Steel-slag concrete

A technology of steel slag concrete and steel slag stone, which is applied in the field of concrete construction and steel slag concrete construction, can solve the problems of weak surface strength of steel slag, large ratio of raw materials, insufficient structural strength, etc., and achieve good economic benefits, reduce pollution, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

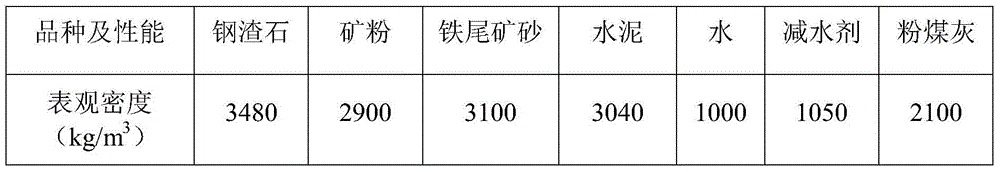

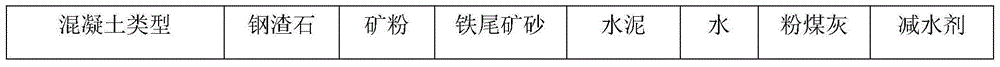

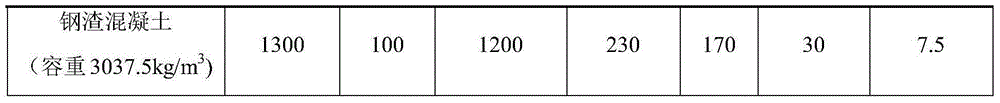

[0042] According to the technical requirements of Class II in JGJ52-2006 "Sand and Stone Quality and Inspection Method Standards for Ordinary Concrete", the raw materials are preliminarily screened, and the impurities in steel slag ore and iron ore tailings are removed. Weigh the raw materials according to the ratio of parts by volume in the table below to make 1m 3 Steel slag concrete, the later maintenance of steel slag concrete is the same as that of ordinary concrete.

[0043] Table 3 Raw material distribution ratio of steel slag concrete

[0044] Number \ Raw material

Steel slag

mineral powder

iron tailings

water

Example 1

1500

120

1400

250

200

40

10

Example 2

1100

80

1100

220

180

20

12

Example 3

1200

110

1300

240

150

50

9

Example 4

1400

90

1000

225

160

10

10

Example 5

1300

100

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com