Power distribution cabinet structure

A technology for power distribution cabinets and cabinets, applied in substation/power distribution device shells, electrical components, substation/switch layout details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

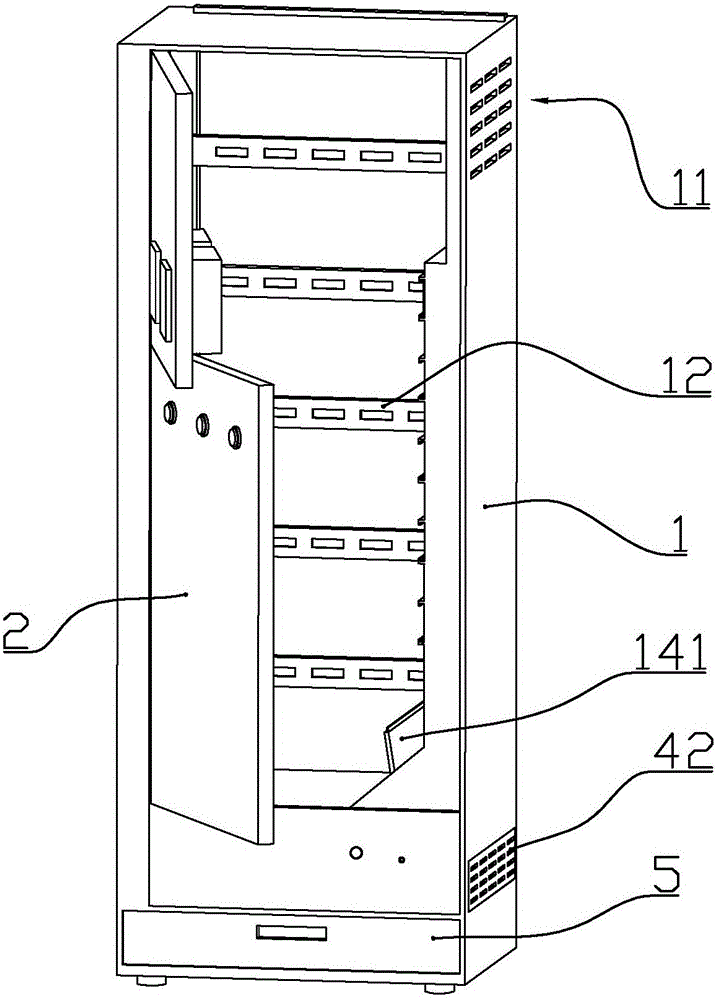

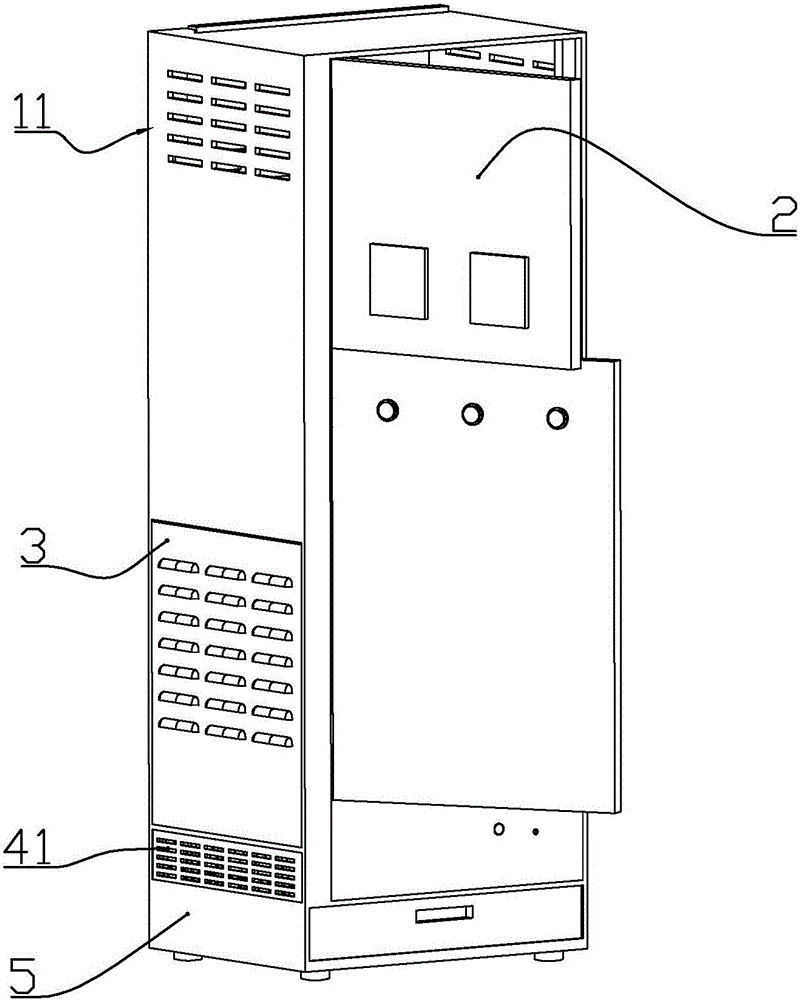

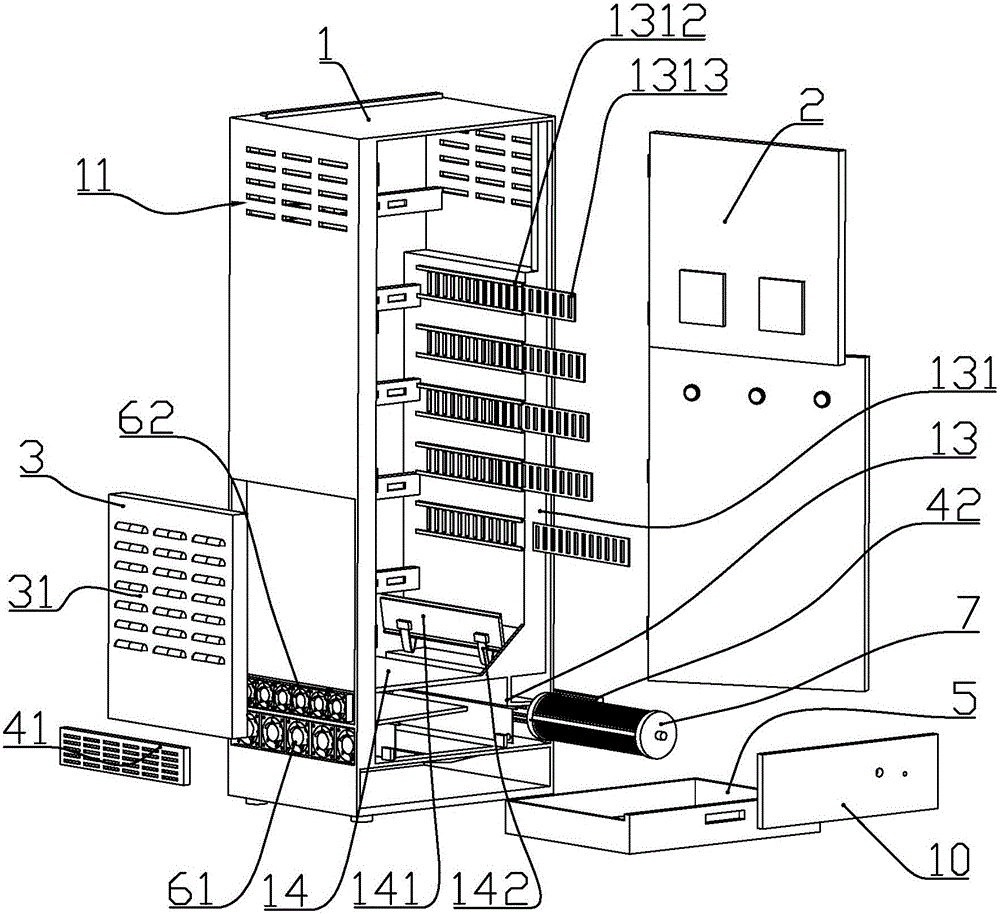

[0066] according to Figure 1 to Figure 13 As shown, this embodiment is a power distribution cabinet structure, including a cabinet body 1 with an open front end, and a cabinet door 2 connected to the front end of the cabinet body through hinges; multiple sets of horizontally arranged cabinets are installed at the rear of the cabinet body. Mounting frames 12; the mounting frames are arranged equidistantly along the vertical direction; air outlets 11 are formed on the left and right sides of the upper part of the cabinet.

[0067] The bottom of the cabinet body is formed with a slope plate 16 that is high on both sides and low in the middle; in the cabinet, the rear side of the cabinet is the rear cabinet, and the bottom of the rear cabinet is located above the middle of the slope. A stepper motor 8 is installed. The output shaft of the stepping motor is connected with a cooling plate assembly 7 arranged horizontally along the front and back direction of the cabinet.

[0068] ...

Embodiment 2

[0083] according to Figure 1 to Figure 13 As shown, this embodiment is a power distribution cabinet structure, including a cabinet body 1 with an open front end, and a cabinet door 2 connected to the front end of the cabinet body through hinges; multiple sets of horizontally arranged cabinets are installed at the rear of the cabinet body. Mounting frames 12; the mounting frames are arranged equidistantly along the vertical direction; air outlets 11 are formed on the left and right sides of the upper part of the cabinet.

[0084] The bottom of the cabinet body is formed with a slope plate 16 that is high on both sides and low in the middle; in the cabinet, the rear side of the cabinet is the rear cabinet, and the bottom of the rear cabinet is located above the middle of the slope. A stepper motor 8 is installed. The output shaft of the stepping motor is connected with a cooling plate assembly 7 arranged horizontally along the front and back direction of the cabinet.

[0085] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com