Sweet tea and preparation method thereof

A technology of sweet tea and greening, applied in the field of sweet tea and its preparation, can solve the problems of poor taste, achieve the effect of bright yellow-green soup, reduce bitterness and astringency, and increase content content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

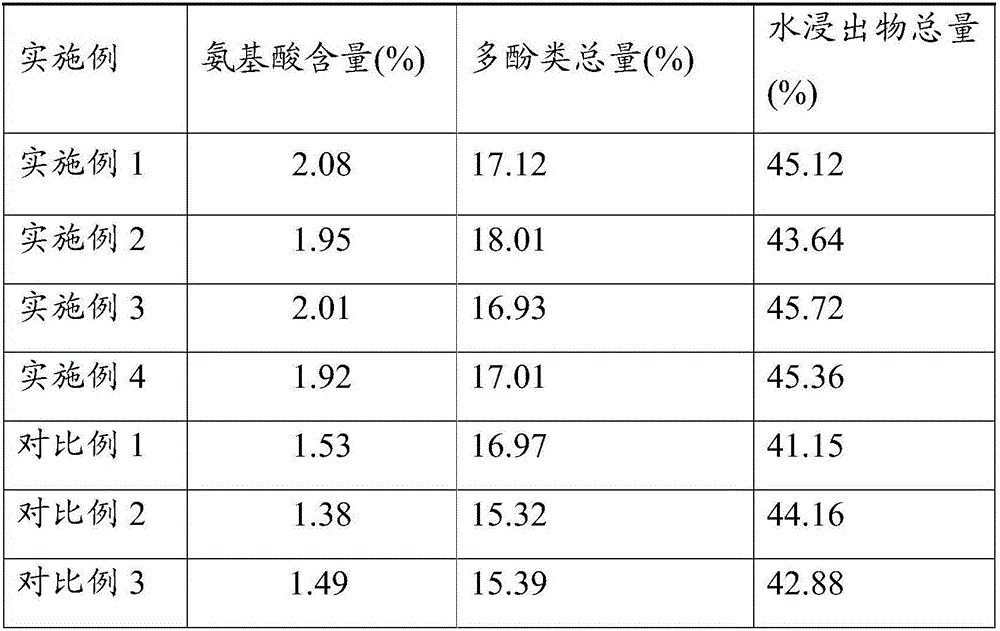

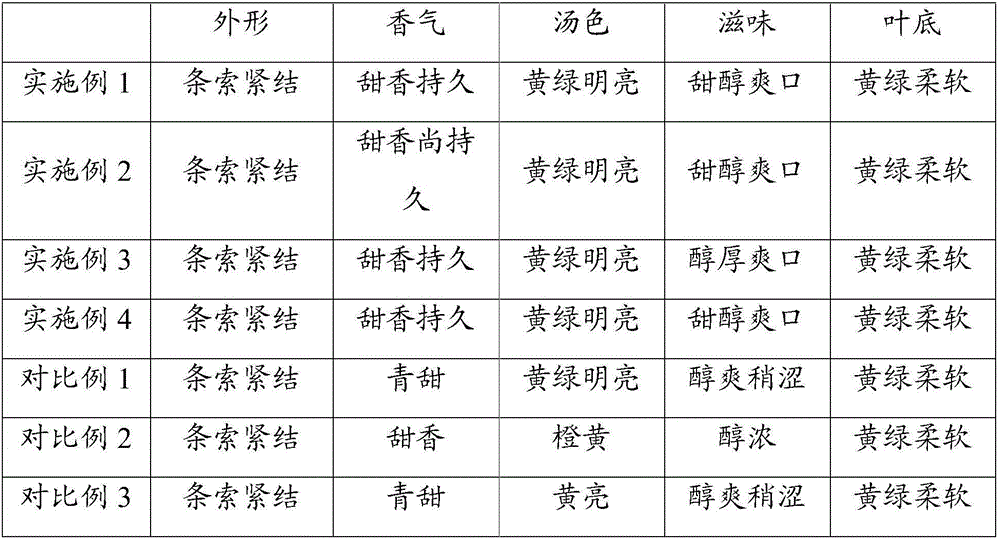

Examples

Embodiment 1

[0023] A preparation method of sweet tea, comprising the following steps:

[0024] (1) Collect sweet tea fresh leaves;

[0025] (2) Spread the fresh leaves of sweet tea for 30 minutes to get the leaves, the temperature of which is 28-32°C, the relative humidity of 80-90%, and the thickness of 3-5cm;

[0026] (3) Put the spread leaves at a temperature of 200-220° C. for 4 minutes to obtain green leaves;

[0027] (4) Knead the green leaves: take the leaves to the upper edge of the flat kneading barrel as the standard, and press the leaves flat and slightly; first empty knead (even if the kneading cover is slightly connected to the green leaves, no pressure is applied) for 5 minutes, lightly press (that is, rotate the control Knead the hand wheel for lifting and lowering the cover, so that the green leaves are lightly squeezed) for 1 minute, and then press the medium pressure (that is, turn the hand wheel to make the kneading cover drop to half of the scale, or a slight foam app...

Embodiment 2

[0031] A preparation method of sweet tea, comprising the following steps:

[0032] (1) Collect sweet tea fresh leaves;

[0033] (2) Spread the fresh leaves of sweet tea for 20 minutes to get the leaves, the temperature of which is 28-32°C, the relative humidity of 80-90%, and the thickness of 3-5cm;

[0034] (3) The green leaves are obtained by curing the spread leaves at a temperature of 200-220°C for 3 minutes;

[0035] (4) Knead the green leaves: take the leaves to the upper edge of the flat kneading barrel as the standard, and press the leaves flat and slightly; first empty knead (even if the kneading cover is slightly connected to the green leaves, no pressure is applied) for 5 minutes, lightly press (that is, rotate the control Knead the hand wheel for lifting and lowering the cover, so that the green leaves are lightly squeezed) for 1 minute, and then press the medium pressure (that is, turn the hand wheel to make the kneading cover drop to half of the scale, or a slig...

Embodiment 3

[0039] A preparation method of sweet tea, comprising the following steps:

[0040] (1) Collect sweet tea fresh leaves;

[0041] (2) Spread the fresh leaves of sweet tea for 40 minutes to get the leaves, the temperature of which is 28-32°C, the relative humidity of 80-90%, and the thickness of 3-5cm;

[0042] (3) Put the spread leaves at a temperature of 200-220° C. for 5 minutes to obtain green leaves;

[0043] (4) Knead the green leaves: take the leaves to the upper edge of the flat kneading barrel as the standard, and press the leaves flat and slightly; first empty knead (even if the kneading cover is slightly connected to the green leaves, no pressure is applied) for 5 minutes, lightly press (that is, rotate the control Knead the hand wheel for lifting and lowering the cover, so that the green leaves are lightly squeezed) for 1 minute, and then press the medium pressure (that is, turn the hand wheel to make the kneading cover drop to half of the scale, or a slight foam app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com