Micro-water content fiber laser detector based on secondary modulation and data stitching technology

A micro-water content, fiber laser technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of reducing the insulation performance and safety of equipment, difficult to cover gas absorption peaks by current scanning, and easy to be susceptible to electromagnetic interference. Effects of detection, increased scanning range and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

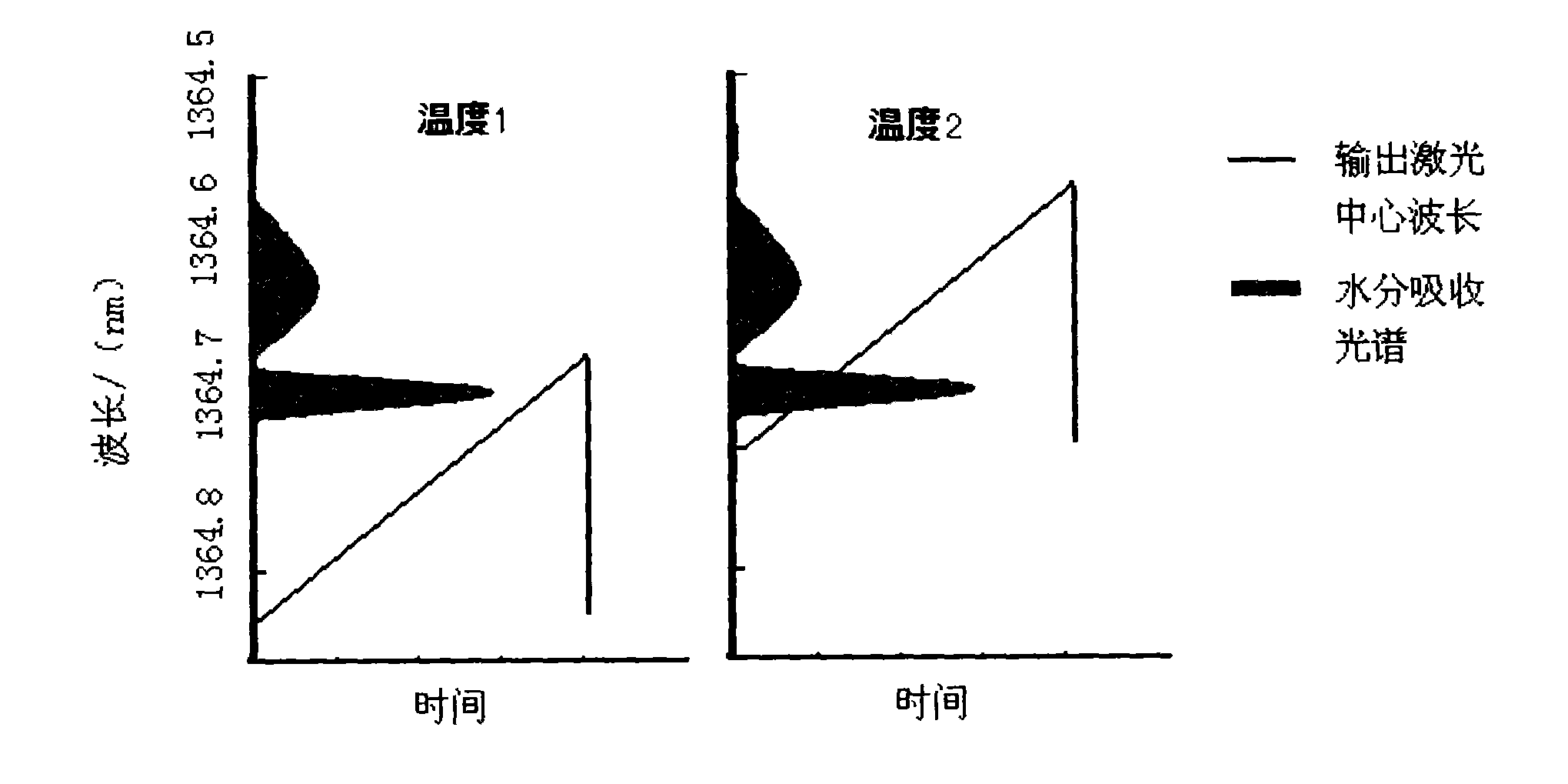

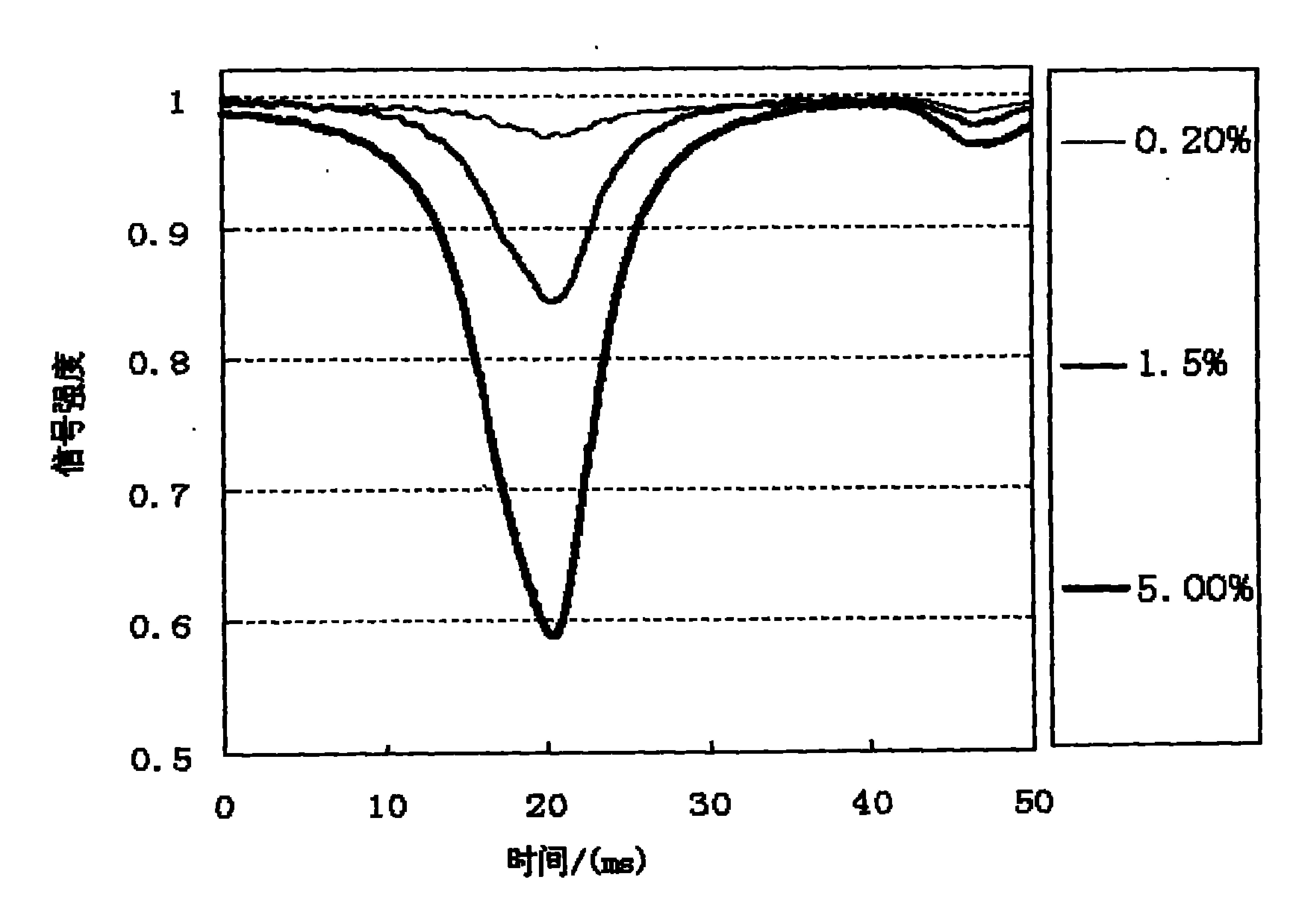

