Electric heater for preheating and solidification prevention of high-temperature molten salt conveying pipe

A technology for transmission pipelines and high-temperature molten salt, applied in the shape of heating elements, electrical components, electric heating devices, etc., can solve the problems of insufficient molten salt preheating and anti-solidification, achieve short heating time, high working temperature, and prevent broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

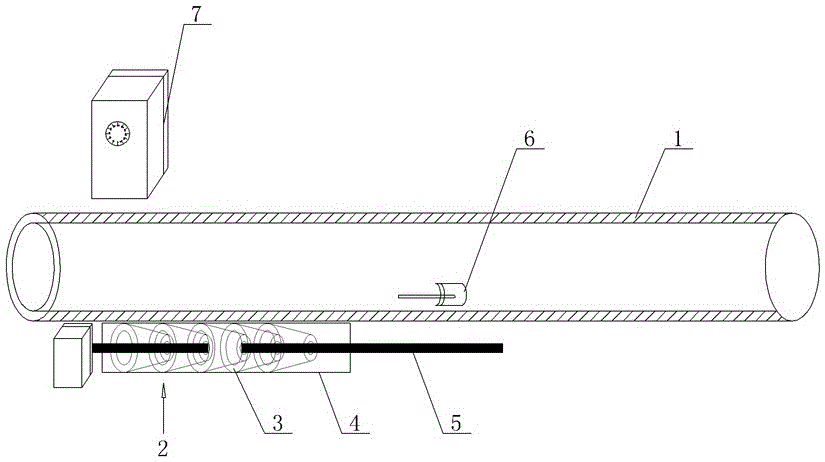

[0015] The preheating and anti-freezing electric heater of the high-temperature molten salt transmission pipeline of the present embodiment, such as figure 1 As shown, it includes an electric heating tube 2 wound on the outer wall of the high temperature molten salt transmission pipeline 1 or an electric heating tube 2 laid in parallel along the high temperature molten salt transmission pipeline 1 and close to the bottom of the high temperature molten salt transmission pipeline.

[0016] The electric heating tube 2 is made of a high-temperature nickel-chromium alloy resistance wire 5 passing through a plurality of insulating fixtures 3 in sequence and covered with a high-temperature fiber sheath 4 . The insulating fixture 3 usually adopts ceramic beads. The electric heating tube 2 is pasted on the high-temperature molten salt transmission pipeline 1 by heat-resistant aluminum tape at intervals of 0.5-0.8 m.

[0017] In this embodiment, a temperature sensor 6 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com