Wind speed sensing device based on fiber bragg gratings, and wind direction monitoring system

A fiber grating, wind speed sensing technology, applied in the direction of speed/acceleration/shock measurement, measurement device, fluid speed measurement, etc., can solve the problems of complicated wind speed sensor device, interference, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

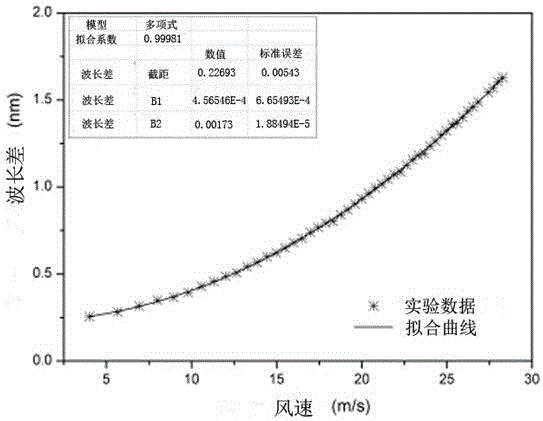

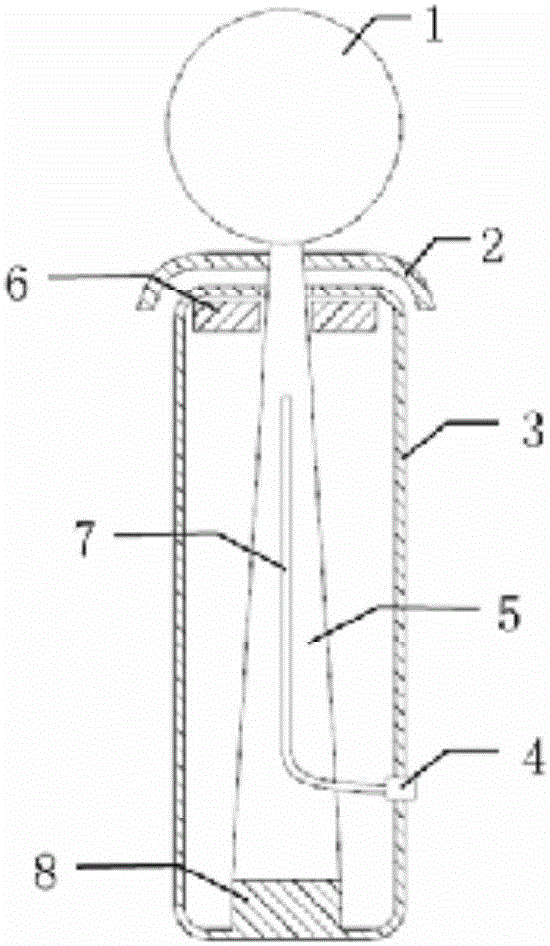

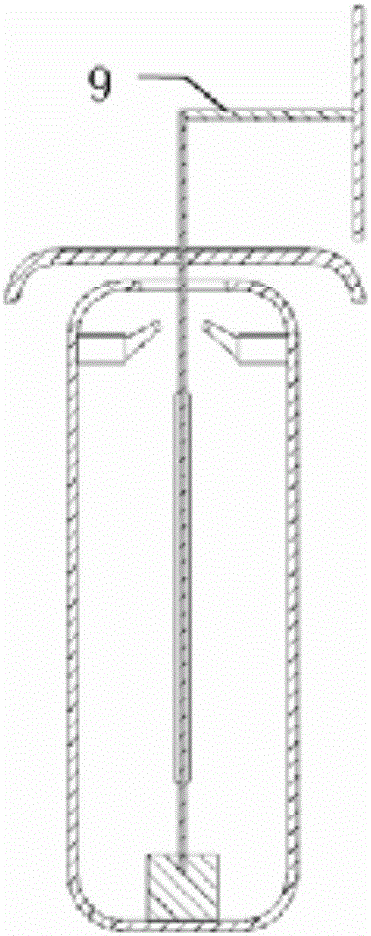

[0033] The present invention relates to a schematic structural diagram of a wind speed sensing device based on a fiber grating such as figure 1 with figure 2 shown. The wind speed sensing device includes: a circular windward pressure plate 1 , a cantilever beam of equal strength 5 , a dust cover 2 , an optical fiber grating 7 , an optical fiber adapter 4 , a self-heating device 6 and a packaging shell 3 . The windward pressure plate 1 is welded to the top of the equal-strength cantilever beam 5 through the connecting rod 9; the equal-strength cantilever beam 5 is fixed on the base of the packaging shell 3, and an optical fiber Bragg grating is welded on the central axis of the front and back surfaces of the beam, respectively. Located in the 850nm wavelength band, in order to ensure that the fiber grating is evenly stressed, the equal-intensity beam 5 is designed in the shape of an isosceles triangle within the effective force-bearing range. The grating pigtail passes throu...

Embodiment 2

[0045] Figure 5 It is an example diagram of the wind speed and wind direction monitoring system proposed based on the wind speed sensing device, including two above-mentioned fiber grating wind speed sensors, optical fiber jumpers, wavelength demodulation equipment and remote control computer four parts. Two fiber grating wind speed sensors are placed orthogonally to measure the projected components of the wind speed in two vertical directions, and finally the wind direction information can be obtained through geometric synthesis calculation. The detection signals of the two sensors are sent to the remote wavelength demodulation device through the optical fiber jumper. In order to reduce the cost and simplify the system in the present invention, the wavelength information of the fiber Bragg grating is converted into the optical signal intensity for demodulation, and then the wind speed and direction information is calculated according to the corresponding model. Finally, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com