Cathode for preventing corrosion, and concrete structure corrosion prevention structure and corrosion prevention method employing same

A concrete structure, anti-corrosion technology, applied in the direction of basic structure engineering, chemical instruments and methods, hydraulic material layered products, etc., to achieve the effect of uniform potential distribution and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0198] Hereinafter, the present invention will be specifically described using examples.

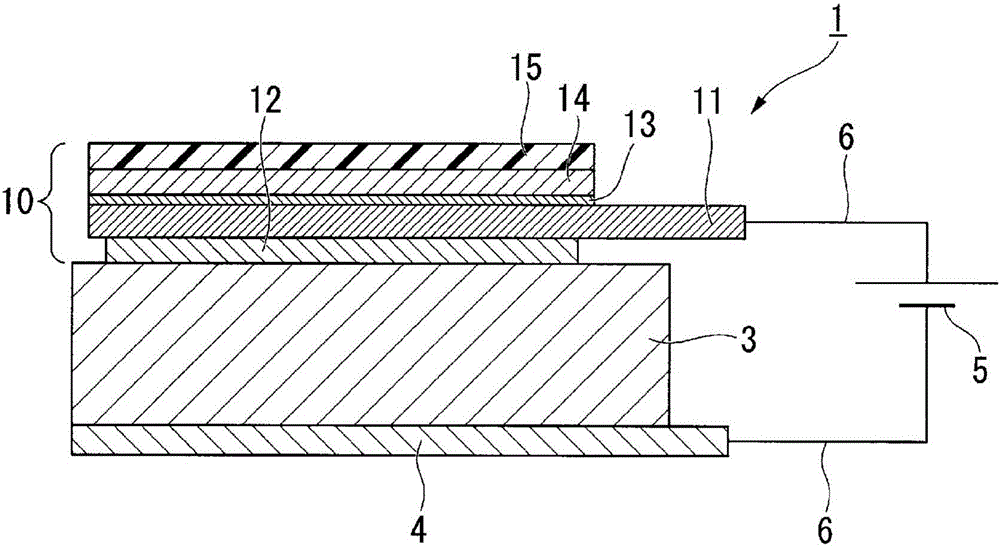

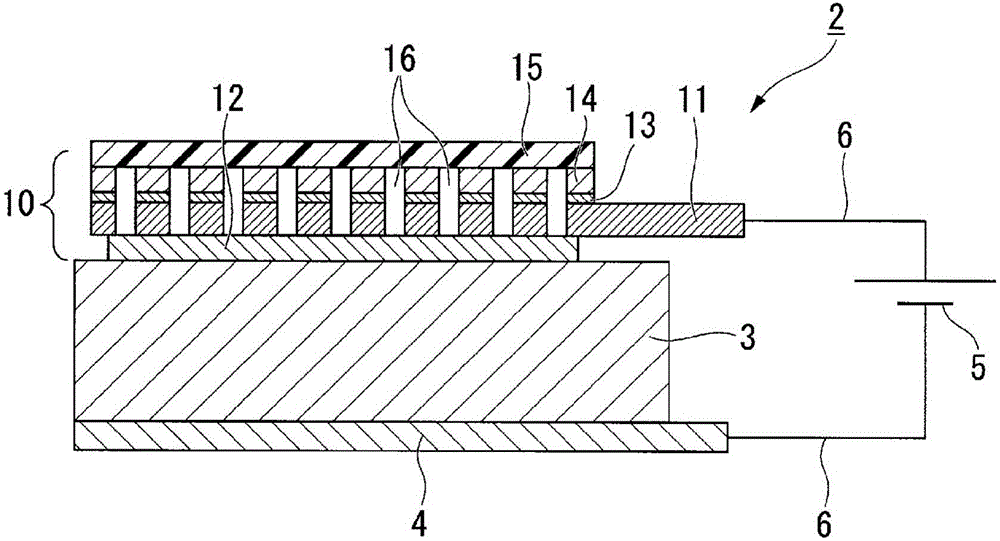

[0199] The anticorrosion anode 10 of Example 1 was produced in the following procedure.

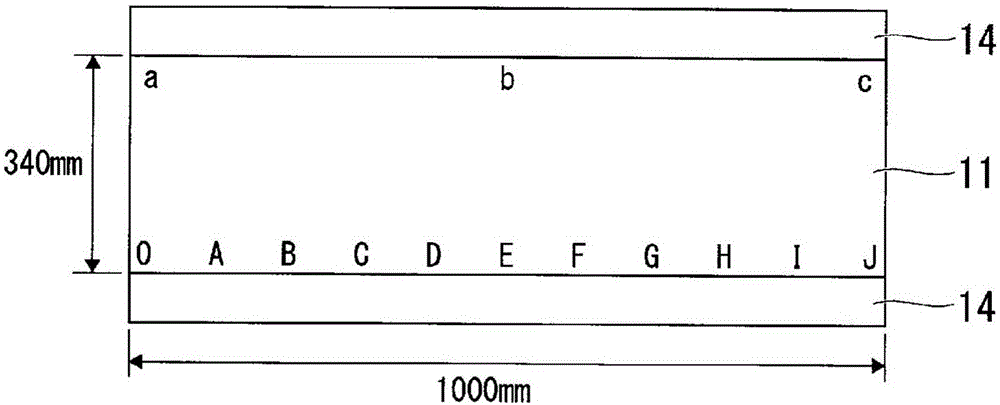

[0200] With dry lamination, the thickness is about 0.25 ~ 0.3mm, and the mass per unit area is 50g / m 2 A reinforcement layer 14 made of PP nonwoven fabric with a width of 460 mm and a length of 1000 mm is laminated on a conductive layer 11 made of a graphite sheet made by an expansion method with a thickness of 0.125 mm, a width of 340 mm, and a length of 1000 mm.

[0201] The obtained laminated body of the conductive layer 11 and the reinforcement layer 14 was punched from the side of the conductive layer 11 with a hot needle to form a plurality of through-holes 16 in the conductive layer 11 and the reinforcement layer 14 .

[0202] A polyvinyl fluoride film with a thickness of 40 μm and a width of 460 mm was dry-laminated on the surface of the conductive layer 11 on which the reinforcement layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact resistance | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com