Improved electrostatic transducer

A transducer, electrostatic technology, used in semiconductor electrostatic transducers, electrostatic transducer speakers, electrostatic transducer microphones, etc., to increase the available frequency range, good acoustic performance, and improve overall quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

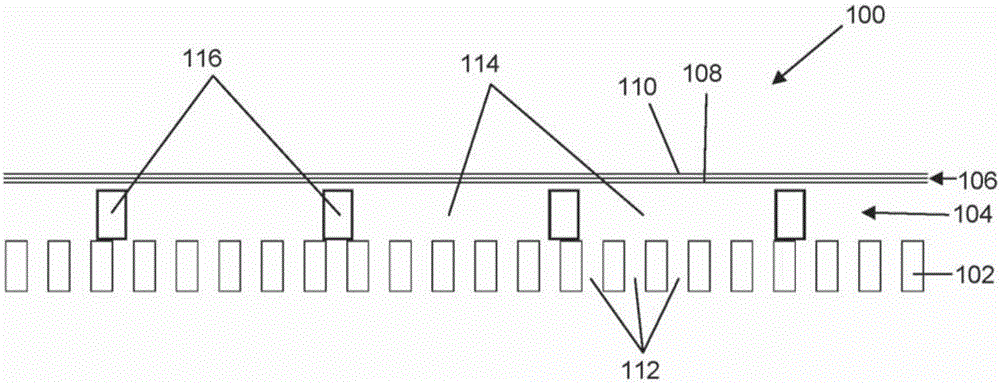

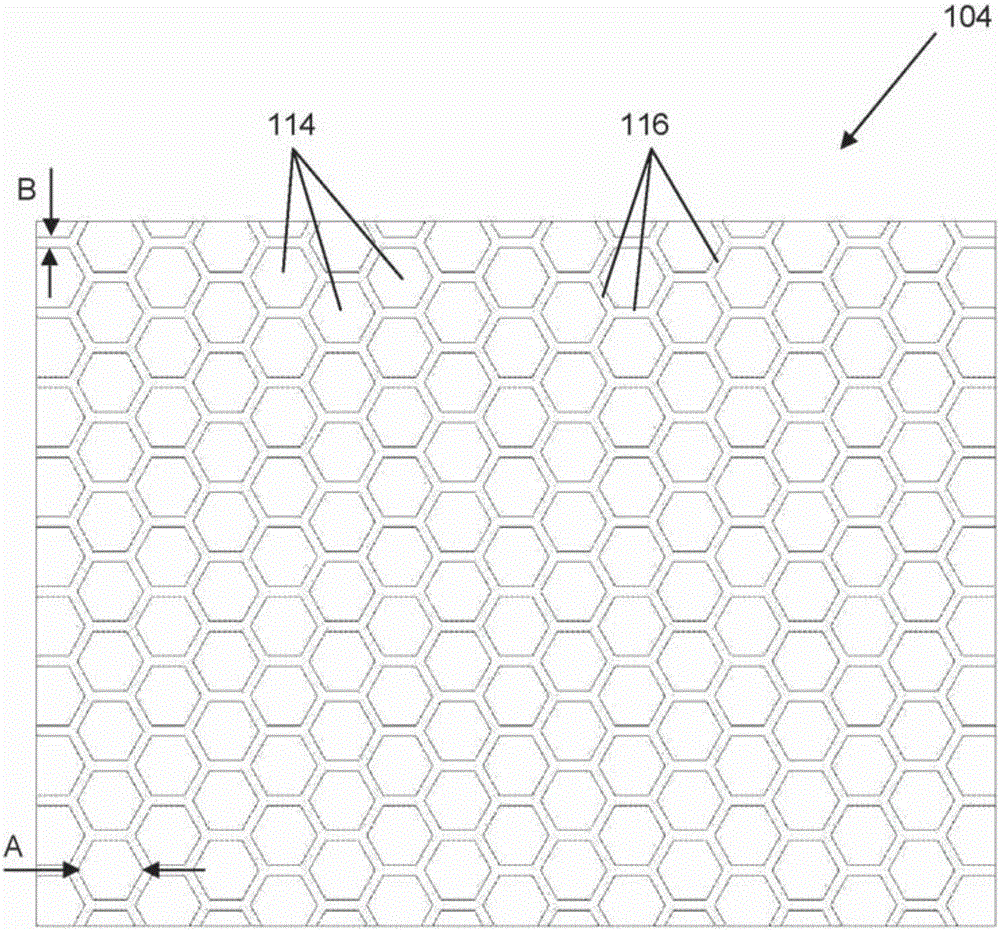

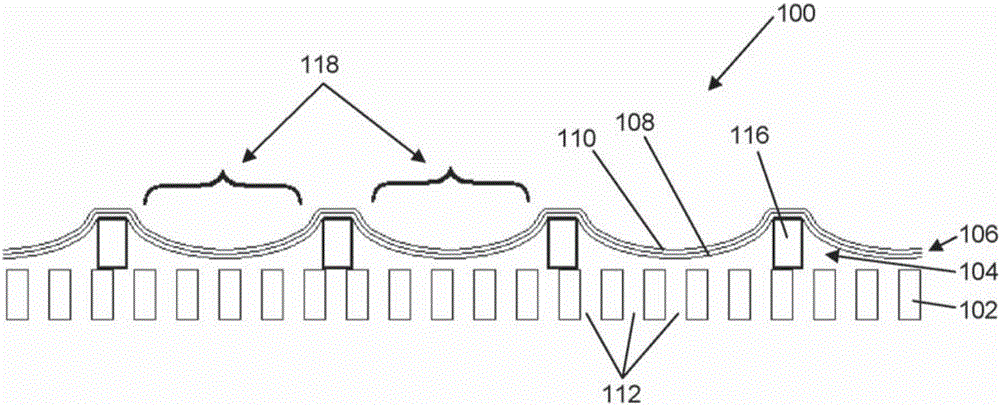

[0048] figure 1 A transducer 100 is shown comprising a backplate member 102, which is 1 mm in thickness. The back plate member 102 is made from aluminum sheet, although other materials or combinations of materials may also be used. The insulating spacer member 104 is provided on the back plate member. The spacer member 104 has a thickness of 0.3 mm and is made of polymer Mylar.

[0049] The composite membrane 106 is disposed on the spacer member 104 . The membrane 106 comprises a 10 μm thick polymer sheet with an aluminum layer 110 disposed thereon by metallization. In this embodiment, the aluminum layer is provided on the surface of the polymer sheet 108 facing away from the spacer member 104 . However, in other embodiments, the film may include a conductive layer on the side of the polymer layer facing the spacer member, or the conductive layer may be sandwiched between two polymer sheets. In some embodiments, there may be a single flexible conductive layer instead of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com