Automatic vegetable bundling machine

A bundling machine and automatic technology, which is applied in the direction of packaging fruits/vegetables, parts of bundling machinery, and bundling objects, etc., can solve the problems of complex mechanical structure, low degree of automation, and large power consumption, and achieve simple machine structure, machine Effects of small scale and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

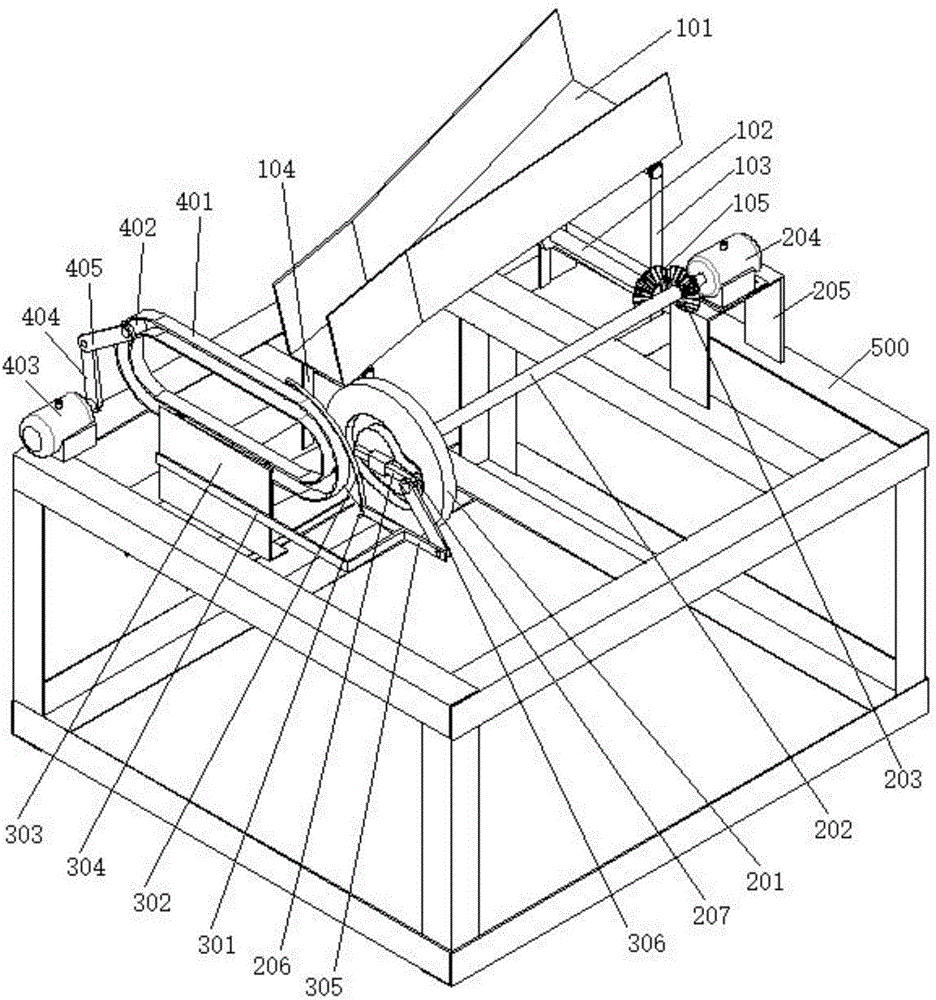

[0030] The invention provides an automatic vegetable binding machine, specifically as Figure 1 to Figure 3 As shown, including the frame 500 and the baler body, the frame 500 in this embodiment is a cuboid structure formed by tailor-welding of 12 equilateral angle steels of 35mm.

