Manufacturing method of portable solar energy light condensation device

The technology of a concentrating device and manufacturing method, which is applied in the field of solar energy, can solve problems such as the difficulty in improving the conversion efficiency of solar energy, and achieve the effects of strong adhesive strength, non-scratch resistance, increased toughness, and strong sense of integrity and three-dimensionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

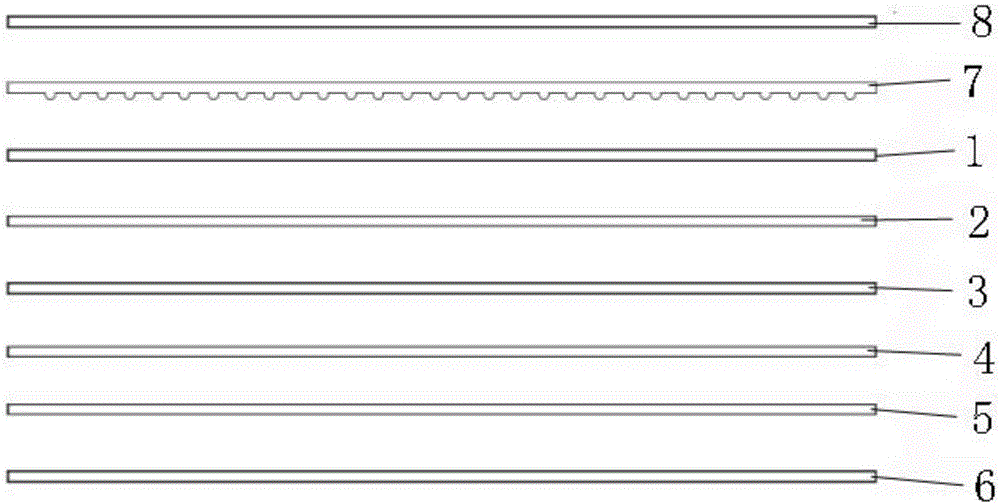

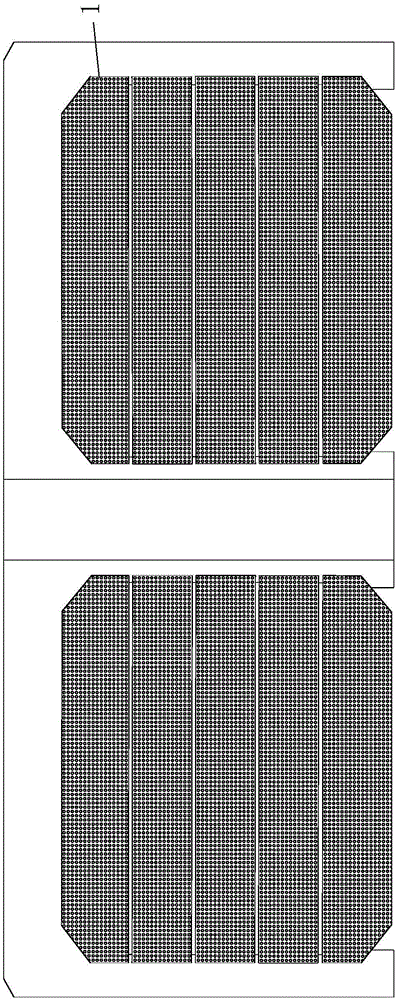

[0023] Please refer to Figure 1-2 , the manufacturing method of the portable solar concentrating device is to use a laminator first, and in a high-temperature environment of 100 ° C, the large-span tensile film 1, solar cells 2, and hot-melt adhesive 3 are sequentially laid from top to bottom. , hardness support plate 4, hot melt adhesive 5, and high temperature waterproof and anticorrosive cloth 6 are combined to form a solar panel; then the solar panel is cooled for 30 minutes to solidify the hot melt adhesive 3 and 5; finally, the large-span stretching film 1 The upper and lower surfaces of the upper and lower surfaces of the paving are provided with dot-shaped raised metal convex nets 7. Under a high temperature environment of 150 ° C, the metal convex nets 7 are laminated with vacuum negative pressure for 30 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com