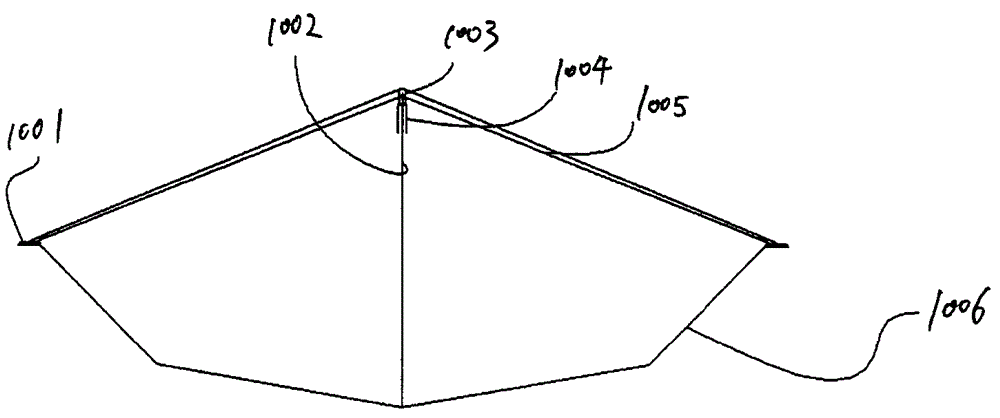

Assembled double-layer-film aquaculture greenhouse

A greenhouse and double-layer technology, applied in fish farming, application, climate change adaptation, etc., can solve problems such as long construction period, low material recovery rate, and poor thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

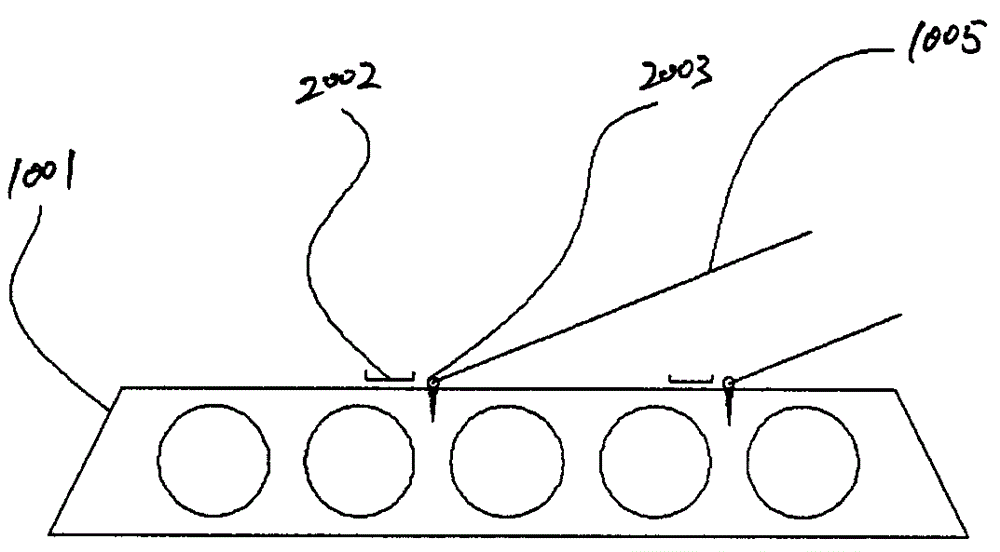

[0025] First, the excavator digs out the main body of the culture pond, the slope of the four walls of the culture pond is α, 40°≤α≤60°, the slope of one side of the bottom of the culture pond is β, 10°≤β≤15°, the four walls of the culture pond and The bottom of the pool forms double slopes and is paved with geomembrane. A row of cement poles is buried in the center of the breeding pond. Except for the two ends of the breeding pond, a brick wall is built between the cement poles in the middle. The brick wall is 2.5 meters high. Together with the cement poles, the breeding pond is divided into two halves. Driven by the type aerator, the water flow in the breeding pond forms a circulation, which is conducive to sewage collection and drainage.

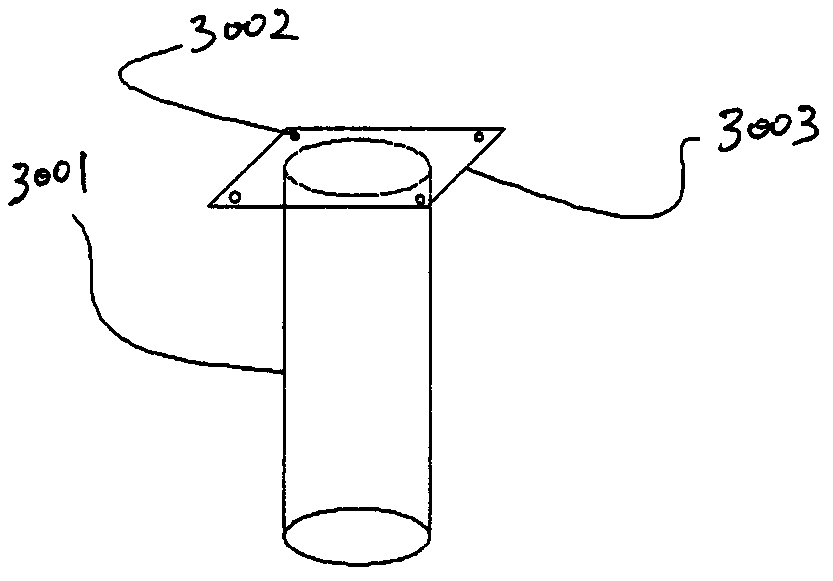

[0026] Lay prefabricated floor slabs on the brick wall as a walkway for the breeding workers to work, especially set a cantilever beam before and after the cement pole, and erect a prefabricated floor slab of suitable length on the cantil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com