Syphilis diagnosis chip device with substrate prepared from strong hydrophobic PDMS

A technology of substrates and materials, applied in the field of analysis and testing, can solve the problems such as troublesome operation of the inner surface modification of PDMS microchannel, which has not been properly solved, and difficulty in passing fine liquid flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

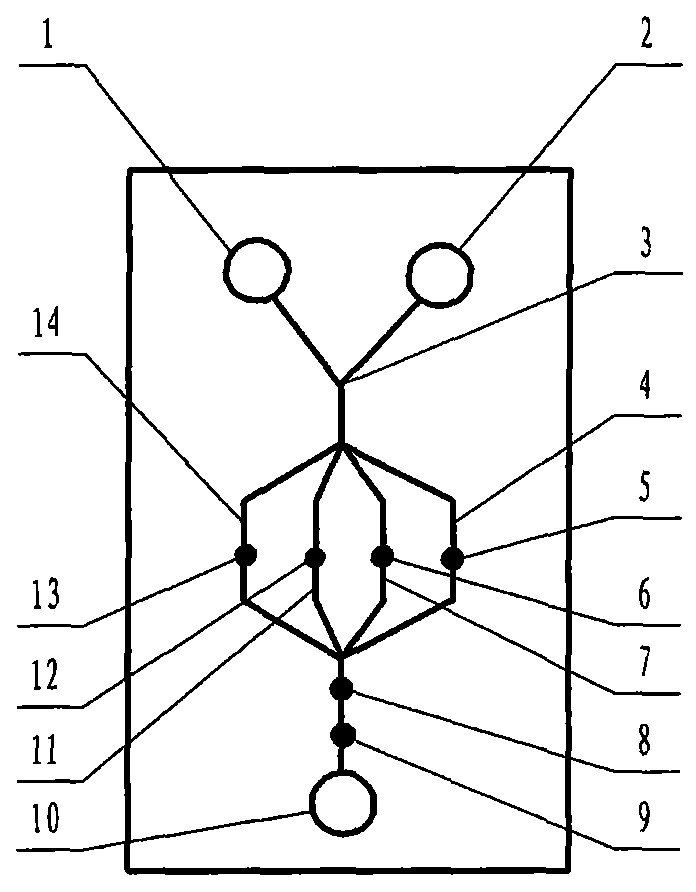

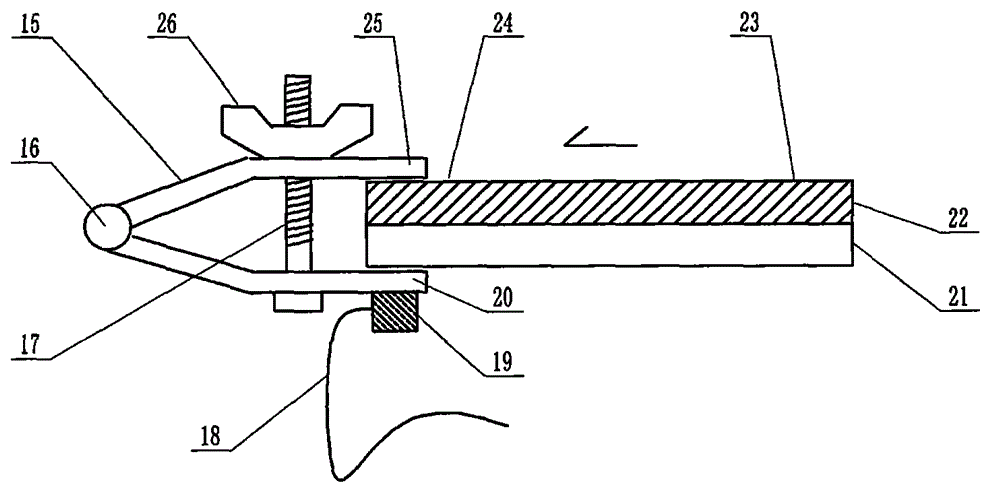

[0054] exist figure 1 and figure 2In the shown embodiment of the present case, the structure of the device includes a multi-channel microfluidic chip, and the structure of the microfluidic chip includes a substrate 22 and a cover sheet 21 that are attached to each other and installed together. The substrate 22 and the cover sheet 21 are plates or sheets, the surface of the substrate 22 facing the cover sheet 21 contains a channel structure formed by a molding process or an etching process, and the substrate 22 also contains a channel structure that is connected to the groove The window structure is connected to the channel structure and penetrates the substrate through a molding process, an etching process or a simple punching process. The substrate 22 and the cover sheet 21 that are attached to each other are jointly constructed to contain a channel structure and a window structure. A microfluidic chip with a liquid pool structure connected to it, the liquid pools are liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com