Photoconductive diamond film switch

A photoconductive switch, diamond film technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of narrow wavelength range of excitation laser, limited application of photoconductive switch, insufficient voltage resistance, etc., to improve heat dissipation performance and fast response speed. , the effect of improving the pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

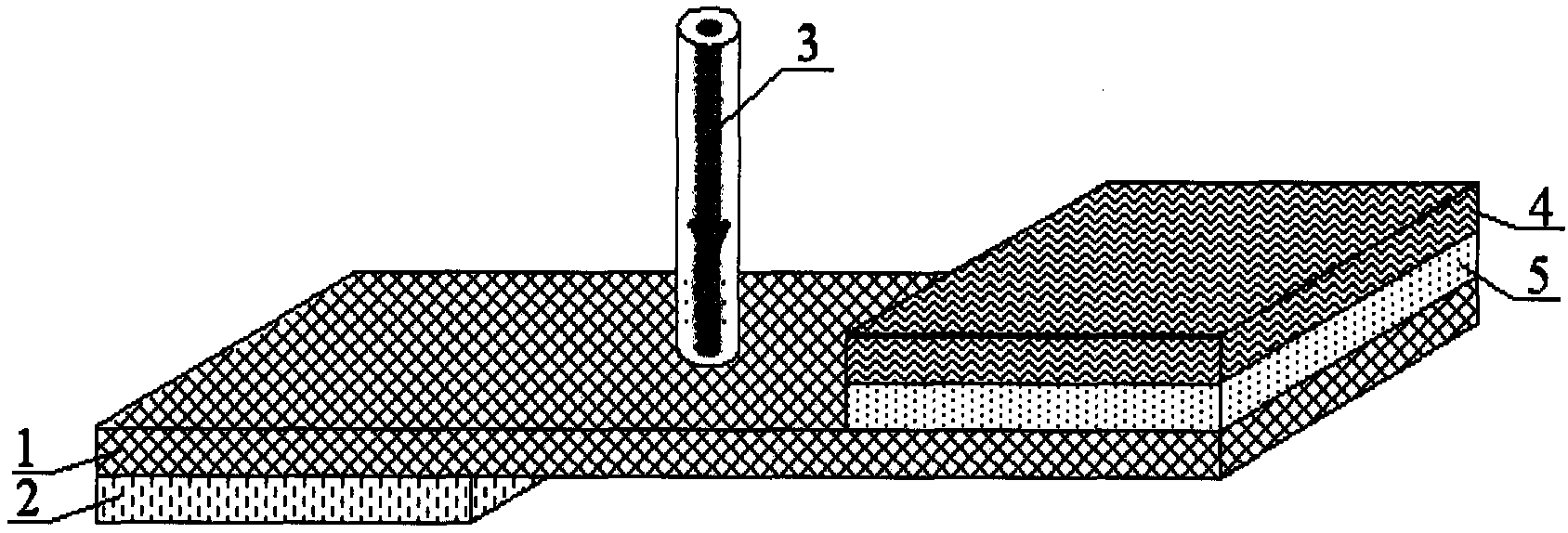

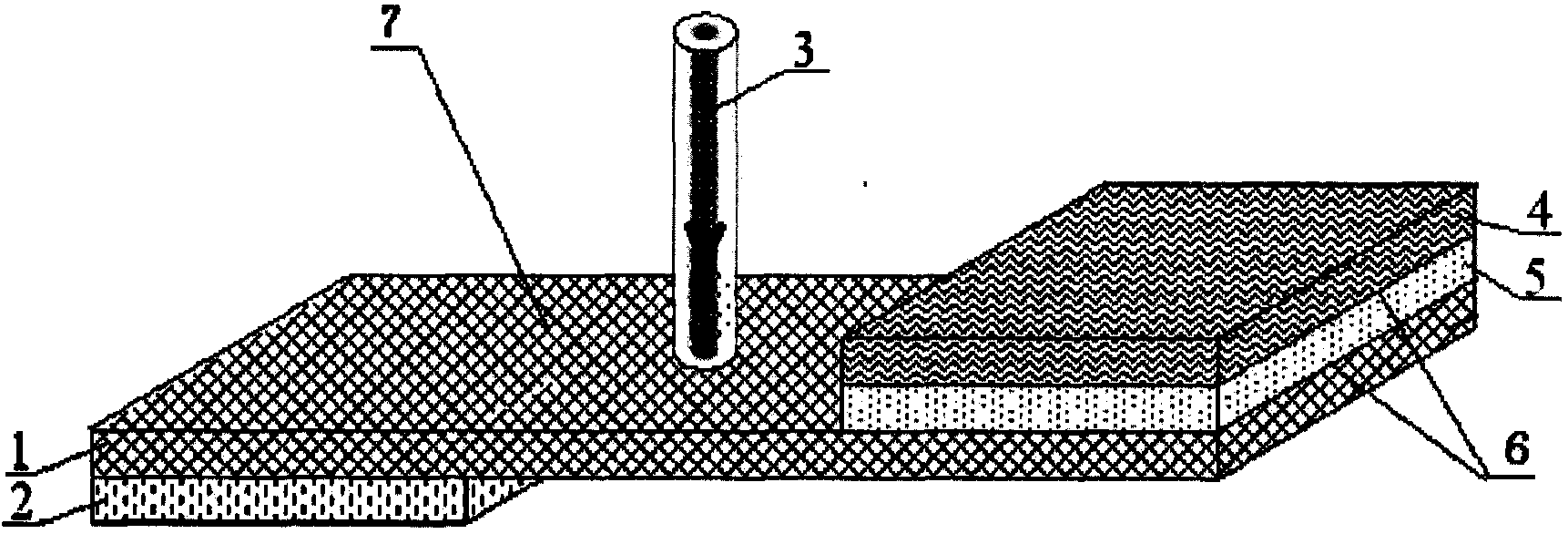

[0014] A photoconductive diamond film switch, comprising a semiconductor film 1, a photoconductive switch negative pole 4 and a photoconductive switch positive pole 2, the photoconductive switch negative pole 4 is connected to the semiconductor film 1, and the photoconductive switch positive pole 2 is connected to the semiconductor film 1, characterized in that, A layer of diamond film 5 is added between the negative electrode 4 of the photoconductive switch and the semiconductor film 1, the positive electrode 2 of the photoconductive switch and the negative electrode 4 of the photoconductive switch are respectively connected to both sides of the semiconductor film 1, and the positive electrode 2 of the photoconductive switch is separated from the negative electrode 4 of the photoconductive switch. distance.

[0015] A metal transition layer 6 is added between the negative electrode 4 of the photoconductive switch and the diamond film 5 and between the semiconductor thin film 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com