Treating solution for nanometer holes in stainless steel surface and application method of treating solution

A technology of nano-holes and application methods, applied in the field of metal surface treatment, can solve the problems of difficulty in preparing nano-hole structures on the surface of stainless steel, and achieve the effects of easy popularization and application, simple preparation operation process and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

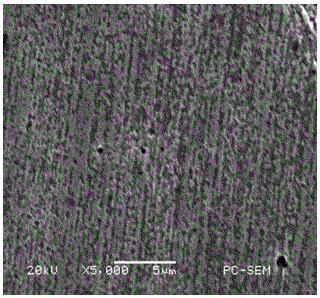

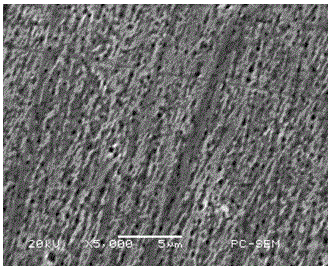

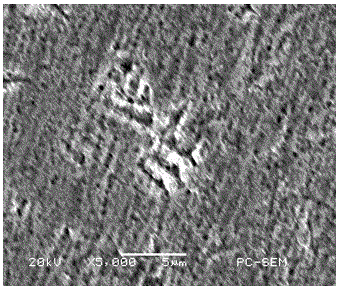

Image

Examples

Embodiment 1

[0035] Embodiment 1: the application method of stainless steel surface nano-hole treatment liquid, the steps are as follows:

[0036] 1. Stainless steel surface pretreatment

[0037] 1) After preliminary degreasing and decontamination of stainless steel with alcohol, rinse with deionized water and dry;

[0038] 2) Use 600#, 800# and 1000# sandpaper to polish the stainless steel surface in sequence until the surface finish required for metallographic observation is obtained;

[0039] 3) After cleaning the stainless steel with alcohol under ultrasonic waves, clean the stainless steel with acetone for 5 minutes under ultrasonic waves, and then ultrasonically clean with deionized water for 10 minutes;

[0040] 4) Put the stainless steel into the blast drying oven, after drying for 25 minutes, close the drying oven, and take out the stainless steel after cooling to room temperature.

[0041] 2. Treatment liquid reprocessing:

[0042] Soak the stainless steel treated in step 1 in...

Embodiment 2

[0044] Embodiment 2: the application method of stainless steel surface nano hole treatment liquid, the steps are as follows:

[0045] 1. Stainless steel surface pretreatment

[0046] 1) After preliminary degreasing and decontamination of stainless steel with alcohol, rinse with deionized water and dry;

[0047] 2) Use 800#, 1000# and 1200# sandpaper to polish the stainless steel surface in sequence until the surface finish required for metallographic observation is obtained;

[0048] 3) After cleaning the stainless steel with alcohol under ultrasonic waves, clean the stainless steel with acetone for 8 minutes under ultrasonic waves, and then ultrasonically clean with deionized water for 13 minutes;

[0049] 4) Put the stainless steel into the blast drying oven, after drying for 30 minutes, close the drying oven, and take out the stainless steel after cooling to room temperature.

[0050] 2. Treatment liquid reprocessing:

[0051] Soak the stainless steel treated in step 1 i...

Embodiment 3

[0053] Embodiment 3: the application method of stainless steel surface nano hole treatment liquid, the steps are as follows:

[0054] 1. Stainless steel surface pretreatment

[0055] 1) After preliminary degreasing and decontamination of stainless steel with alcohol, rinse with deionized water and dry;

[0056] 2) Use 600#, 1000# and 1400# sandpaper to polish the stainless steel surface in sequence until the surface finish required for metallographic observation is obtained;

[0057] 3) After cleaning the stainless steel with alcohol under ultrasonic waves, clean the stainless steel with acetone for 10 minutes under ultrasonic waves, and then ultrasonically clean with deionized water for 15 minutes;

[0058] 4) Put the stainless steel into the blast drying oven, after drying for 35 minutes, close the drying oven, and take out the stainless steel after cooling to room temperature.

[0059] 2. Treatment liquid reprocessing:

[0060] Soak the stainless steel treated in step 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com