Ship with fuel tank for liquefied gas

A liquid gas and fuel tank technology, which is used in cargo, ship construction, ship propulsion, etc., to achieve the effect of reducing the danger zone and area, reliable layout, and easy replaceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The same reference numbers used below in the figures each refer to the same ship area or ship equipment.

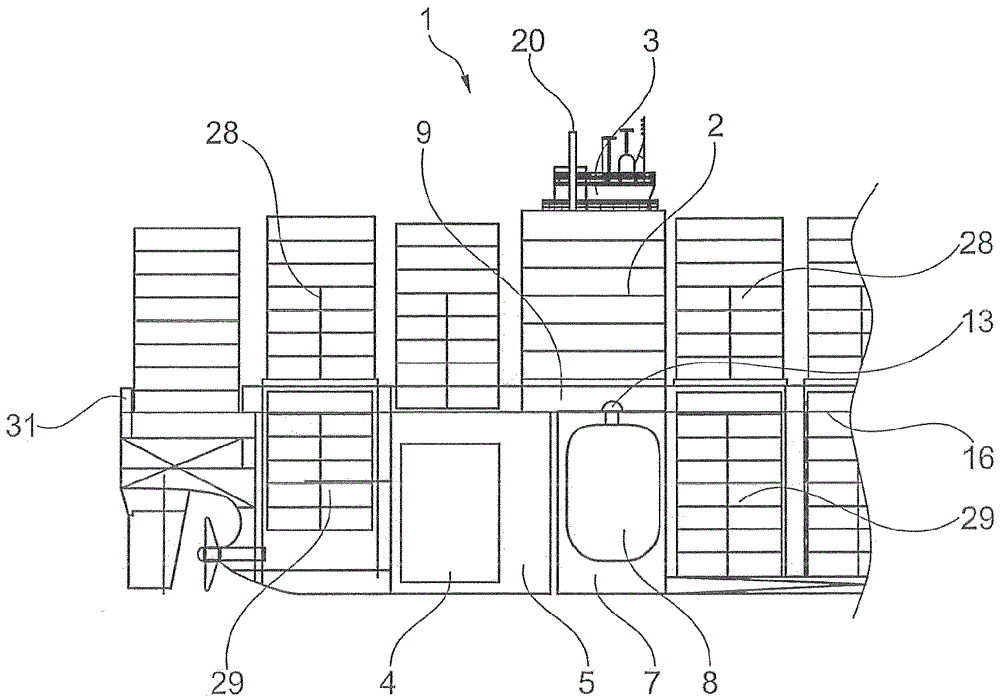

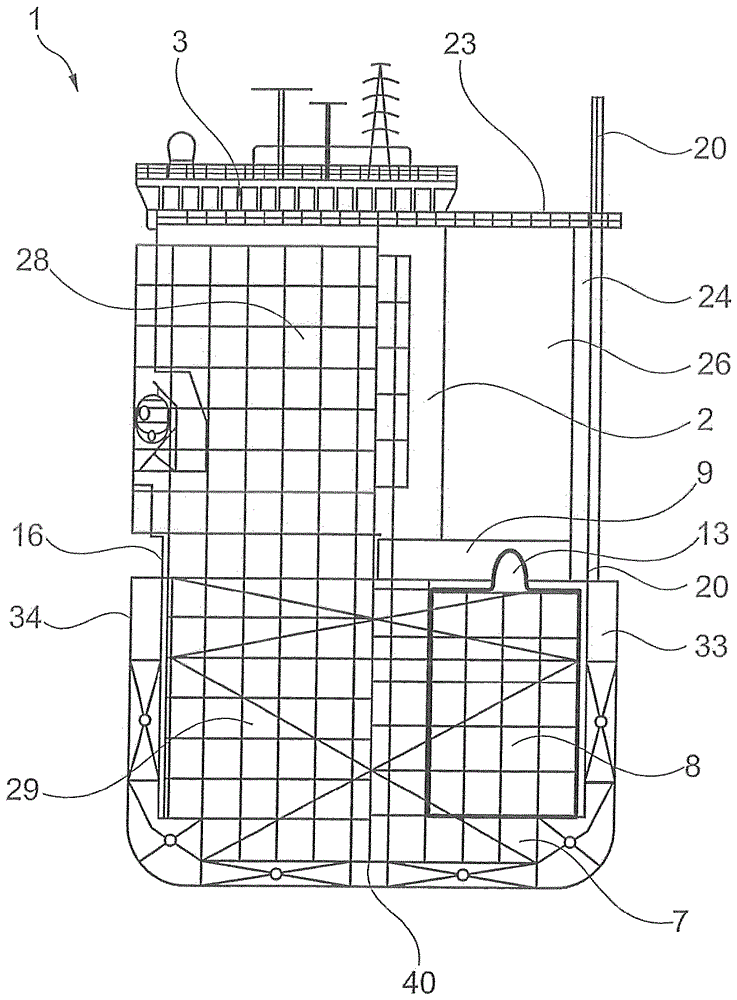

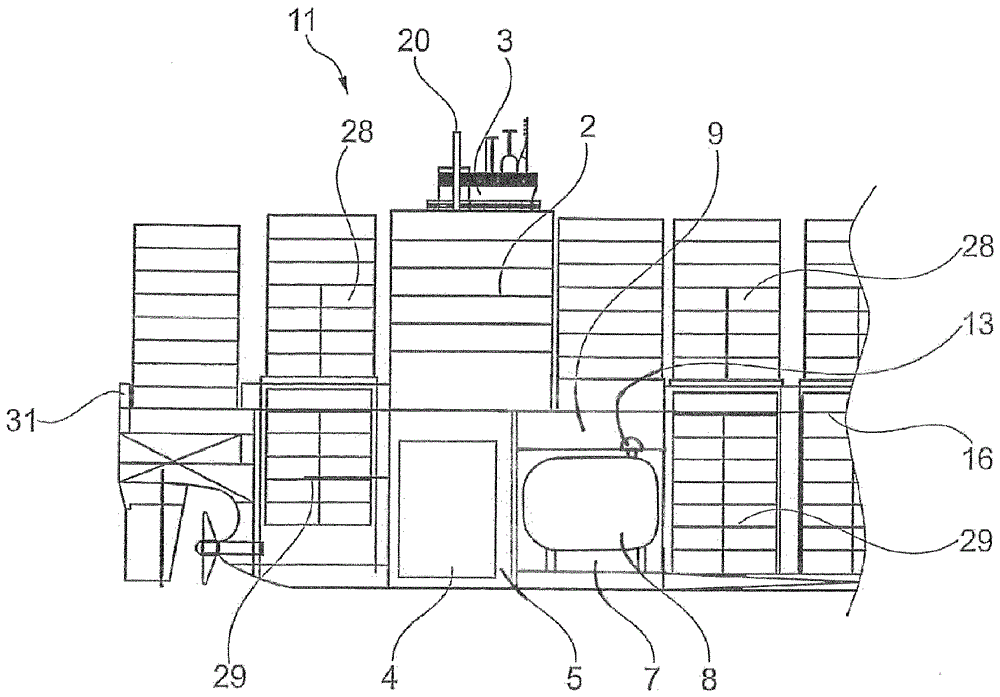

[0050] according to figure 1 The illustration in a schematic longitudinal section through the region of the ship 1 , in particular the stern of the container ship, shows the gas service compartment 9 below the deckhouse 2 approximately at the main deck 16 in the area and has the length of the deckhouse 2.

[0051] Below the gaseous operating compartment 9 there is a fuel compartment 7 in which a fuel tank 8 for liquid gas is arranged. The approximately cylindrical box 8 in cross section is designed as a C box. This means that the tank 8 is, for example, a prefabricated tank on land, which is then placed in the fuel tank 7 fixedly hung between two transverse bulkheads of the ship 1 . The suitably double-walled tank 8 protrudes here with its dome 13 , which has the necessary connections to the tank and the liquid gas contained therein, into the gas operating compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com