Belt edge tearing preventing switch of belt conveyor

A belt conveyor and side switch technology, which is applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve problems affecting production continuity and safety, affecting belt use effect, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

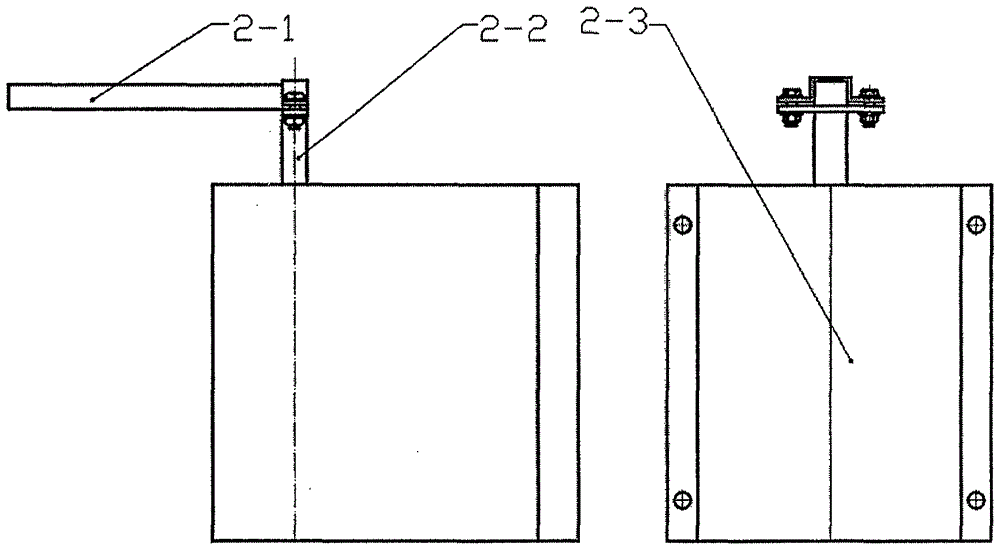

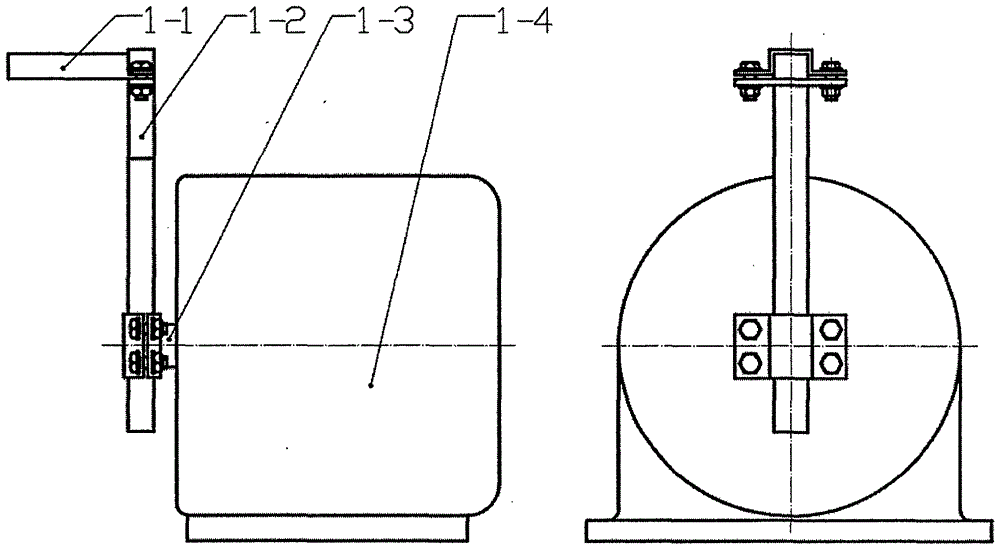

[0015] see figure 1 , the tilt-type belt tear-resistant switch of the belt tear-proof switch provided by the embodiment of the present invention includes: a touch lever 1-1, a tilt lever 1-2, a rotating shaft 1-3, and a switch box with a base 1 -4. Wherein, the touch lever 1-1 is bolted to the tipping bar 1-2 through the U-shaped pressing plate, and the tipping bar 1-2 is bolted to the rotating shaft 1-3 through the U-shaped pressing plate. In this way, the lateral position of the touch bar 1-1 can be adjusted, and the height position of the tipping bar 1-2 can be adjusted. The two can also be directly welded into one body to make a telescopic structure like an open line, and adjust the height and horizontal position to ensure that the switch is within the effective range of the detection distance. The tipping bar 1-2 and the rotating shaft 1-3 can be connected with bolts through the U-shaped pressure plate, so that the height can be adjusted, and the lower end of the tippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com