Rolling barrel for rolling type granulator

A technology of a granulator and a roller press, which is applied in the field of roller press, can solve problems such as unfavorable continuous use of the granulator and blockage of the granulation tank, and achieve the effects of ensuring popularization, preventing blockage and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

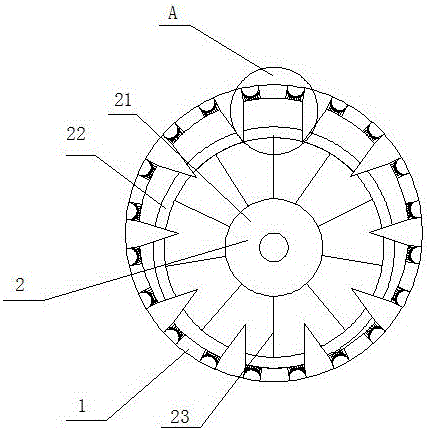

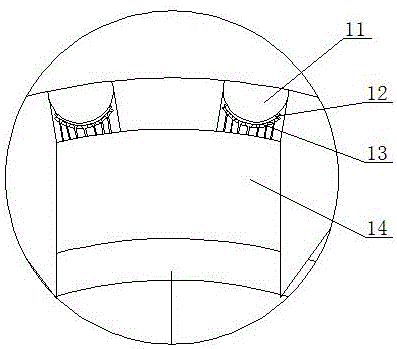

[0034] Such as figure 1 , 2 As shown, the roller press cylinder of the roller press granulator of the present invention comprises cylinder body 1, and the outer surface of cylinder body 1 is provided with granulation tank 11, is provided with elastic portion 12 on the bottom of granulation tank 11, and elastic portion The lower side of 12 has a buffer chamber 13, the buffer chamber 13 communicates with the pressurization chamber 14 and is sealed and isolated from the outside of the cylinder 1, the pressurization of the pressurization chamber 14 can make the elastic part 12 squeeze the granulation tank 11. This structure achieves anti-clogging by extruding the granulation tank 11, and there is no through hole in the granulation tank 11, which effectively prevents the blockage of the through hole in the granulation tank 11. This structure can effectively use the elastic part 12 to push, thereby It is convenient to realize the cleaning of the clogged granulation tank 11, so as t...

Embodiment 2

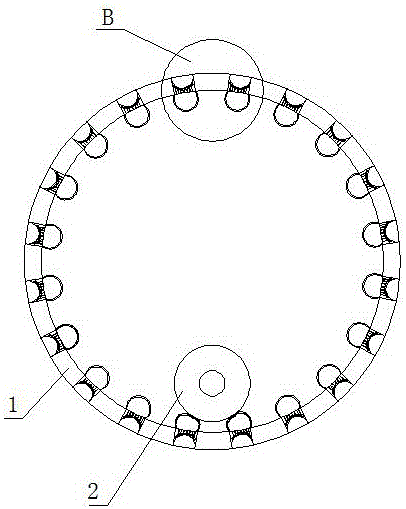

[0040] Such as image 3 , 4 As shown, the roller press cylinder of the roller press granulator of the present invention comprises cylinder body 1, and the outer surface of cylinder body 1 is provided with granulation tank 11, is provided with elastic portion 12 on the bottom of granulation tank 11, and elastic portion The lower side of 12 has a buffer chamber 13, the buffer chamber 13 communicates with the pressurization chamber 14 and is sealed and isolated from the outside of the cylinder 1, the pressurization of the pressurization chamber 14 can make the elastic part 12 squeeze the granulation tank 11.

[0041] The side walls of the buffer cavity 13 have protrusions, which are used to prevent the opposite side walls of the buffer cavity 13 from sticking. Through holes are provided in gaps between adjacent protrusions, and the buffer chamber 13 communicates with the pressurizing chamber 14 through the through holes.

[0042] The cylinder body 1 is hollow and provided with ...

Embodiment 3

[0044] Based on the rolling cylinder of embodiment 1 or 2, its anti-granulation tank 11 blockage method is:

[0045] Step 1: The granulation tank 11 rotates with the cylinder body 1. After the extrusion and granulation of the granulation tank 11 is completed, the pressurization chamber 14 is gradually pressurized, and the elastic part 12 deforms and squeezes the granulation tank 11. At the same time, the elastic part 12 will produce The unshed material particles in the particle trough 11 are pushed out;

[0046] Step 2: After the material particles are pushed out, the piston 22 is gradually moved away from the granulation tank 11 to reduce the pressure in the booster chamber 14 until the pressure in the booster chamber 14 drops to negative pressure with the rotation of the cylinder 1;

[0047] Step 3: After the pressurized chamber 14 is decompressed, the pressure of the assembly is increased. When the pressure is increased to atmospheric pressure, the granulation tank 11 perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com