Cultivation system

A cultivation container and culture medium technology, applied in the field of cultivation system, can solve the problems of light irradiation quality deviation, high cost, etc., achieve the effect of improving precision, reducing pressure, and realizing quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

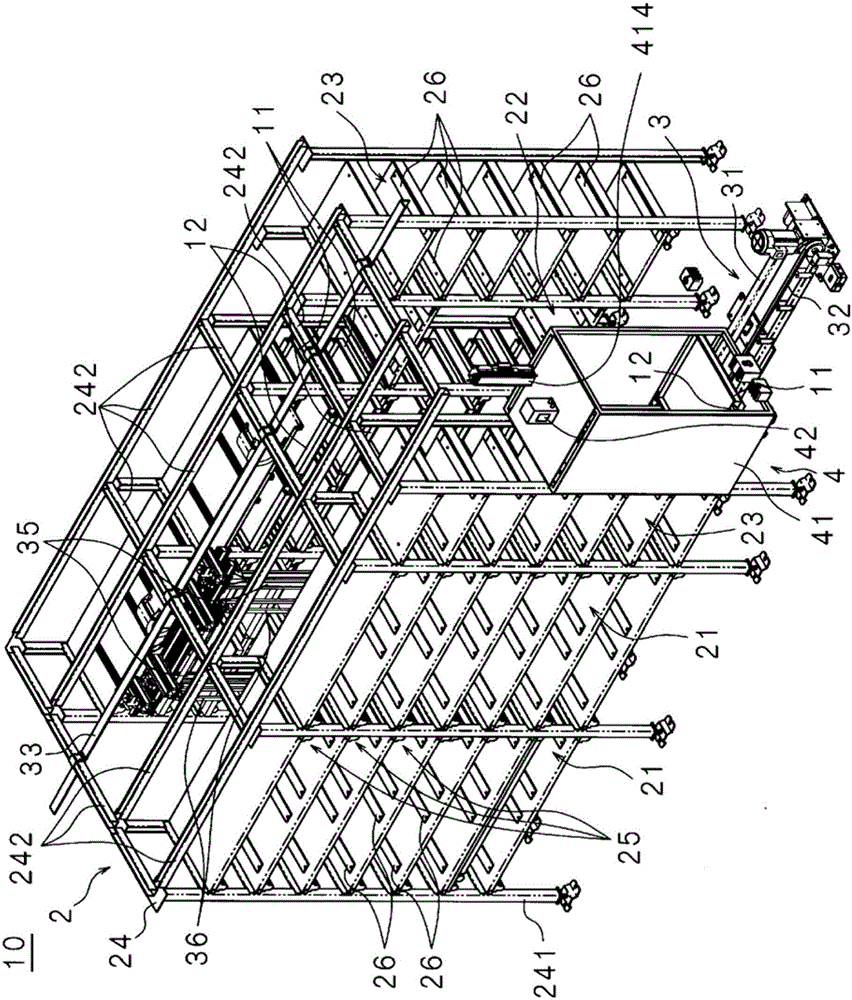

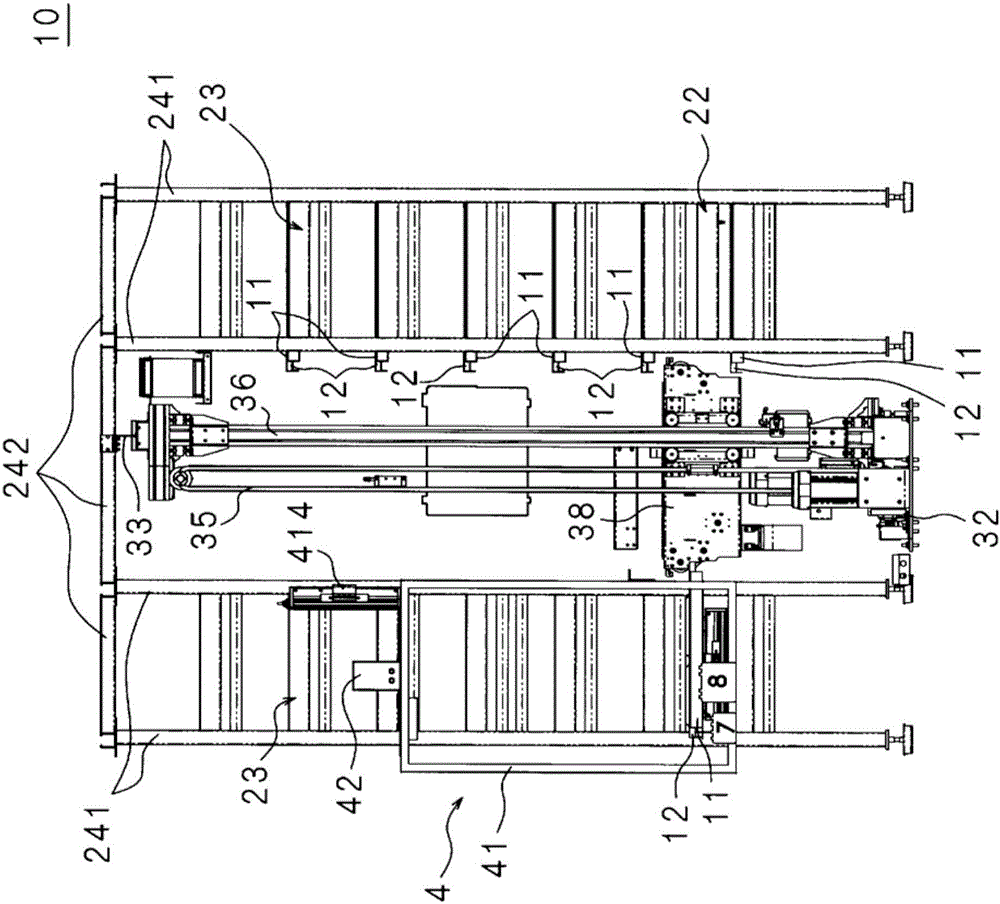

[0049] The cultivation system according to Embodiment 1 shown below is used in the greening process among the processes of sowing, germination, greening, seedling selection, seedling raising, seedling transplanting, cultivation, and harvesting in a plant factory. The greening process is a step of leaving the sown container in a dark room for 2 days to germinate, then leaving the container in a greening room for 4 days, and irradiating the sprouts with light in the greening room to make greening.

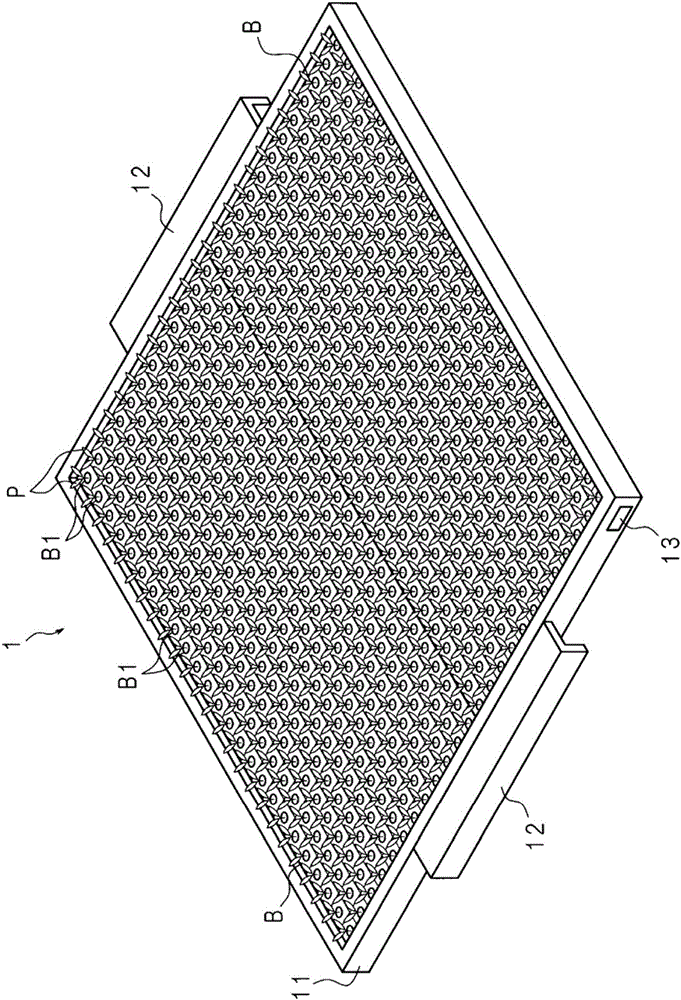

[0050] First, the cultivation unit for housing the seedlings of the plants P will be described. figure 1 It is a perspective view which shows an example of the cultivation unit 1 which accommodates the plant P of Embodiment 1. As shown in FIG. The cultivation unit 1 includes: a plant P; a medium B for cultivating the plant P; and two sets of cultivation trays 11 that accommodate the plant P and the medium B in parallel.

[0051] The cultivation tray 11 is a rectangular dish made of ...

Embodiment approach 2

[0120] In Embodiment 2, the structure which performs seedling selection collectively by the cultivation apparatus 10 on the last day of a greening process is employ|adopted.

[0121] The structure of the cultivation system of Embodiment 2 is the same as that of the system of Embodiment 1 except for the structure of the transplanting part related to seedling selection described below, and therefore, the detailed description will be omitted with the same reference numerals for common structures.

[0122] Figure 11 It is a perspective view which shows an example of the cultivation tray 8 used for seedling selection in Embodiment 2. The cultivation tray 8 is made of, for example, expanded styrene and has a flat plate shape, and has holes 81 arranged in multiple rows in each of the vertical and horizontal directions. Each hole 81 is comprised so that the seedbed part which cut|disconnected the culture medium B can be accommodated without gap. Specifically, each of the holes 81 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com