Anti-explosion LED module

A technology of LED modules and LED light strips, which is applied in the direction of gas-proof/waterproof devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc. Poor explosion-proof performance and other problems, to achieve the effect of high electro-optic conversion efficiency, perfect safety protection, and improve explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

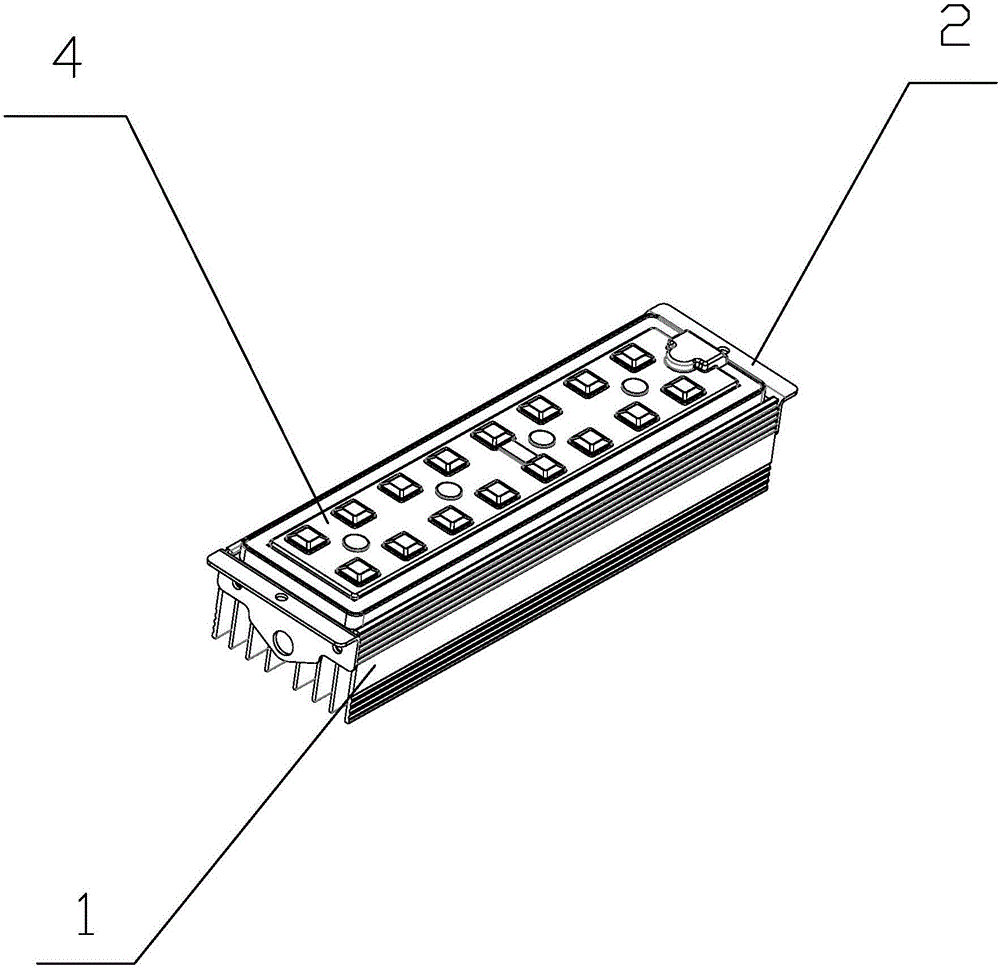

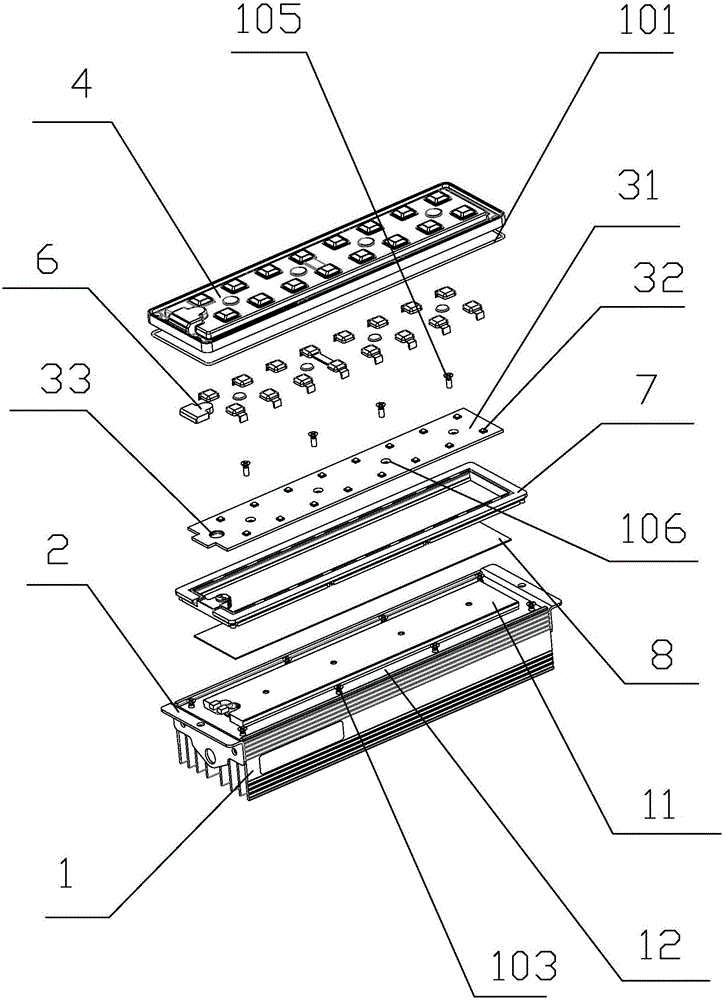

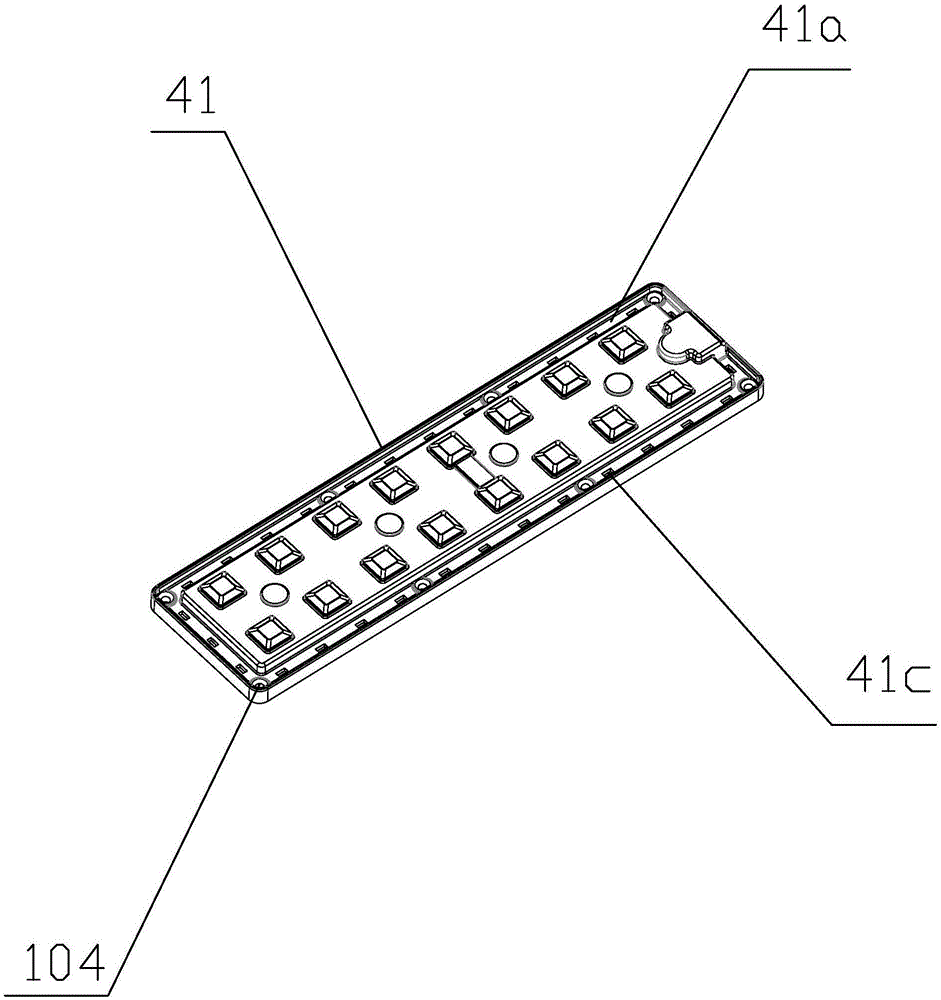

[0037] Embodiments of the explosion-proof LED module of the present invention are Figures 1 to 11 As shown: it includes a lamp body, a light-emitting assembly fixed on the lamp body and a fixture fixed to the lamp body. The light-emitting assembly includes a light-emitting part and a lampshade 4 that covers the light-emitting part. The cable assembly 9 connected with it is formed. The LED light strip 3 includes a substrate 31 and LED particles 32 distributed on the substrate 31. The lamp body includes a heat sink 1, and the heat sink 1 includes a 3 heat dissipation table 11 and the installation groove 12 surrounding the heat dissipation table 11, the lampshade 4 is inserted into the installation groove 12 around the heat dissipation table 11, and there is a space between the lampshade 4 and the LED light strip 3 for accommodating LED particles 32 The light source chamber 41, the light source chamber 51 is poured with transparent organic silica gel 6 that makes the LED particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com