Plastic wine barrel

A wine barrel and plastic technology, which is applied in the direction of unloading device, sealing member with unloading device, closing, etc., can solve the problems of difficult to achieve rapid assembly, deterioration of wine quality, and difficulty in ensuring tightness, so as to prevent gas from entering the flexible The inside of the bag, the simple assembly process, the effect of enhanced sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

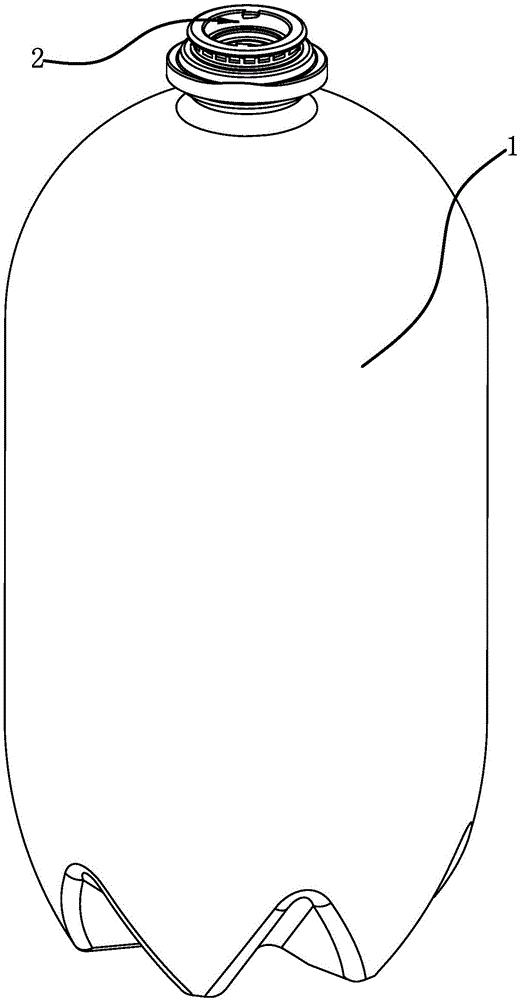

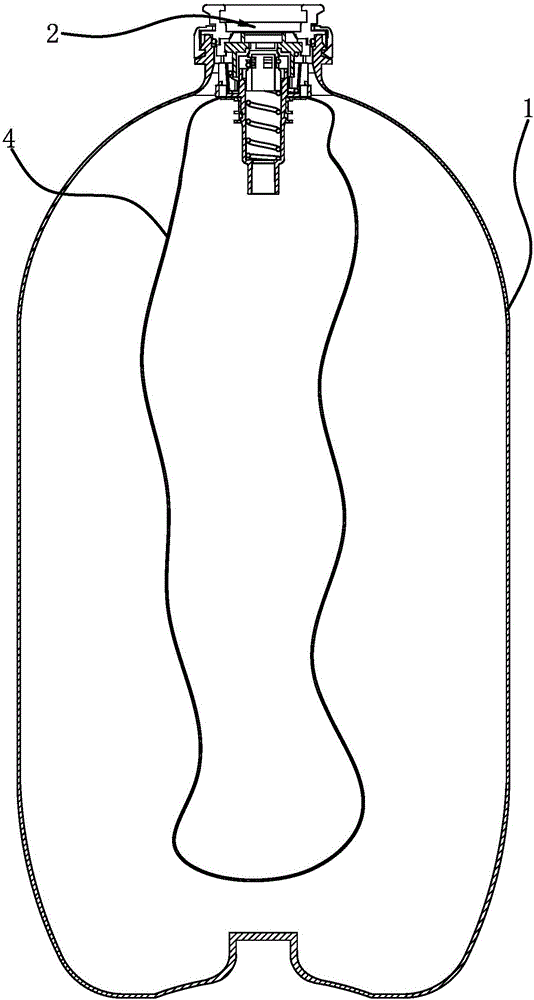

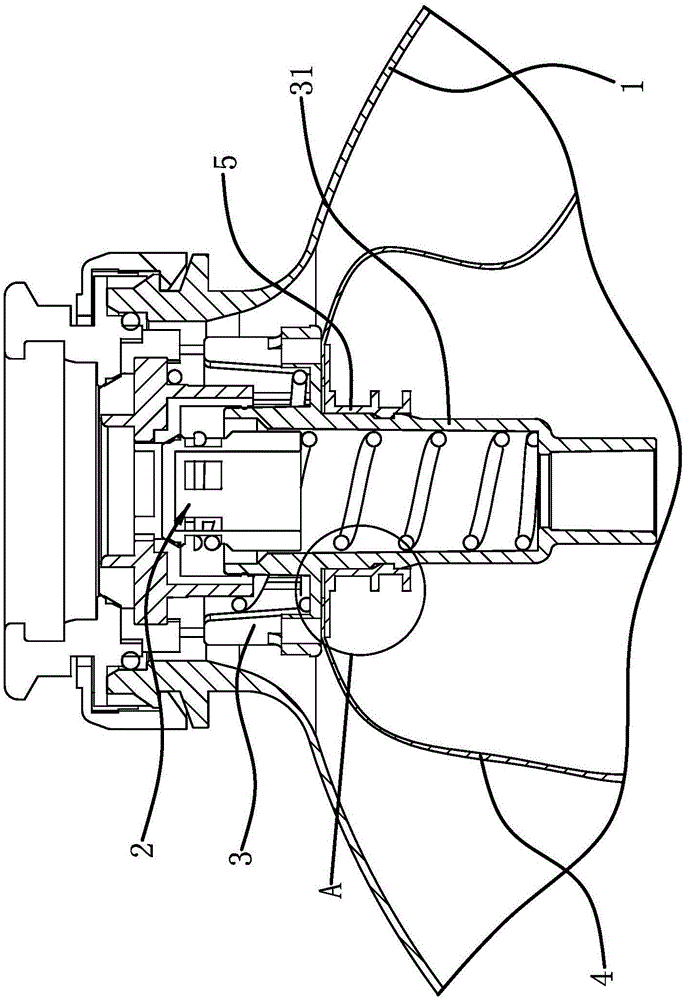

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a plastic wine barrel includes a barrel body 1, a wine spear 2 and a flexible bag 4. The barrel body 1 is made of plastic material and has low cost. The wine spear 2 is fixedly connected to the port of the barrel body 1 and has a bottom frame 3. The frame 3 is a hollow structure, and its internal cavity runs through the upper and lower ends of the bottom frame 3. The flexible bag 4 is made of aluminum foil material, located inside the barrel body 1 and used to hold wine. The wine barrel also includes a sleeve-shaped joint 5. The lower end surface of the chassis 3 has a mounting portion 31. The mounting portion 31 is tubular and faces the inside of the barrel body 1. The joint 5 is fixedly sleeved on the mounting portion 31, and the joint 5 It is airtightly connected with the bottom frame 3, and the outer peripheral wall of the joint 5 has an annular connecting flange 51 in the upp...

Embodiment 2

[0043] The structure of the wine barrel is basically the same as that of Embodiment 1, the difference is that Figure 11 As shown, the bottom frame 3 is made of hard plastic, the outer peripheral wall of the installation part 31 is provided with a sealing groove 311 in the circumferential direction, and the sealing ring 6 is set inside the sealing groove 311, and the inner peripheral wall of the joint 5 is pressed against the sealing ring 6 In general, the structure is sealed by the sealing ring 6, and the structure is relatively simple, and the sealing ring 6 is also a part that is easier to purchase, which makes the processing easier and the cost is lower.

Embodiment 3

[0045] The structure of the wine barrel is basically the same as that of Embodiment 1, the difference is that Figure 12 As shown, the lower end surface of the clamping portion 53 is an inclined plane, the slope faces the center line and slopes downward, the shape of the clamping groove 32 is adapted to the shape of the clamping portion 53 , and the clamping portion 53 is clamped in the clamping groove 32 Inside, the acute-angled edge of the lower end of the engaging part 53 is embedded between the lower groove wall and the bottom surface of the engaging groove 32, so that the engaging part 53 can be hooked on the lower groove wall of the engaging groove 32, and the connection stability of the two is higher. Stronger load-bearing capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com