Cutting-fluid preparing device and applying method

A cutting fluid and mixing device technology, applied in mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve problems such as affecting the use of machine tools, waste of raw liquid, and untimely manual deployment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

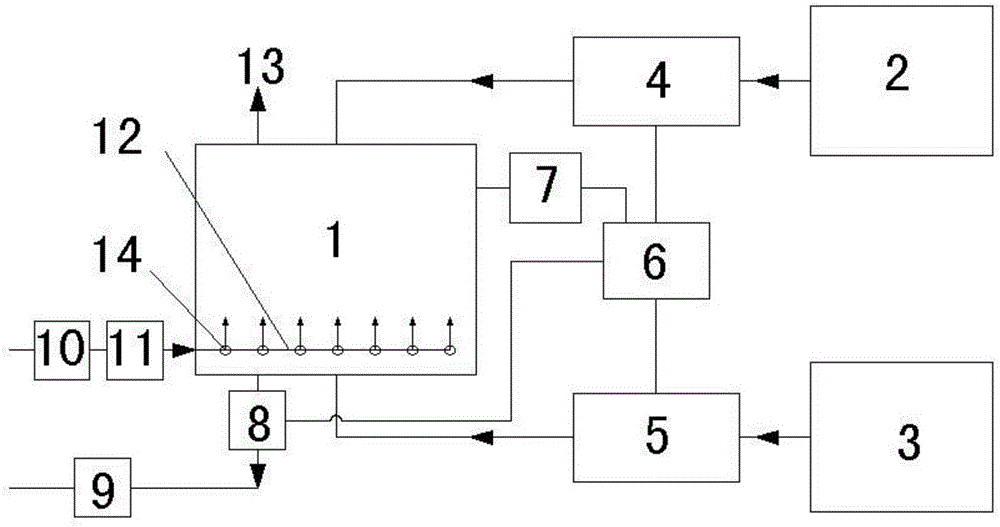

[0023] The stock solution is stored in the first storage device 2, and the diluent is stored in the second storage device 3. The control system 6 drives the first extraction device 4 and the second extraction device 5 respectively, and the first extraction device 4 extracts the liquid in the first storage device 2. The raw liquid is sent to the mixing device 1, the second extraction device 5 sends the diluent in the second storage device 3 to the mixing device 1, the gas inlet 10 sends the compressed air to the shunt pipe 12 through the one-way valve 11, and the compressed air passes through the shunt The air hole 14 on the pipe 12 enters the mixing device 1, and the compressed air moves from bottom to top in the mixing device 1. The stock solution and the diluent are mixed evenly under the stirring action of the compressed air. When the gas at the top of the mixing device reaches the set pressure, the gas Exhausted from the constant pressure exhaust valve 13, the control syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com