Oil pump controller and oil pump bracket assembly

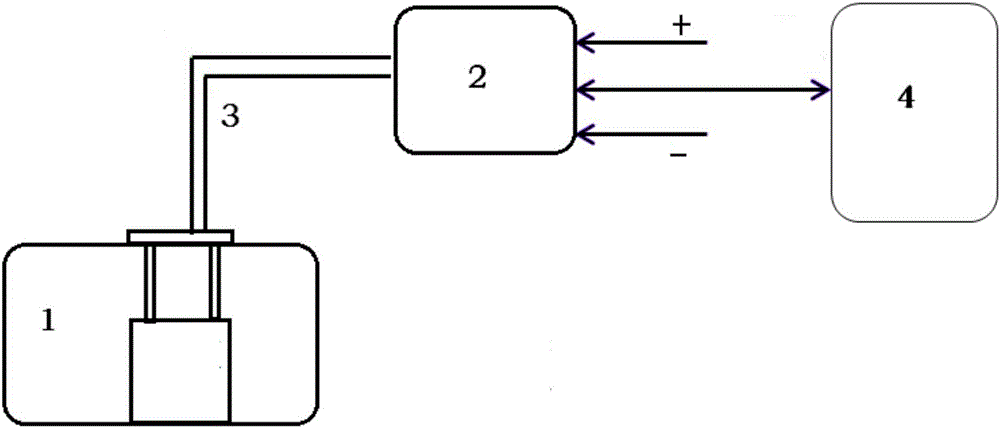

A bracket assembly and controller technology, applied in the direction of pump control, machine/engine, arrangement of circuit components without support structure, etc., can solve the problems of increasing the cost of parts, difficult to arrange other parts, and occupying chassis space, etc., to achieve Ease of after-sales replacement, save space, and save wiring harness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

