Heavy oil modified viscosity reduction method and application

A heavy oil modification and viscosity reduction technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of poor stability and high oil viscosity, achieve good stability, reduce crude oil viscosity, and ensure long cycle. The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

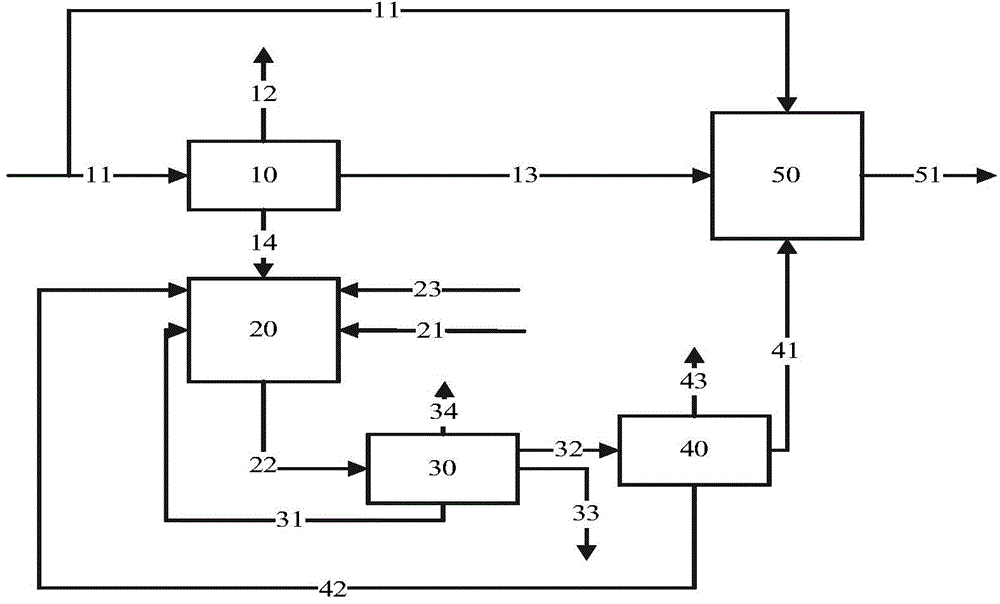

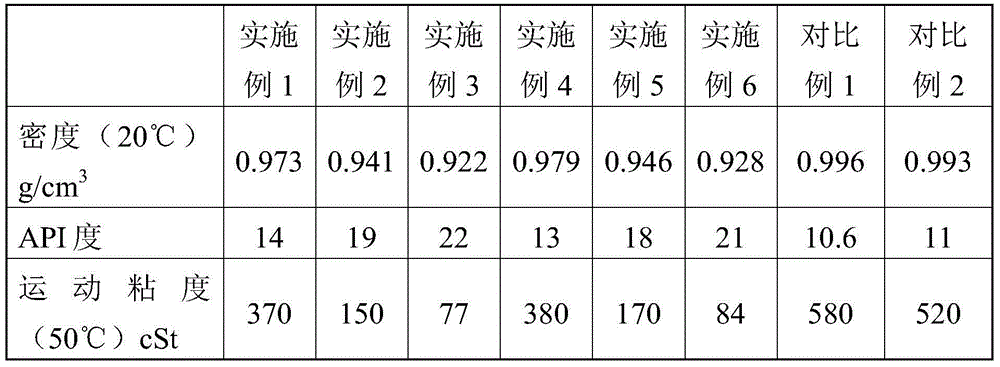

[0043] Suspension-bed hydrogenation reaction is carried out after the Venezuelan extra-heavy oil wellhead oil is distilled under the conditions of temperature 390°C, pressure 8MPa, space velocity 0.8h -1 , the ratio of hydrogen to oil is 500:1, the conversion rate of the suspension bed hydrogenation is 10%, and the suspension bed hydrogenation can operate stably for a long period of time at this low conversion rate.

[0044] The reacted product 22 enters the separator 30 after being filtered, and the gas phase 34 and the liquid phase 32 are separated, and the liquid phase enters the fractionation tower 40, and the fractionation tower fractionates the fraction greater than 540°C and circulates it back to the reactor 20, and fractionates the fraction less than 540°C , to enter the blending device. The reaction results are shown in Table 2.

Embodiment 2

[0046] Suspension bed hydrogenation reaction is carried out after the Venezuelan super heavy oil wellhead oil is distilled under the conditions of temperature 410℃, pressure 8MPa, space velocity 0.8h -1 , the ratio of hydrogen to oil is 500:1, the conversion rate of the suspension bed hydrogenation is 20%, and the suspension bed hydrogenation can operate stably for a long period of time at this low conversion rate.

[0047] The reacted product 22 enters the separator 30 after being filtered, and the gas phase 34 and the liquid phase 32 are separated, and the liquid phase enters the fractionation tower 40, and the fractionation tower fractionates the fraction greater than 540°C and circulates it back to the reactor 20, and fractionates the fraction less than 540°C , to enter the blending device. The reaction results are shown in Table 2.

Embodiment 3

[0049] Suspension-bed hydrogenation reaction is carried out after the Venezuelan extra-heavy oil wellhead oil is distilled under the conditions of temperature 425°C, pressure 8MPa, and space velocity 0.8h -1 , the ratio of hydrogen to oil is 500:1, the conversion rate of the suspension bed hydrogenation is 20%, and the suspension bed hydrogenation can operate stably for a long period of time at this low conversion rate.

[0050] The reacted product 22 enters the separator 30 after being filtered, and the gas phase 34 and the liquid phase 32 are separated, and the liquid phase enters the fractionation tower 40, and the fractionation tower fractionates the fraction greater than 540°C and circulates it back to the reactor 20, and fractionates the fraction less than 540°C , to enter the blending device. The reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com