Flue gas rotational flow device for flue gas desulfurization and use method thereof

A flue gas and cyclone technology, which is applied in the direction of separation methods, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problem that the surface cleanliness of the swirl plate cannot be guaranteed, the swirl effect cannot be achieved, and the flue gas cannot be demisted and other problems, to achieve the effect of compact structure, strong practicability and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

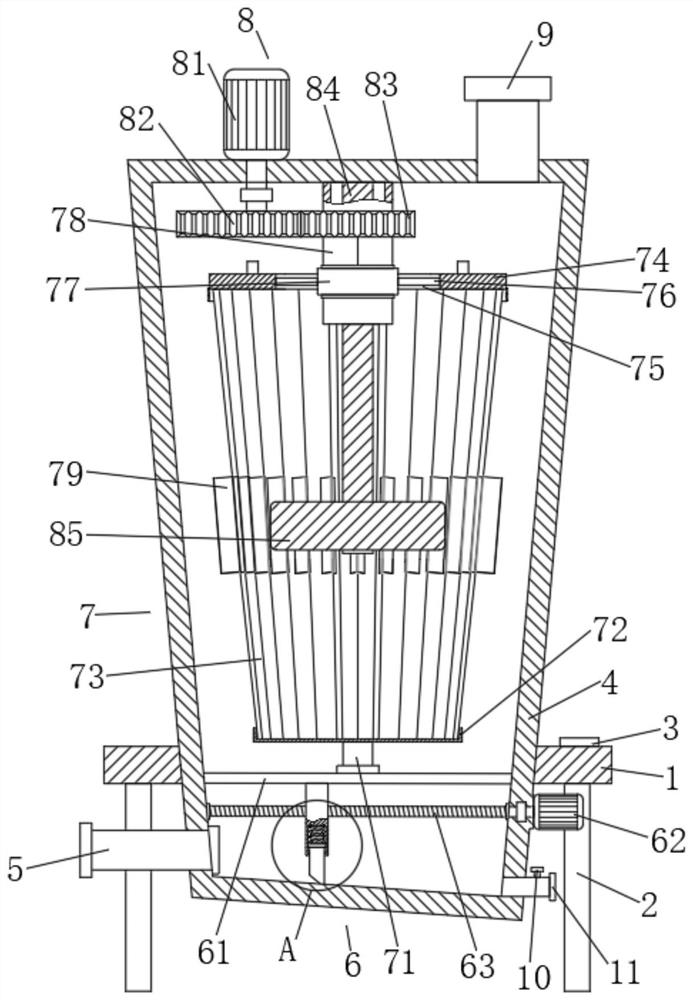

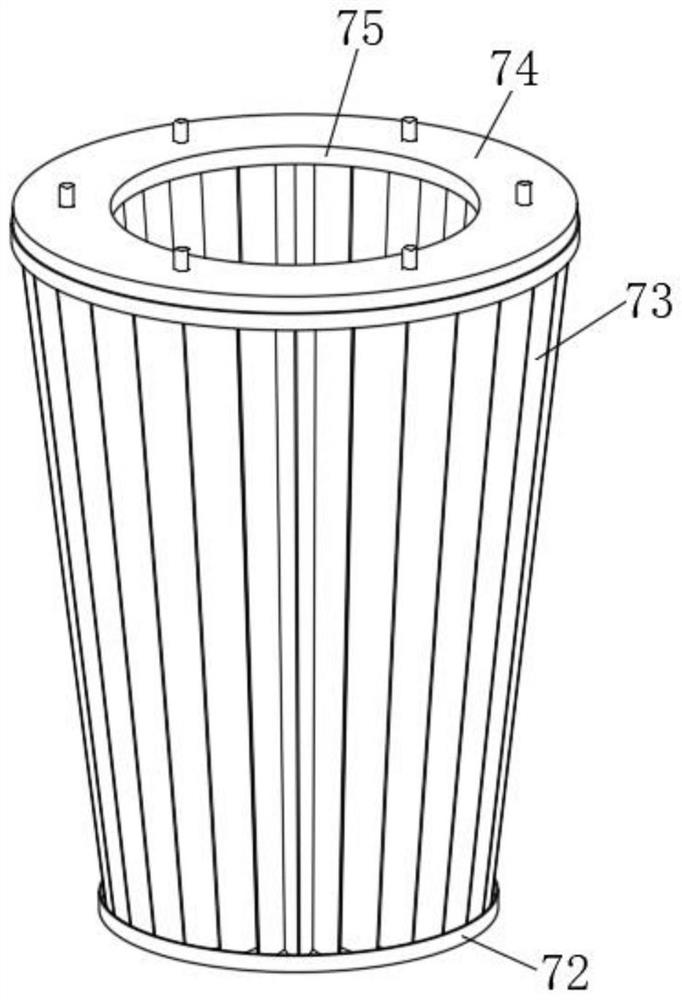

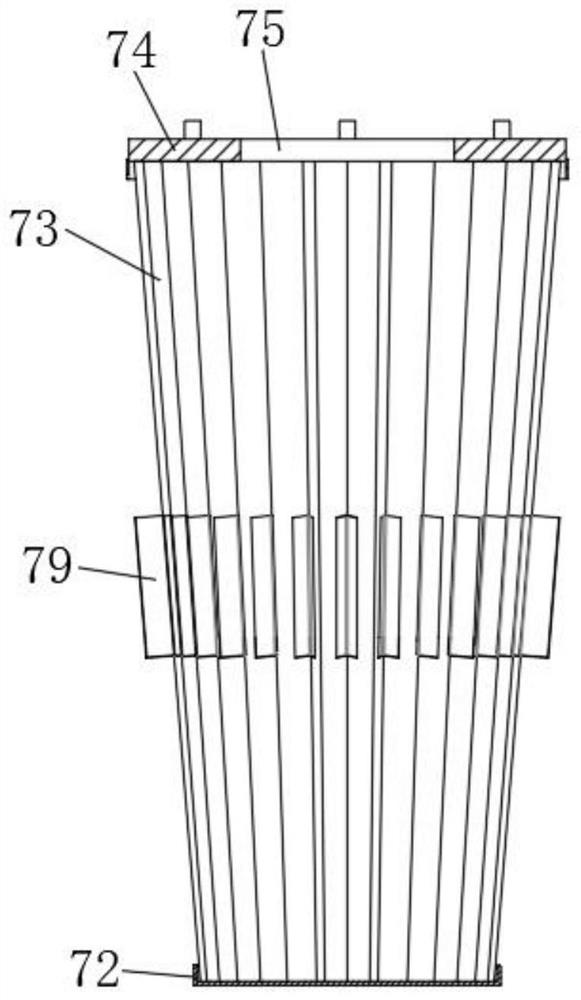

[0030] A flue gas swirling device for flue gas desulfurization, comprising a fixed plate 1, the four corners of the bottom of the fixed plate 1 are fixedly connected with supporting feet 2, and the supporting feet 2 are used to facilitate better stable support of the equipment; One end of the top of the fixed plate 1 is fixedly equipped with a control panel 3, and the top of the fixed plate 1 is fixedly connected with a swirl box 4, and the bottom of the swirl box 4 extends to the bottom of the fixed plate 1, and the swirl box 4 One side of the bottom and below the fixed plate 1 are fixedly connected with an air inlet pipe 5, which facilitates better air intake through the air inlet pipe 5; , through the exhaust pipe 9 to facilitate better exhaust; the bottom of the inner wall of the swirl box 4 is provided with a dust removal mechanism 6, and the inside of the swirl box 4 and above the dust removal mechanism 6 is provided with a swirl mechanism 7 , the top of the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com