stove burner

A technology for burners and stoves, which is applied to burners, gas fuel burners, combustion types, etc., can solve the problems of easy flame overflowing from the bottom of the pot, increased cost, and large heat loss, and achieves increased residence time and contact area. Processing and material costs, the effect of reducing the contaminated area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

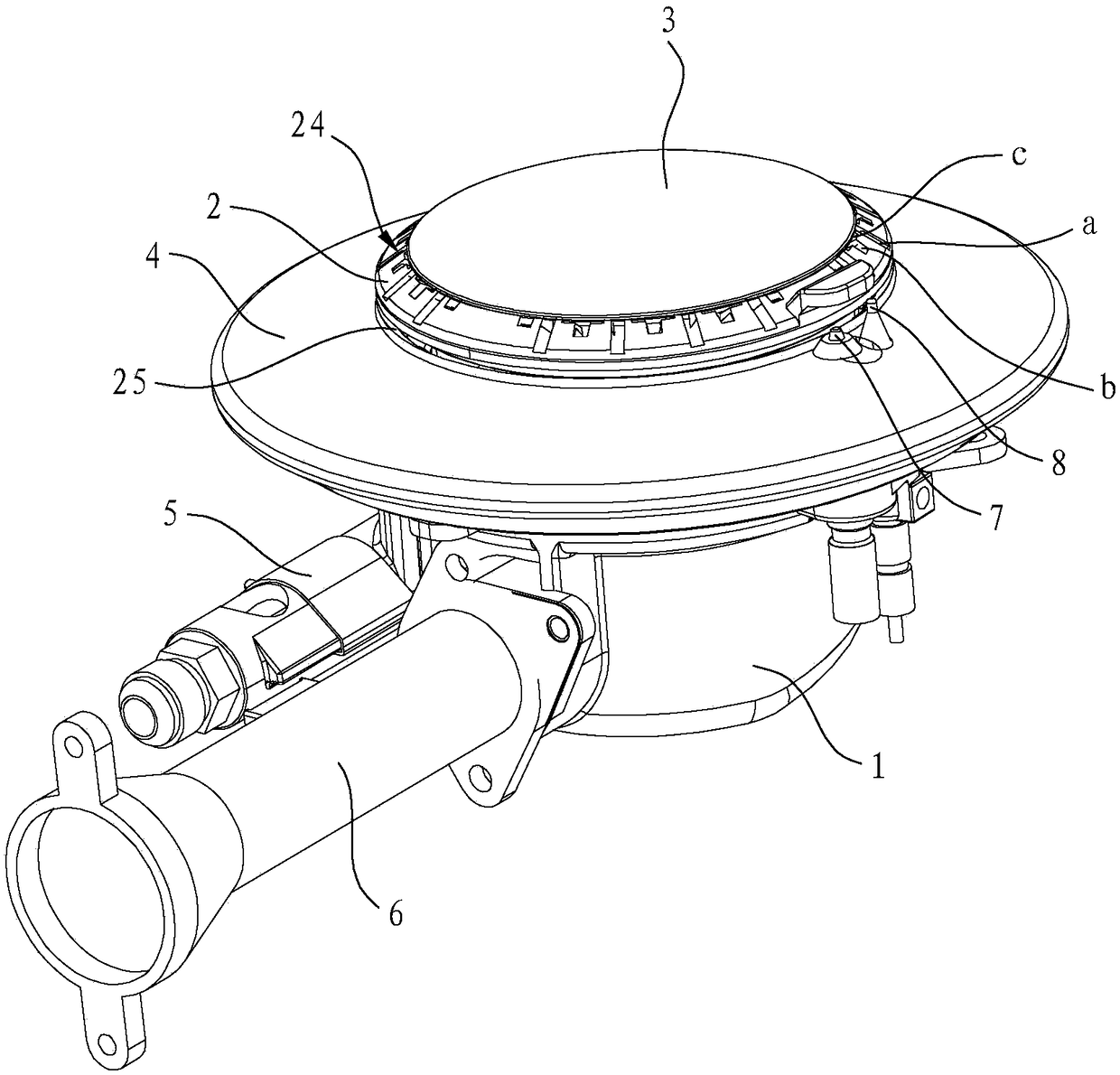

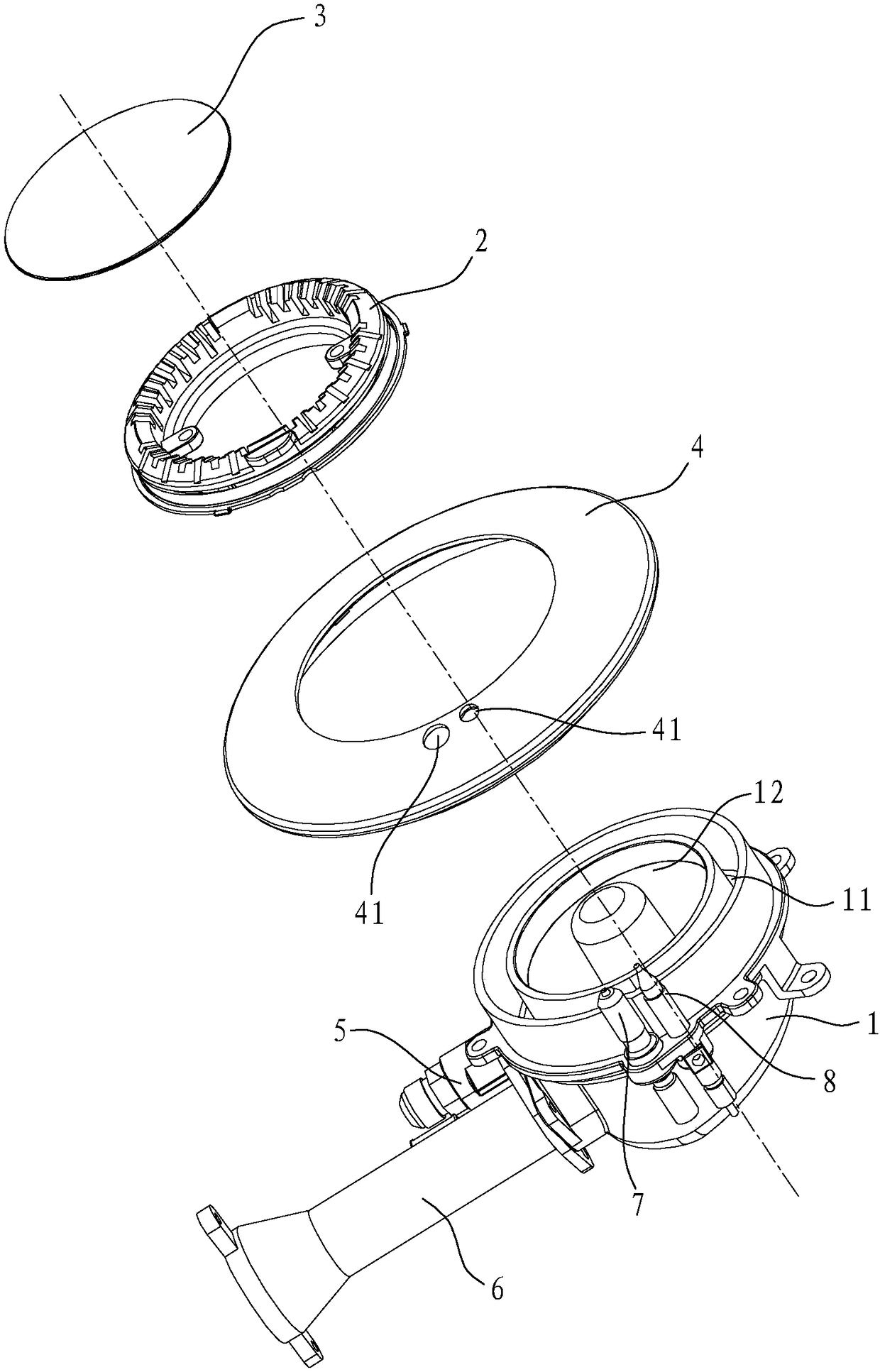

[0035] Such as figure 1 and figure 2 As shown, the stove burner in this embodiment includes a burner head 1, a fire cover 2, a cover plate 3, a decorative ring 4, an outer ring gas injection tube 5, an inner ring gas injection tube 6, an ignition needle 7 and a thermocouple 8 and other components.

