Lipophilic load type NaHSO4 catalyst as well as preparation method and application thereof

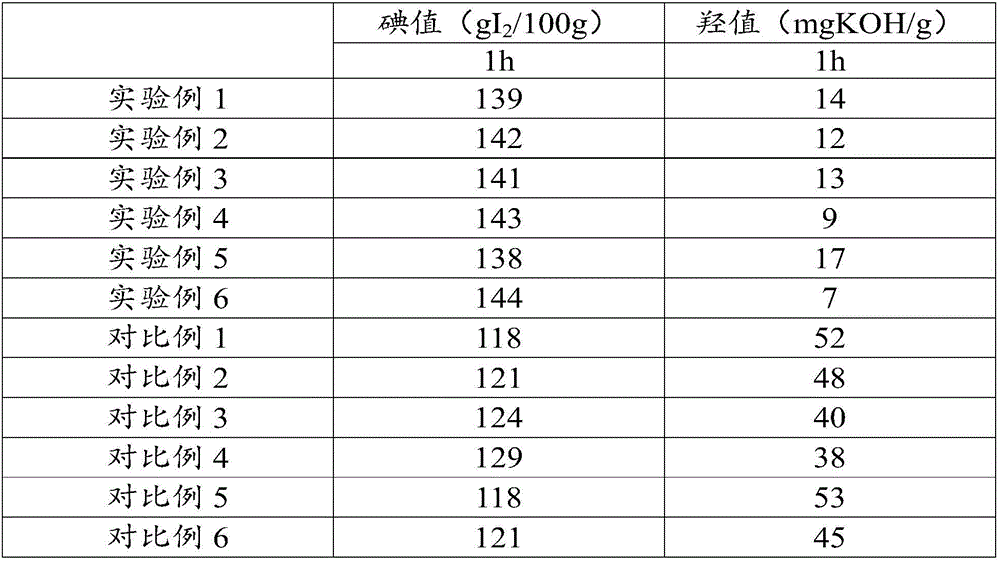

A supported, catalyst technology, applied in the field of catalytic chemistry, can solve the problems of increased catalytic reaction yield and conversion rate, and achieve the effects of improved conversion rate, convenient separation and reuse, and high iodine value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The embodiment of the present invention proposes a lipophilic loaded NaHSO 4 The preparation method of catalyst comprises the following steps:

[0017] Modification step: uniformly mix the carrier material with the alkylsilane solution, filter and dry to obtain the lipophilic carrier material.

[0018] Further, the alkylsilane solution is prepared by mixing the alkylsilane with an organic solvent, wherein the alkylsilane is propyltriethoxysilane, octyltriethoxysilane, methyltriethoxysilane and dodecyltriethoxysilane At least one of the alkyl triethoxysilanes; the organic solvent is any one of toluene and xylene; the used alkyl silanes and organic solvents can be purchased directly from the market.

[0019] Specifically, the carrier material is at least one of MCM-41, MCM-48, MCM-50 and FSM-16. MCM-41, MCM-48, MCM-50 and FSM-16 are all molecular sieves, and can be purchased directly from the market.

[0020] Further, the mixing method of the carrier material and the a...

Embodiment 1

[0032] This embodiment provides a lipophilic NaHSO 4 / MCM-50 catalyst, its preparation steps are as follows:

[0033] Modification step: Add 0.1052g of octyltriethoxysilane to 50mL of xylene, stir and mix evenly, and add 2g of MCM-50 to it, reflux and stir at 150°C for 20h, then suction filter, and wash the filter residue with ethanol solution 2 times, and dried at 90°C for 10 hours to obtain lipophilic MCM-50;

[0034] Loading step: impregnate the above lipophilic MCM-50 in NaHSO 4 In aqueous solution, the NaHSO used 4 The aqueous solution consists of 0.353g NaHSO 4 Dissolved in 4.8mL of water to obtain, ultrasonic treatment for 3h, then separated and dried at 100°C for 8h to obtain lipophilic NaHSO 4 / MCM-50 catalyst.

Embodiment 2

[0036] This embodiment provides a lipophilic NaHSO 4 / MCM-41 catalyst, its preparation steps are as follows:

[0037] Modification step: Add 0.2222g of dodecyltriethoxysilane to 50mL of toluene, stir and mix evenly, and add 2g of MCM-41 to it, reflux and stir at 120°C for 24h, then suction filter, and filter the residue with ethanol solution Washing 3 times and drying at 80°C for 6 hours to obtain lipophilic MCM-41;

[0038] Loading step: impregnate the above lipophilic MCM-41 in NaHSO 4 In aqueous solution, the NaHSO used 4 The aqueous solution consists of 0.5g NaHSO 4 Dissolved in 4.8mL of water to obtain, ultrasonic treatment for 2h, then separated and dried at 120°C for 12h to obtain lipophilic NaHSO 4 / MCM-41 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com