Three-dimensional type arrangement method for hydraulic system equipment of up-pressing type forging set

A hydraulic system, a three-dimensional technology, applied to the driving device of forging presses, presses, manufacturing tools, etc., can solve the problems of long pipelines, increase hydraulic transmission resistance, affect dynamic response, etc., and achieve the elimination of heat dissipation and exhaust devices, The effect of reducing production costs and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

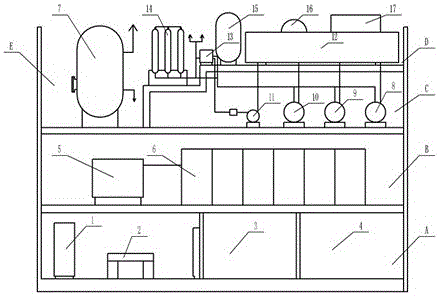

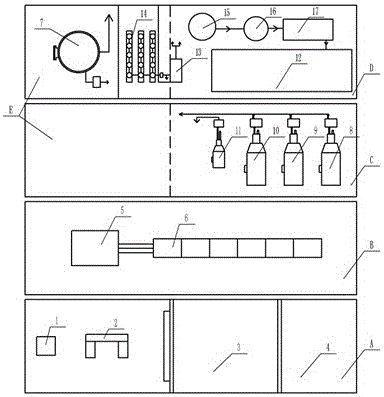

[0012] as attached figure 1 , 2 As shown, first set the equipment foundation into four layers and three or four merged layers, from the bottom upwards: bottom layer A, second layer B, third layer C, fourth layer D, three or four combined layers The hydraulic system equipment in the unit is divided into five parts: the operation control part includes: PLC 1, console 2, management room 3, accessory warehouse 4, the power supply and strong current control equipment part includes: transformer 5, electrical control cabinet 6, hydraulic pressure The pump part includes: main hydraulic pump 8, 9, 10, control pump 11, oil tank and cooling cycle part includes: oil tank 12, hydraulic distributor 13, circulation buffer tank 15, overflow protection filter 16, cooler 17, energy storage The device and hydraulic distributor part include: medium pressure accumulator 7, high pressure accumulator 14. Place PLC1, control panel 2, management room 3, and parts warehouse 4 on the bottom floor, tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com