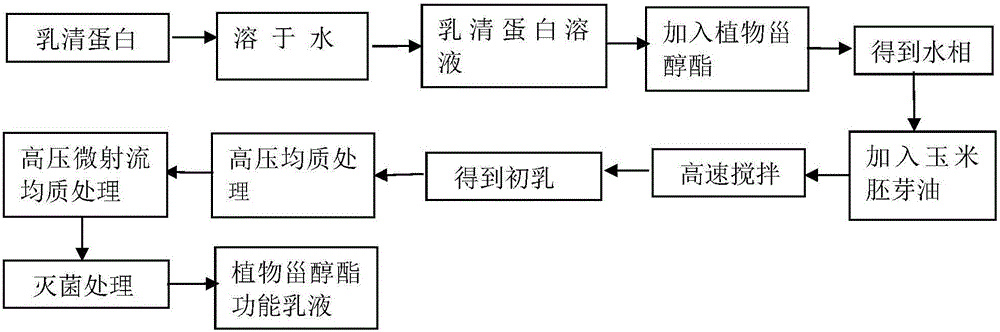

Preparation method of functional phytosteryl ester emulsion

A technology of phytosterol ester and emulsion, which is applied in the field of food processing, can solve the problems of low bioavailability, inability to widely use food, and single nutritional components, and achieve the effects of simple preparation method, enhancing immunity, and inhibiting tumors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

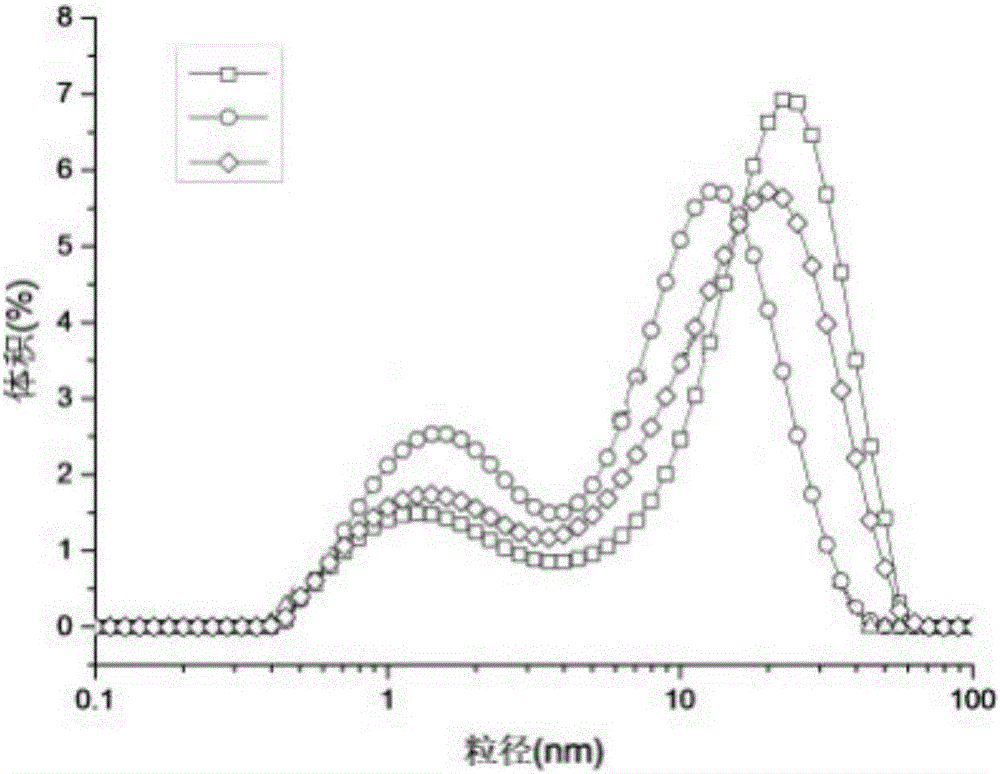

[0033] Mix whey protein with water to make a 3% protein solution, then add β-sitosterol ester according to the ratio of 1:2 whey protein solution: β-sitosterol ester and stir to completely dissolve to obtain the water phase; mix the above solution Add to the corn germ oil phase. The above-mentioned mixed solution is stirred at a high speed, the above-mentioned stirring speed is 11000r / min, and the stirring time is 20min, and the colostrum is formed after high-speed stirring; the colostrum is heat-treated at 60°C for 15min, and then subjected to high-pressure homogenization treatment, the above-mentioned homogeneous The pressure is 20MPa, the homogenization time is 10min, and then undergoes high-pressure micro-jet homogenization treatment. The above-mentioned micro-jet homogenization pressure is 120MPa, the micro-jet homogenization time is 3min, and the emulsion obtained after micro-jet homogenization is sterilized. Phytosterol ester functional emulsion. The average particle s...

Embodiment 2

[0035] Mix whey protein with water to make a 4% protein solution, then add stigmasteryl ester according to the ratio of whey protein solution: stigmasteryl ester 1:3 and stir to completely dissolve to obtain the water phase; add the above solution to corn germ in the oil phase. The above-mentioned mixed solution is stirred at a high speed, the above-mentioned stirring speed is 11000r / min, and the stirring time is 20min. After high-speed stirring, colostrum is formed; the colostrum is heat-treated at 55°C for 20min, and then subjected to high-pressure homogenization treatment. The pressure is 25MPa, the homogenization time is 8 minutes, and then undergoes high-pressure micro-jet homogenization treatment. The above-mentioned micro-jet homogenization pressure is 100 MPa, the micro-jet homogenization time is 4 minutes, and the emulsion obtained after micro-jet homogenization is sterilized. Phytosterol ester functional emulsion. The average particle size of the functional emulsion...

Embodiment 3

[0037]Mix whey protein with water to make a 5% protein solution, then add campesterol ester according to the ratio of 1:4 whey protein solution: campesterol ester and stir to completely dissolve to obtain the water phase; add the above solution to corn germ in the oil phase. The above-mentioned mixed solution is stirred at a high speed, the above-mentioned stirring speed is 11000r / min, and the stirring time is 20min. After high-speed stirring, colostrum is formed; the colostrum is heat-treated at 50°C for 25min, and then subjected to high-pressure homogenization treatment, the above-mentioned homogeneous The pressure is 30MPa, the homogenization time is 5min, and then subjected to high-pressure micro-jet homogenization treatment, the above-mentioned micro-jet homogenization pressure is 80MPa, the micro-jet homogenization time is 5min, and the emulsion obtained after micro-jet homogenization is sterilized. Phytosterol ester functional emulsion. The average particle size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com