Limit-level disconnection type double helix well bottom sand fluid mixing tubular column

A double helix, limited technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problem of long movement displacement, and achieve the effect of strong practicability, improved swirl effect, and remarkable application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

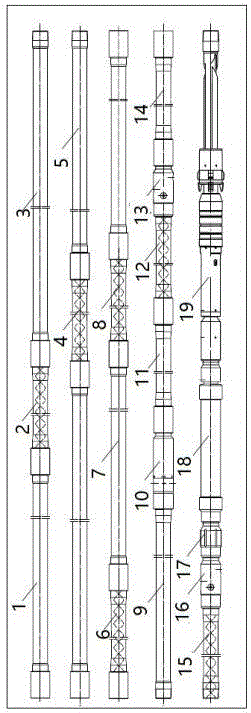

[0025] The present invention provides a figure 1 As shown in the finite-stage intermittent double-helix sand-fluid mixing string at the bottom of the well, the present invention adds double-helix nipples at different positions (certain tubing length) of the multi-stage cluster jet fracturing string to make the high-speed sand-carrying liquid flow The state of helical swirl flow is generated when passing through the first-stage double-helix sub-joints. After passing through the double-helix sub-joints, the high-speed sand-carrying liquid still moves forward in the state of helical swirl flow, and the displacement of the movement is exactly between each two-stage double-helix sub-joints. The length of the tubing between the oil pipes, so as to keep the high-speed sand-carrying fluid moving in a spiral swirl state in the long horizontal section, until it moves to the upper and lower stream injectors of the clustered perforation, effectively perforating and subsequent fracturing. ...

Embodiment 2

[0032] On the basis of the above-mentioned embodiments, in this embodiment, an upper adjustment nipple 11 is connected between the upper double helix nipple 12 and the nth-stage oil pipe 9, and the upper adjustment nipple 11 and the n-th-stage oil pipe 9 Connection via safety connector 10.

[0033] The lower double-helix short joint 15 is connected to the upper water jet 13 through the lower adjustment joint 14 .

[0034] A check valve 17 is arranged between the lower hydraulic injector 16 and the telescopic compensator 18 .

[0035] The first stage oil pipe 1 and the nth stage oil pipe 9 have the same structure, both are Φ73mm oil pipes.

[0036] The upper adjusting sub-joint 11 and the lower adjusting sub-joint 14 have the same structure, both are Φ73mm adjusting sub-joints.

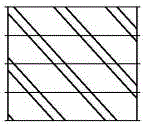

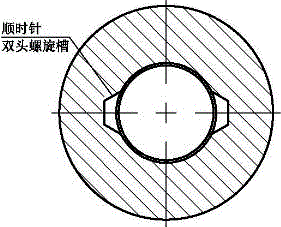

[0037] Such as figure 2 , image 3 As shown, the length of the above-mentioned multiple double helix short joints is 2500mm, the outer diameter is 80mm, and the inner diameter is 40mm.

[0038] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com