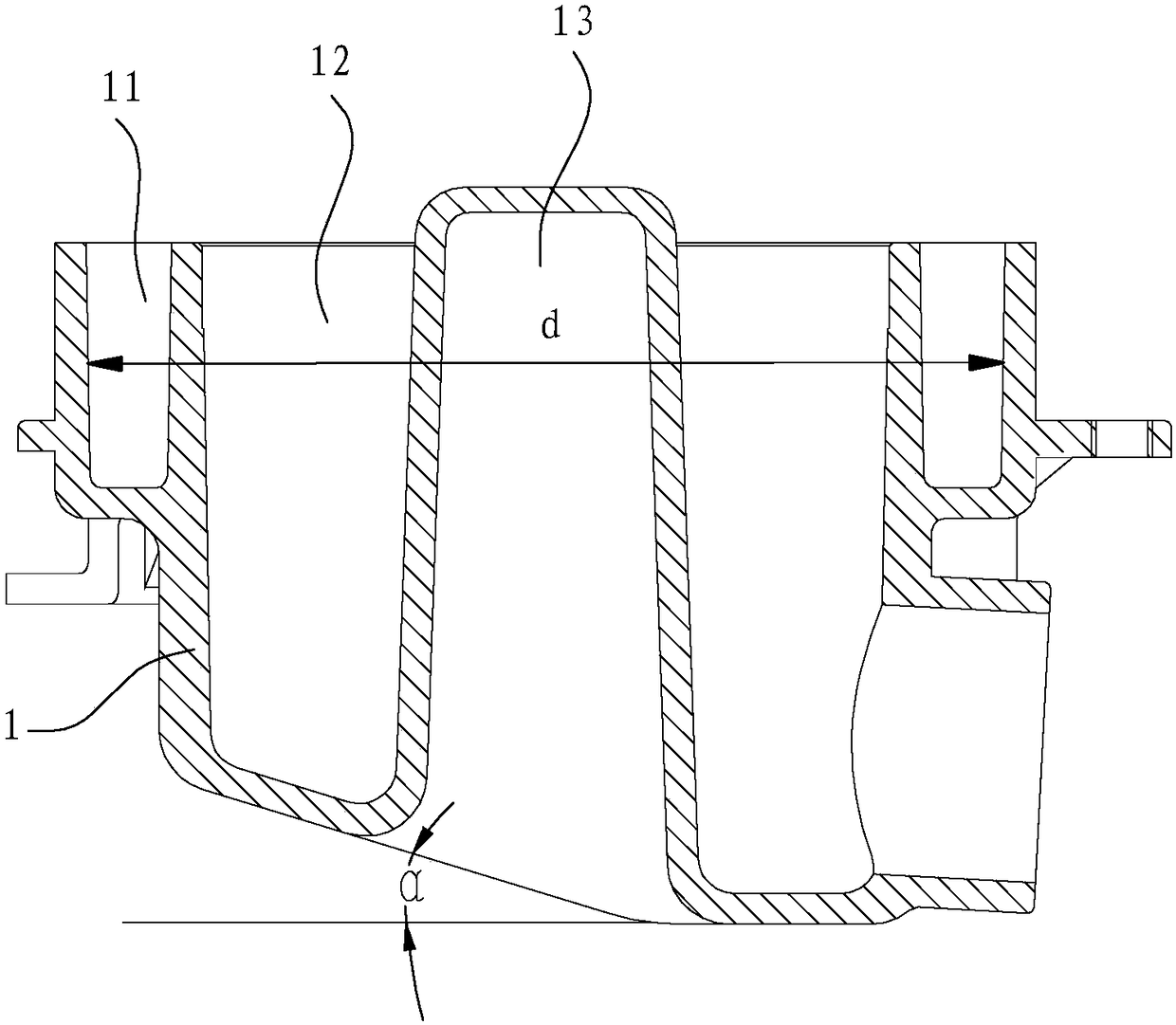

[0036] Such as image 3 As shown, the burner head 1 has an outer ring cavity 11, an inner ring cavity 12 and a cylindrical cavity 13, the cylindrical cavity 13 is concave upward from the bottom of the burner head 1, and the cylindrical cavity 13 is located inside The center of the ring cavity 12. The cylindrical cavity 13 acts as a flow guide, so that the uniformity of the airflow in the burner 1 is better, and the gas mixing effect is better. In addition, a temperature sensor can also be installed in the cylindrical cavity 13 to detect the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com