Electric automobile power battery major loop circuit relay failure detection circuit and method

A technology for relay faults and power batteries, applied in electric vehicles, circuit breaker testing, battery/fuel cell control devices, etc., can solve problems such as failure to find fault prompts, and achieve convenient vehicle layout, simple wiring, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

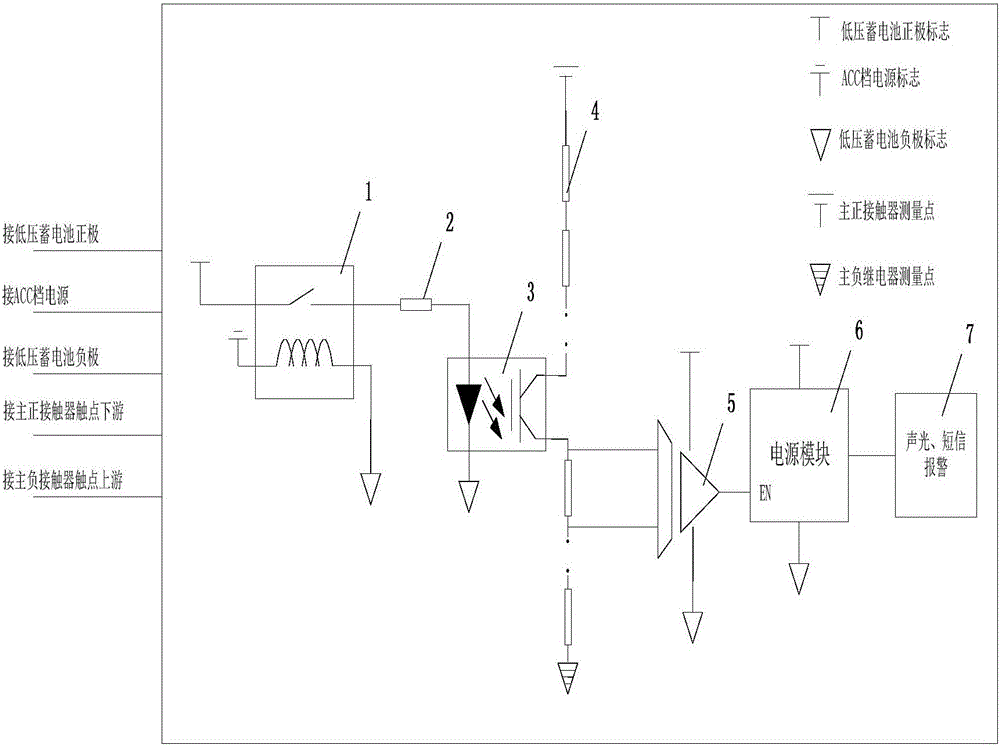

[0038] The schematic diagram of the fault detection circuit is as follows: figure 1 As shown, the interface with the vehicle includes: the positive pole of the low-voltage battery, the ON gear power supply, the negative pole of the low-voltage battery, the downstream of the main positive relay contact of the power battery, and the upstream of the main negative contactor contact of the power battery. The detection circuit includes: a normally closed low-voltage relay 1, a current-limiting resistor 2, a high-voltage optocoupler 3, a voltage dividing resistor 4, an isolation amplifier 5, a power supply module 6, and an audible-light and SMS alarm module 7. One end of the normally closed low-voltage relay contact is connected to the positive pole of the low-voltage battery, one end is connected to the high-voltage optocoupler control terminal through a current-limiting resistor, one end of the low-voltage relay coil is connected to the ACC power supply, and the other end is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com