Special electric cable manufacturing sewage treatment system

A technology for sewage treatment system and special cable, applied in the field of cables, can solve problems such as complicated operation, and achieve the effect of high evaporation efficiency, saving operation cost and large amount of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

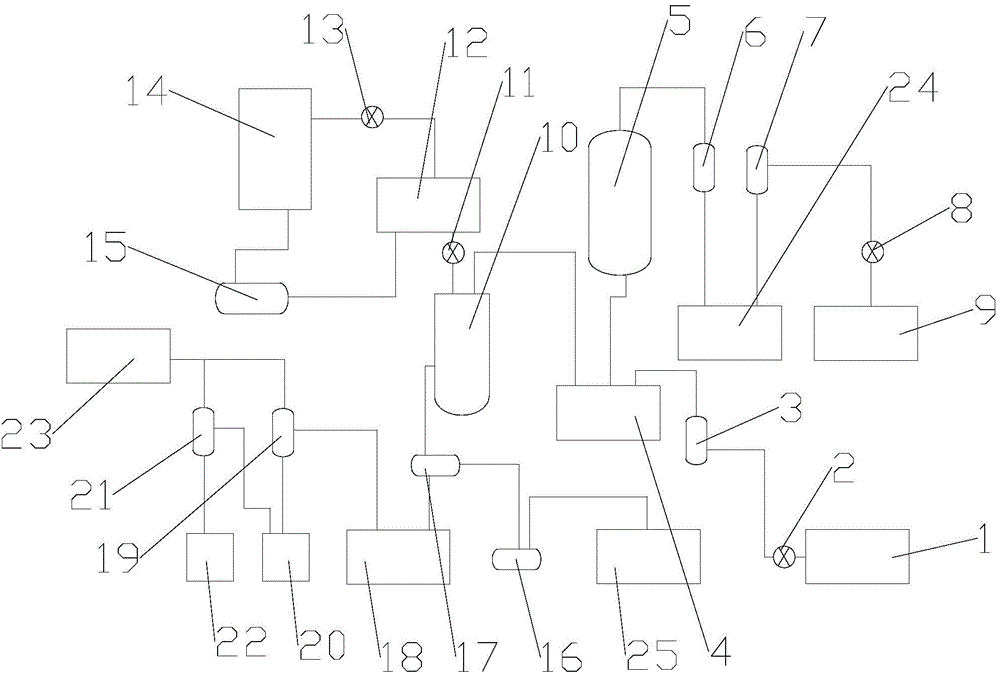

[0014] This embodiment includes a waste liquid storage tank 1, the waste liquid treatment tank 1 is connected with a pressure filter 3, the pressure filter 3 is connected with a first temporary storage tank 4, the first temporary storage tank 4 is connected with a thin-film evaporator 5, and the thin-film evaporator Device 5 is connected with moisture separator 6, and moisture separator 6 is connected with water seal tank 24, and water seal tank 24 is connected with jet condenser 7, and jet condenser 7 is connected with clean water pool 9, and first temporary storage tank 4 is also connected with Frozen crystallization tank 10, the bottom of the frozen crystallization tank 10 is connected with a tipping bucket suction filter 17, the tipping bucket suction filter 17 is connected with a regeneration acid tank 16, the regeneration acid tank 16 is connected with a second temporary storage tank 25, and the top of the freezing crystallization tank 10 is connected with a The rotary tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com