A steel piston based on laser welding forming inner cooling oil passage and its processing method

A cooling oil channel and laser welding technology, which is applied to pistons, engine components, machines/engines, etc., can solve problems such as large tolerances in effective height dimensions, affecting the axial dimension of the piston head, and unreliable quality of welded joints, etc., to achieve Improve the cooling effect, overcome the difficulty of processing, and reduce the weight of the piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

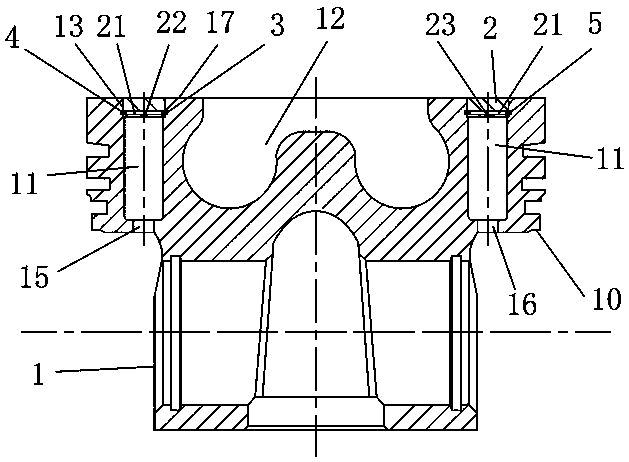

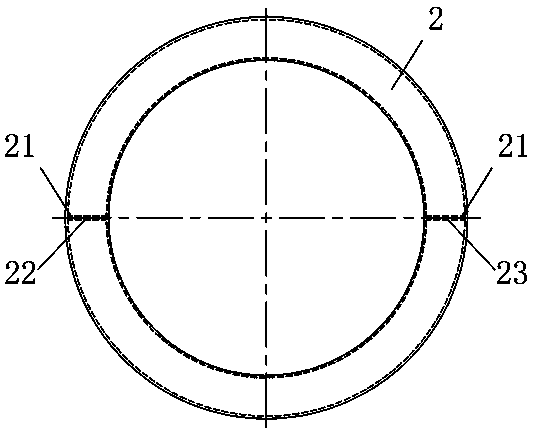

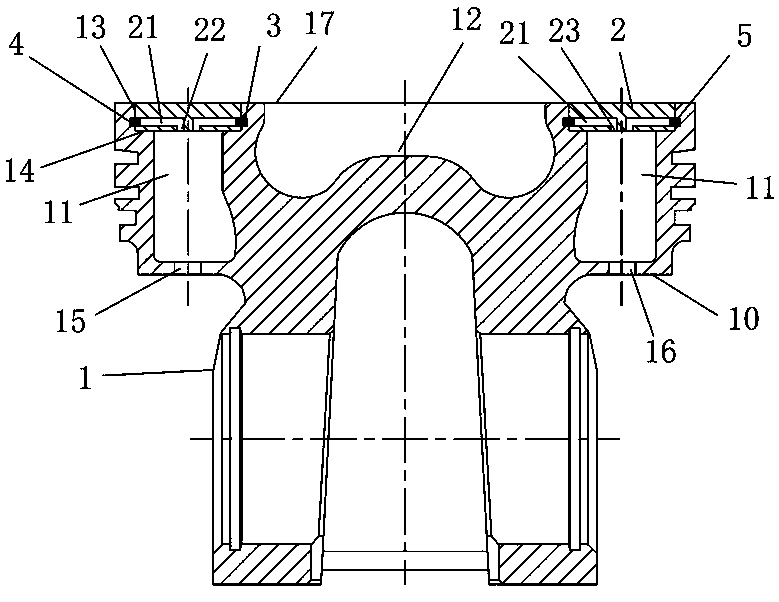

[0037] figure 1 and figure 2It shows the first steel piston embodiment of the present invention based on the laser welding forming inner cooling oil passage, the steel piston includes a piston body 1 and an annular sealing plate 2, and the piston body 1 is provided with an inner cooling oil passage on the piston head 10 11 and the combustion chamber 12, the inner cooling oil passage 11 is arranged around the combustion chamber 12, the piston head 10 is also provided with an oil inlet hole 15 and an oil outlet hole 16 communicating with the inner cooling oil passage 11, and the upper end of the inner cooling oil passage 11 is provided with The annular opening 13 is located at the top 17 of the piston head 10. The annular sealing plate 2 is embedded in the annular opening 13 and connected and fixed by laser welding. It seals the upper end of the internal cooling oil passage 11. The inner and outer rings of the annular sealing plate 2 The inner annular channel 3 and the outer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com