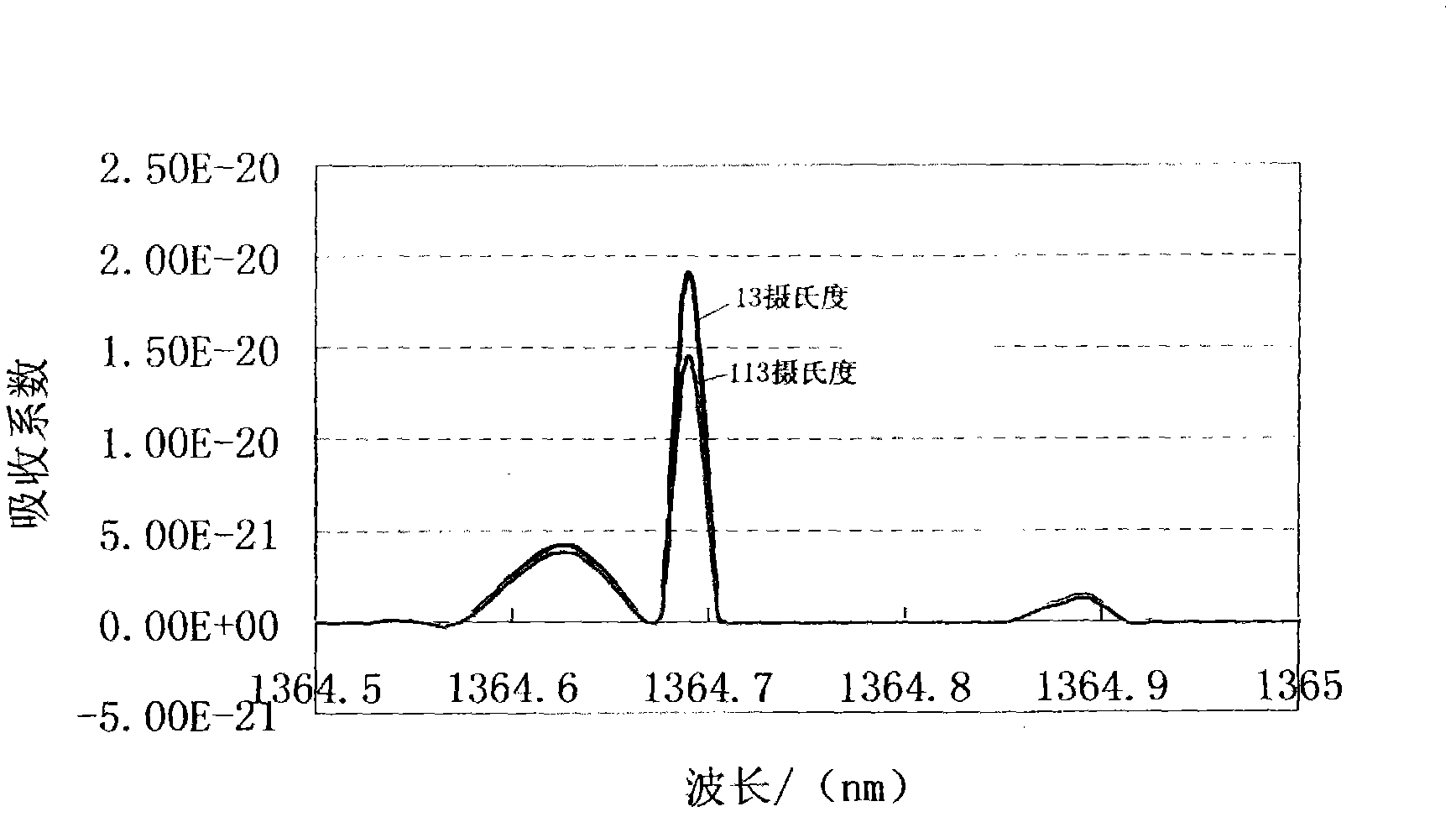

[0026] The present invention will be further described below with reference to the accompanying drawings.

[0027] like figure 1 As shown, a fiber laser detector for micro-water content based on secondary modulation and data stitching technology includes a single-chip microcomputer 7 connected in sequence, a laser 4 that receives the control of the single-chip computer 7 to emit laser light, and a second laser that divides the laser light of the laser 4 into two paths. A fiber coupler 3 and a probe 1 for receiving one laser of the first fiber coupler 3, the first fiber coupler 3 is connected with another laser that receives the first fiber coupler 3 and divides the other laser into two paths The second fiber coupler 11, the second fiber coupler 11 is connected with a first photodetector 6 that receives a channel of laser light from the second fiber coupler 11 and converts the channel of laser light into an electrical signal. The signal output end is connected to the single-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com