Rotation-type milling force sensor for measuring torque and axial force

A sensor and milling force technology, applied in measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of poor anti-interference ability and large static linear error, and achieve strong adaptability, stability, High sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings.

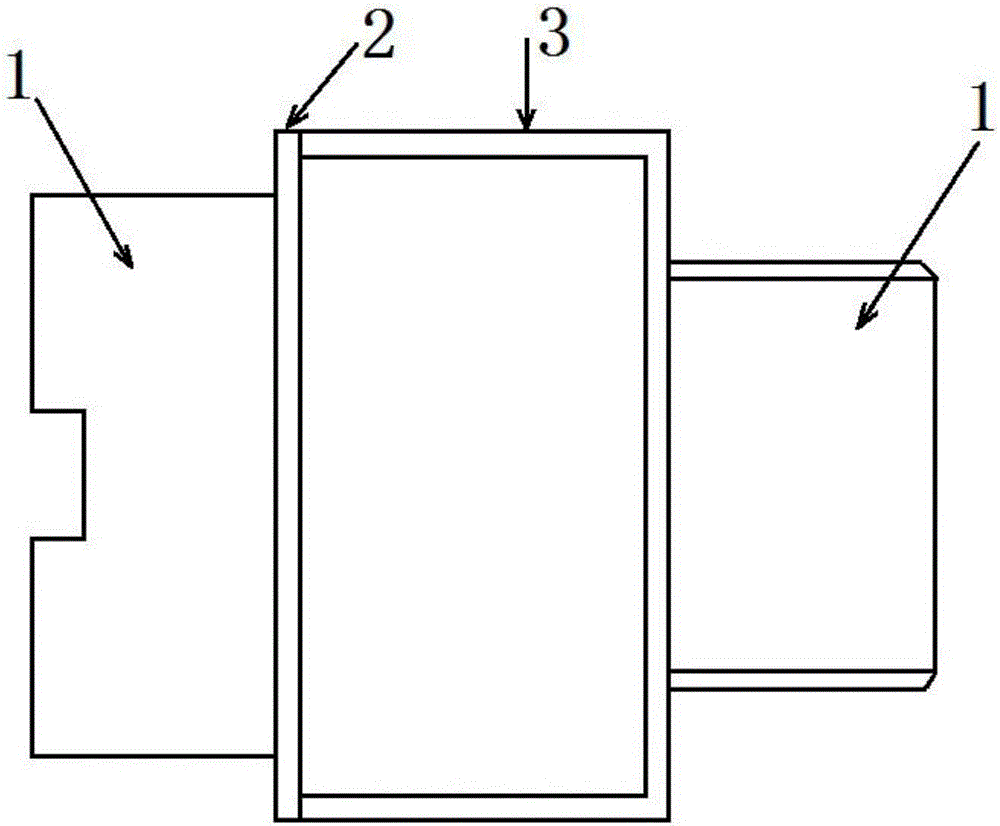

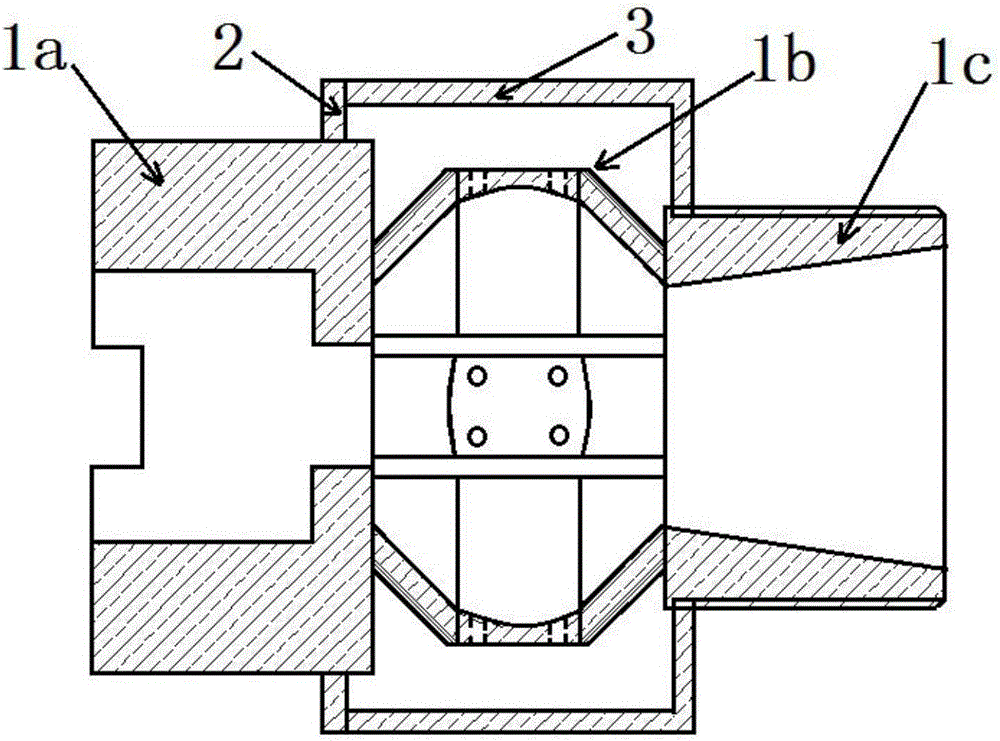

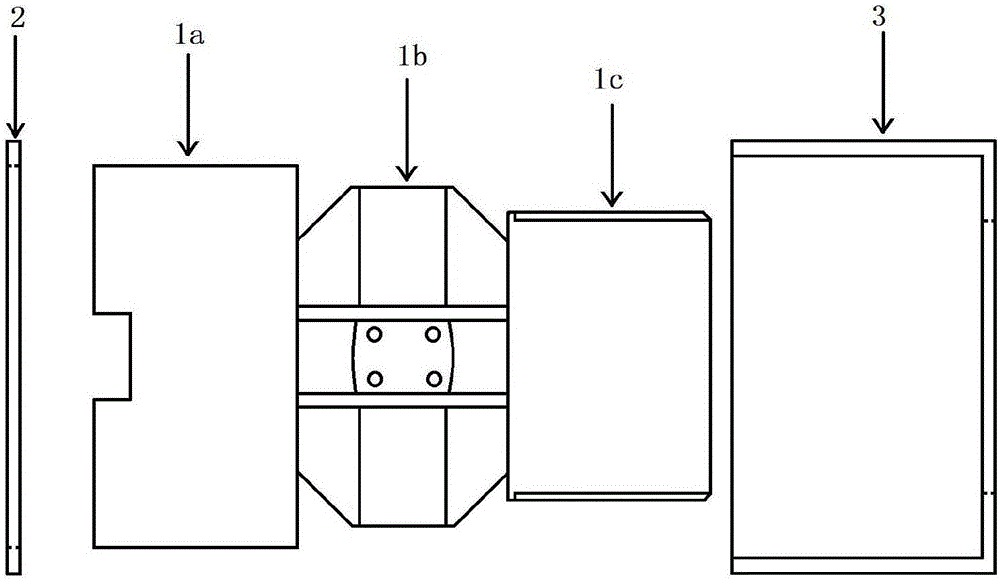

[0024] Reference figure 1 , figure 2 with image 3 , A rotary milling force sensor for measuring torque and axial force, including a main structure 1, a protective shell cover 2 and a protective shell 3. The main structure 1 and the protective shell 3 are connected by threads, and the signal acquisition of the sensor is installed in the protective shell 3. The circuit, the protective shell 3 and the protective shell cover 2 are connected by threads. The main structure 1, the protective shell cover 2 and the protective shell 3 are integrated into one that can be connected to the spindle, install the tool, and monitor the axial milling force and milling torque in real time. Force sensor.

[0025] The protective shell cover 2 is threadedly connected with the protective shell 3 through threaded holes distributed around the periphery to protect the electrical signals in the protective shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com