A five-column double-strand feed method for decarburization of a pyrolysis gasoline hydrogenation unit

A decarbonization five-tower, hydrogenation device technology, applied in refining to remove heteroatoms, etc., can solve the problems of insufficient utilization of low-temperature heat, large device load, etc., to facilitate capacity expansion and transformation, reduce emissions, and reduce volatile emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

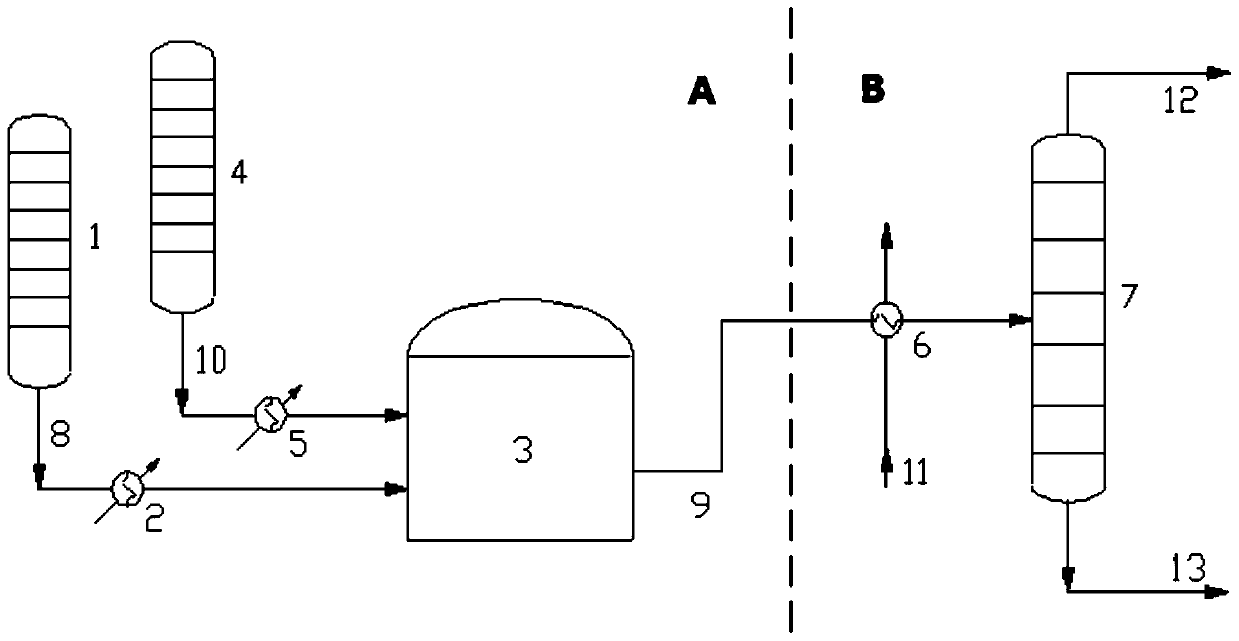

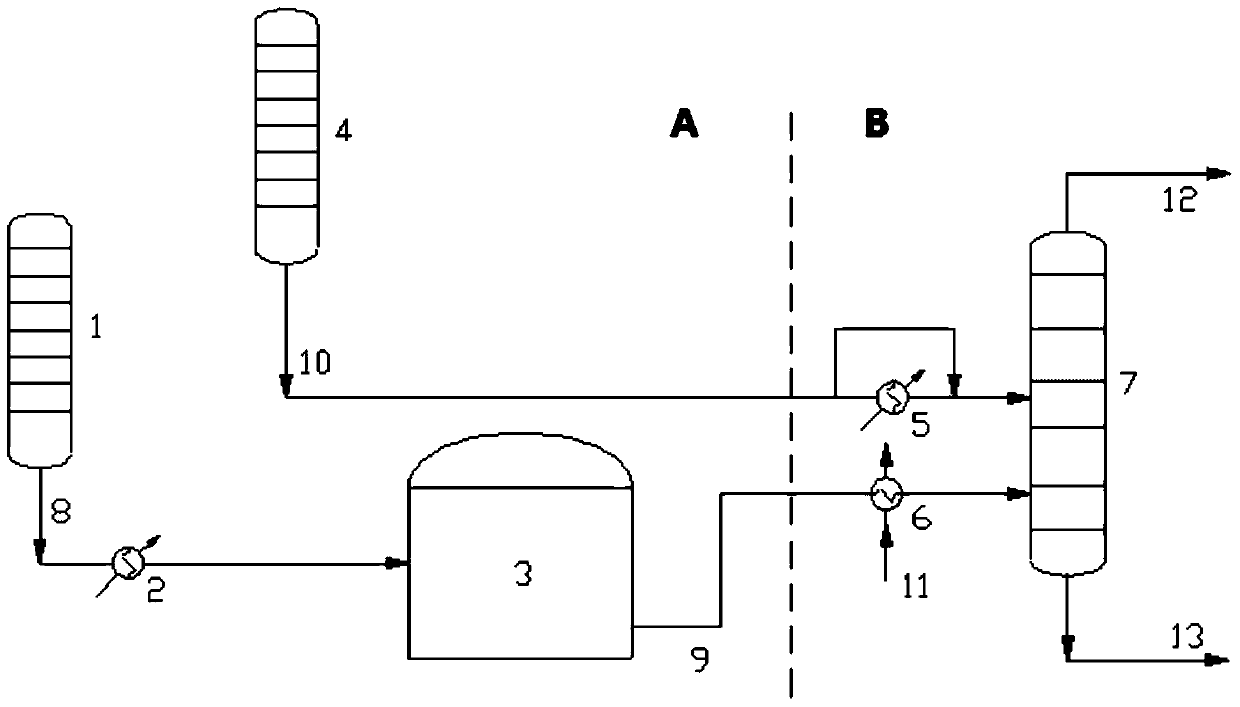

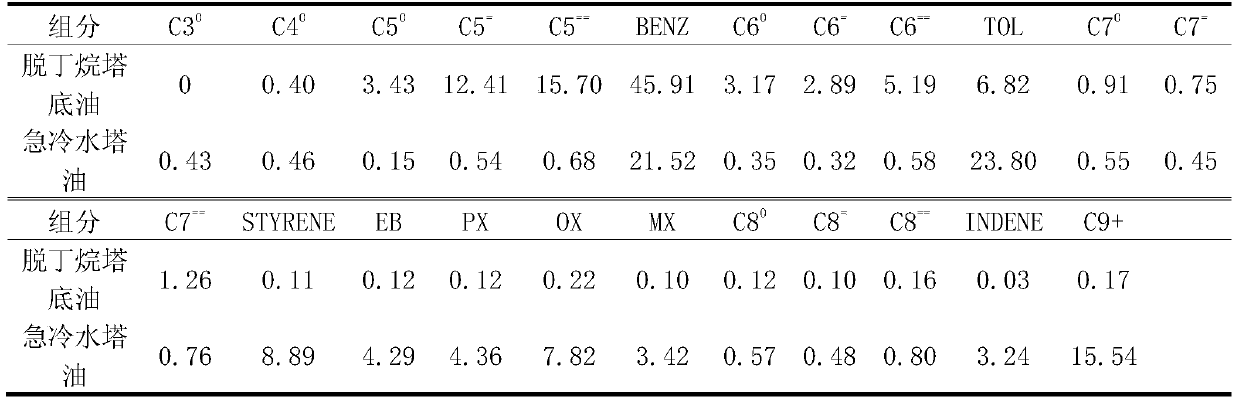

[0032] like figure 2 As shown, the debutanizer bottom oil 10 in the boundary area of the ethylene unit is directly sent to the butane tower bottom oil cooler 5 before the decarbonization fifth tower in the pyrolysis gasoline hydrogenation unit, and enters the decarburization fifth after controlling the temperature at 100°C. The feed port in the middle of the tower 7 enters the tower; the quenched water tower oil 8 is cooled by the cooler 2, and then enters the tank area 3 for static dehydration, and the dehydrated quenched water tower oil 9 is sent to the pyrolysis gasoline hydrogenation unit, and enters the decarbonization five Before tower 7, heat exchange 6 is performed with high-temperature hydrogenated gasoline 11, and finally enter the tower at the feed inlet in the middle of the stripping section of decarbonization fifth tower 7.

[0033] The pressure at the top of the decarburization fifth tower is 90kpag, and the temperature at the bottom of the tower is 126°C. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com