Force couple type telescopic clamping device of manipulator

A technology of a clamping device and a telescopic device, which is applied in the field of manipulators, can solve the problems of the connection between the clamping device and the arm being easily damaged, the control system is complex, and the space is large, and the time required for loading and unloading materials is short and the positioning accuracy is high. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

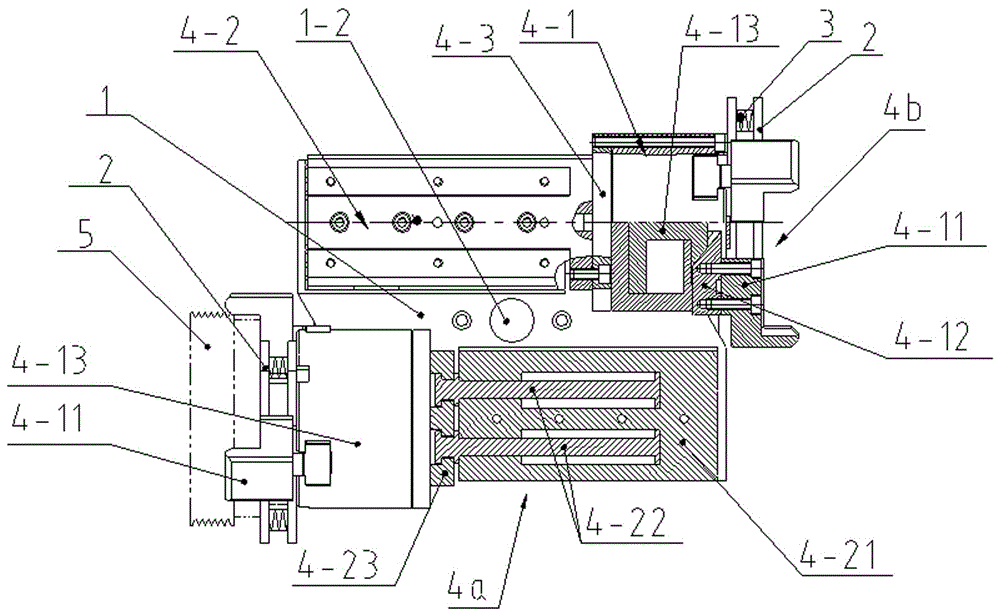

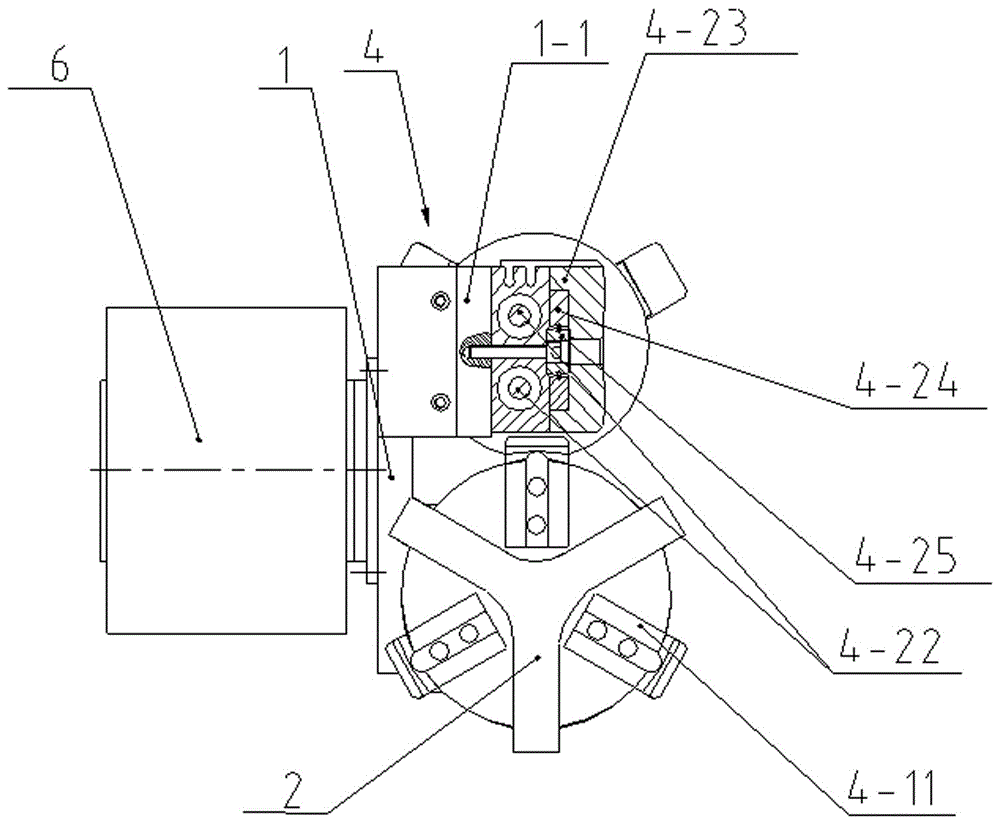

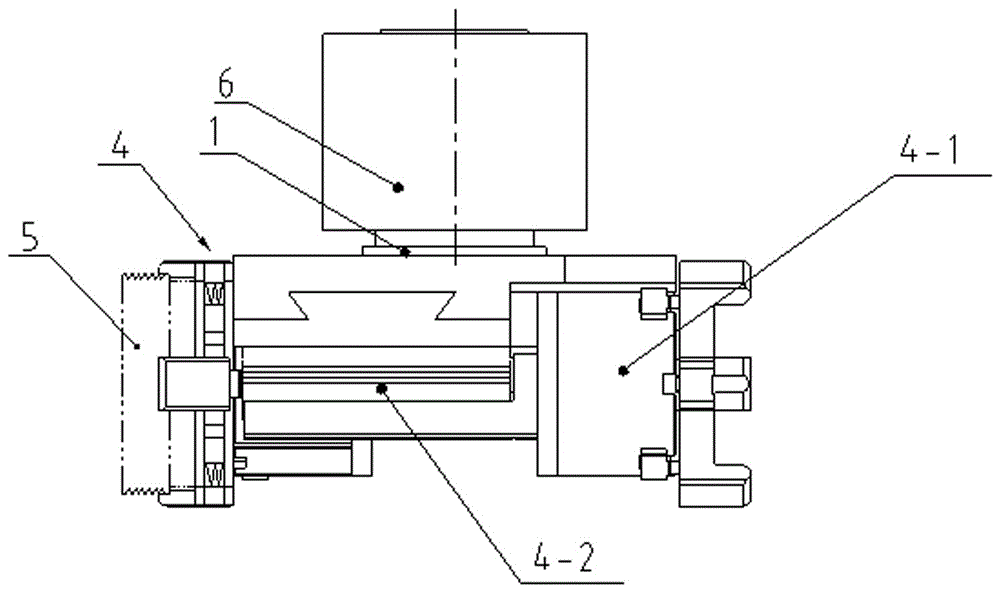

[0022] see Figure 1 to Figure 4 The shown force couple telescopic clamping device of a manipulator includes a mounting bracket 1 for installation on the manipulator, and a pair of telescopic clamping devices 4 arranged symmetrically with the center of the mounting bracket 1 are fixed on the mounting bracket 1 , one of which is a telescopic clamping device 4a for feeding, and the other is a telescopic clamping device 4b for unloading, and the pair of telescopic clamping devices 4 are all composed of telescopic device 4-2 and telescopic device 4 -2 connected clamping claws 4-1, the telescopic device 4-2 is used to drive the clamping claws 4-1 to extend outwards and retract inwards, and the clamping claws 4-1 are used For clamping and loosening the workpiece; the axes of the telescopic clamping device 4a for loading and the telescopic clamping device 4b for unloading ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com