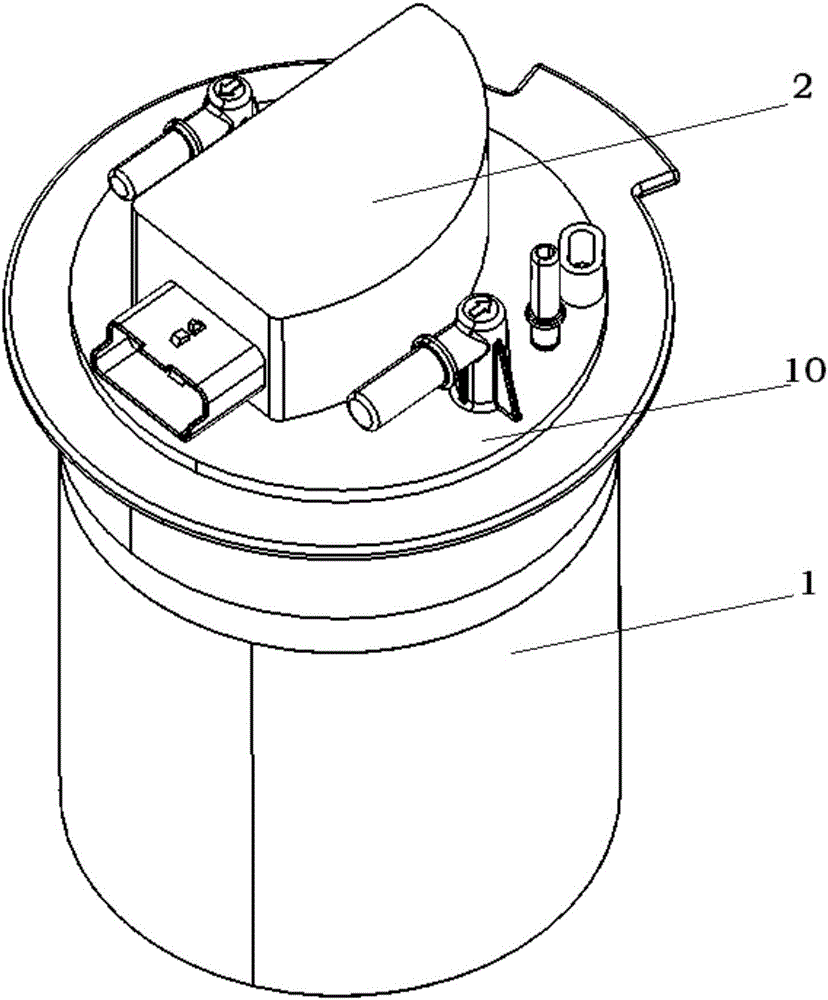

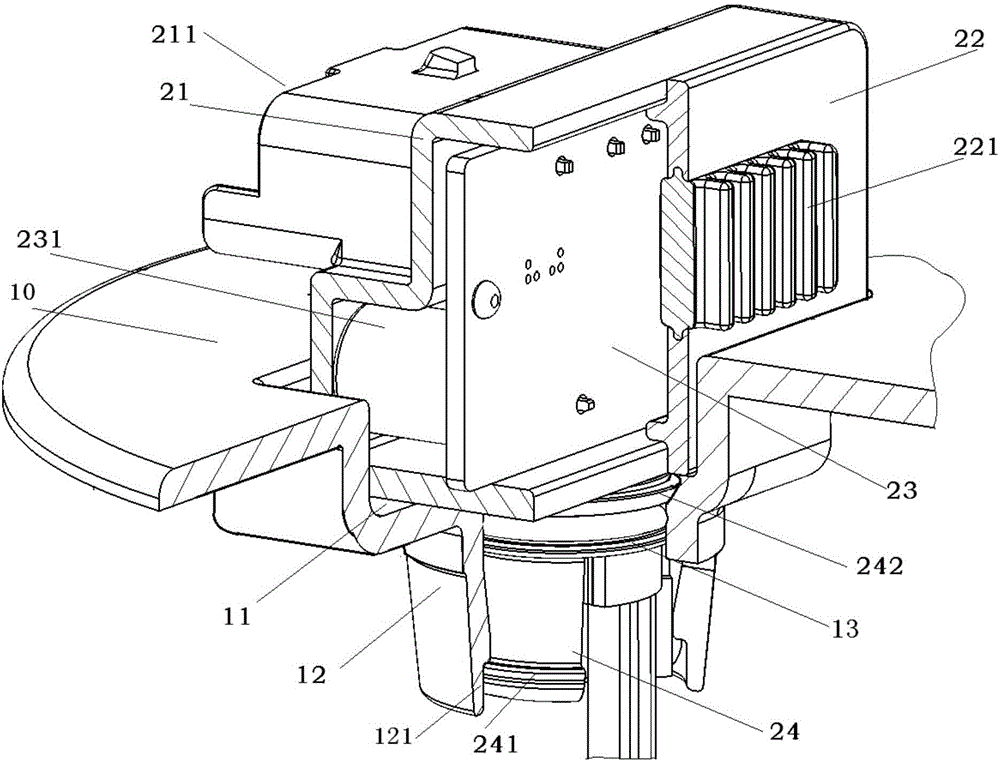

[0054] An oil pump bracket assembly, such as image 3 , Figure 4 , Figure 5 , Image 6 As shown, it includes an oil pump controller and a flange 10;

[0055] The oil pump controller includes a housing, a PCB (printed circuit board) 23, and a flange connector;

[0056] The outer wall of the housing is injection-molded and fixed with a pin (pin) 210;

[0057] The pin (pin) 210 has one end protruding from the outer wall of the housing to form a controller electrical plug 211;

[0058] The PCB board is vertically placed in the cavity of the housing;

[0059] The flange connector is arranged at the lower end of the bottom surface of the housing, and can be assembled and fixed with the flange;

[0060] The flange is provided with a groove, and the bottom of the groove is provided with a mounting hole 12, and the flange connector of the oil pump controller is clamped in the mounting hole.

[0061] Preferably, the oil pump controller is detachably connected to the flange.

[0...

Embodiment 2

[0066] Based on the oil pump bracket assembly of Embodiment 1, such as image 3 , Figure 4 As shown, the controller electric plug 211 of the oil pump controller is located on the side wall of the housing,

[0067] Capacitors and inductors are placed on the side of the PCB 23 close to the electrical plug 211 of the controller, and the capacitors and inductors are located below the pins 210 .

[0068] Preferably, the PCB board 23 includes two edges in the first direction and two edges in the second direction, the length of the edges in the first direction is not longer than the length of the edges in the second direction, and the PCB The plate 23 is placed in the cavity of the housing and one edge in the first direction is located at the upper end of the bottom surface of the housing.

[0069] Under normal circumstances, electronic components are arranged on the PCB board according to the electrical requirements. If the electric plug of the oil pump controller is arranged on ...

Embodiment 3

[0071] Based on the oil pump bracket assembly of Embodiment 1, such as image 3 As shown, the flange 10 is provided with a groove 11;

[0072] The bottom of the groove 11 communicates with a mounting hole 12;

[0073] The flange connector 24 provided at the lower end of the lower wall of the oil pump controller housing is tubular;

[0074] The lower end of the flange connector 24 is provided with a plurality of connector buckles 241 along the circumference.

[0075] The oil pump controller is fitted and assembled with the groove 11 of the flange 10 and the mounting hole 12 through the flange connector 24 .

[0076] In the oil pump bracket assembly of the third embodiment, the lower part of the oil pump controller can sink into the groove 11 and the installation pipe 12 on the flange 10, which reduces the characteristic height of the oil pump controller on the flange surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com