure is along the thickness direction of the glass wool felt, wherein the pressure is 0.2-0.5 atmospheres, and the heating and pressing time is 10min. The heating temperature is set at 50°C-80°C above the thermoplastic deformation temperature of the core material, preferably the thermoplastic deformation temperature of the core material is 500°C, and the heating temperature is 580°C. Fracture and pulverization occur. The core material is sequentially cut, dried, and packaged under reduced pressure, and the surface flatness deviation of the prepared vacuum heat insulation material is 2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com