Temperature control method and device for enrichment pipe

A technology of temperature control device and enrichment tube, which is applied in the field of temperature control of enrichment tube, can solve problems such as unevenness, uneven temperature of enrichment tube, difficulty in installing temperature sensor, etc., and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment proposes a method for temperature control of the enrichment tube, which includes the following steps:

[0035] ①Preparation: Wind the platinum wire evenly on the outer tube wall of the enrichment tube, set the temperature control cycle, and set the required temperature of the enrichment tube.

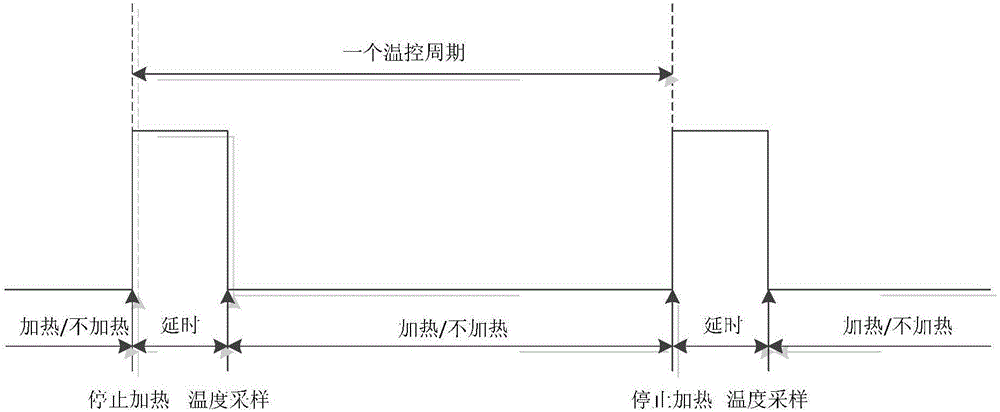

[0036] ②The temperature is collected and heated in one temperature control cycle, and the control sequence diagram is as follows figure 1 Shown: When it is necessary to obtain the temperature of the enrichment tube, first make the platinum wire as the heating element not generate heat and not heat the enrichment tube; then obtain the temperature on the platinum wire as the temperature measuring element after a set time delay value; then use the proportional integral differential algorithm (PID algorithm) to calculate the temperature value on the platinum wire obtained as a temperature measuring element and the temperature required by the enrichment tube to obtain ...

Embodiment 2

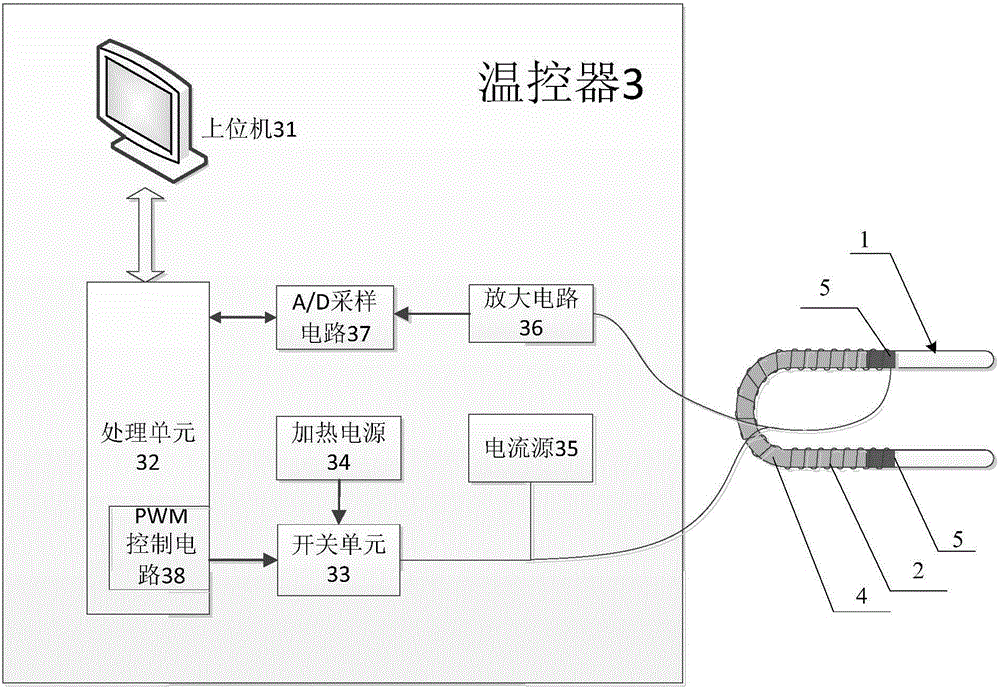

[0040] This embodiment proposes an enrichment tube temperature control device realized by using the enrichment tube temperature control method in the first embodiment above, such as figure 2 As shown, it includes an enrichment tube 1, a platinum wire 2 and a thermostat 3, the platinum wire 2 is evenly wound on the outer tube wall of the enrichment tube 1, the platinum wire 2 acts as a temperature measuring element and a heating element, and the thermostat 3 Connected with the platinum wire 2, the temperature controller 3 is used to obtain the temperature of the platinum wire 2 serving as a temperature measuring element, and is used to control the heating power loaded on the platinum wire 2 serving as a heating element so that the platinum wire 2 is under the heating power Heat the enrichment tube 1.

[0041] In this specific embodiment, the temperature controller 3 is composed of a host computer 31, a processing unit 32, a switch unit 33 capable of withstanding high power cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com