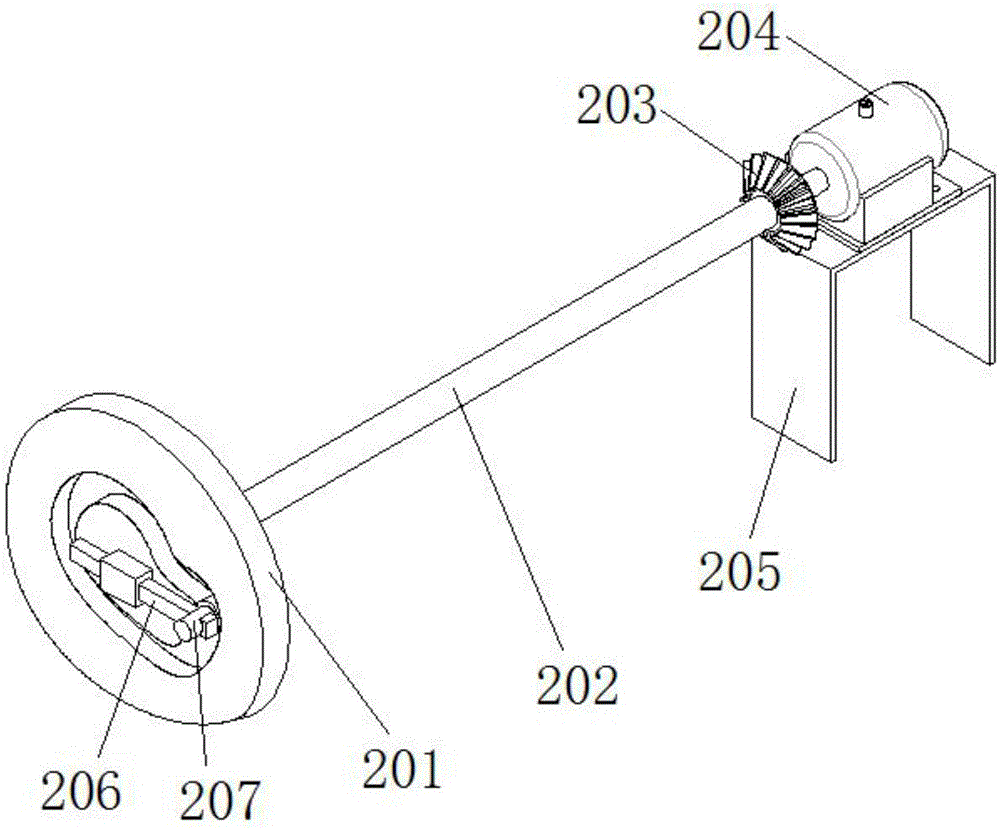

[0031] The strapping machine body is arranged on the frame 500, and the strapping machine body includes a vibration transmission device, a transmission device, a pushing device and a bundling device, and the bundling device is arranged in front of the vibration transmission device.

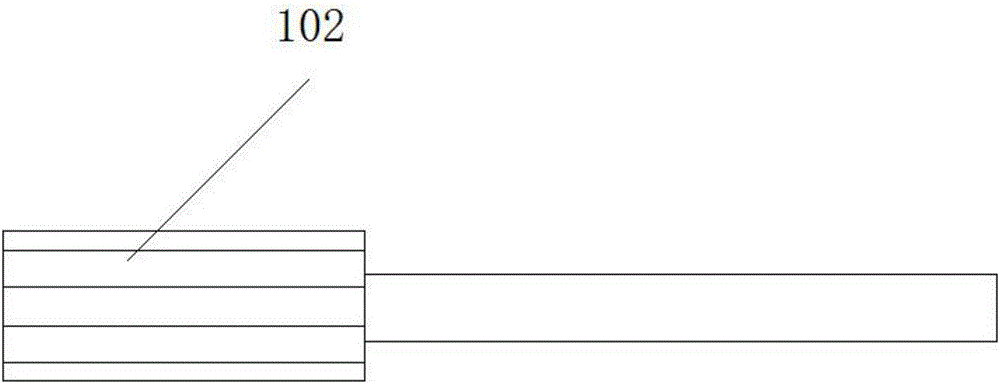

[0032] Vibration transmission device comprises vegetable channel 101, vibrating shaft 102, first support frame 103, second support frame 104 and first bevel gear 105, the height of second support frame 104 is less than the height of first support frame 103, puts vegetable channel One end of 101 is the vegetable inlet, and the other end of the vegetable channel 101 is the vegetable outlet. The width of the vegetable inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com