High-voltage cable connector with temperature measurement function

A high-voltage cable and temperature measurement function technology, applied in the field of cables, can solve the problems of terminal abnormality, error fluctuating with seasons, and not being widely used, so as to improve the temperature measurement accuracy and ensure safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

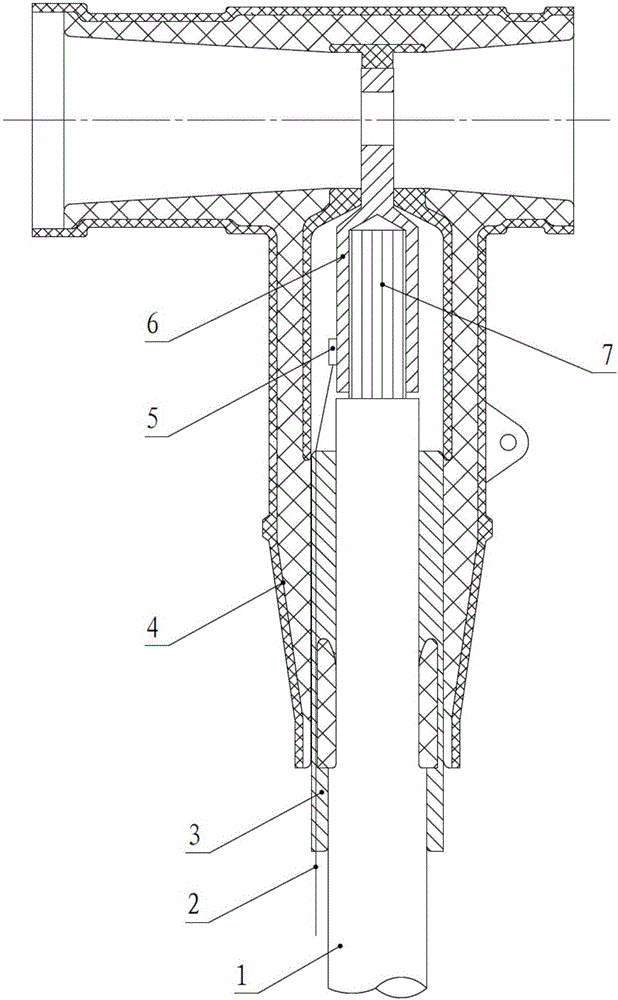

[0015] The present invention will be further described below in conjunction with accompanying drawing.

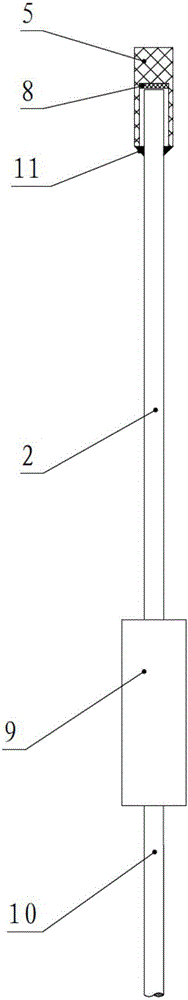

[0016] see figure 1 and figure 2 , The present invention includes a temperature measuring optical fiber 2, a stress cone 3, a terminal sheath 4, a heat-conducting ceramic contact 5, a connecting terminal 6, a photosensitive coating 8, a photoelectric converter 9, a shielding wire 10 and a sealant 11.

[0017] The optical fiber channel (fiber hole) is reserved in the stress cone 3 of the plug-in head, and the temperature-measuring optical fiber 2 passes through the stress cone 3 to reach the terminal 6 inside the plug-in head (configured in the factory). The head of the temperature-measuring optical fiber 2 has a heat-conducting ceramic contact 5, and the heat-conducting ceramic contact 5 is placed on the crimping part of the terminal 6 (the connection between the terminal 6 and the cable core 7) and fixed. The temperature-measuring optical fiber 2 directly obtains temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com