Automatic discharge device for powder in ton packaging bags and discharge method

An automatic unloading device, a technology for bagging powder, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of non-reusable packaging bags, low labor productivity, dust escape, etc. Enterprise economic benefits and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

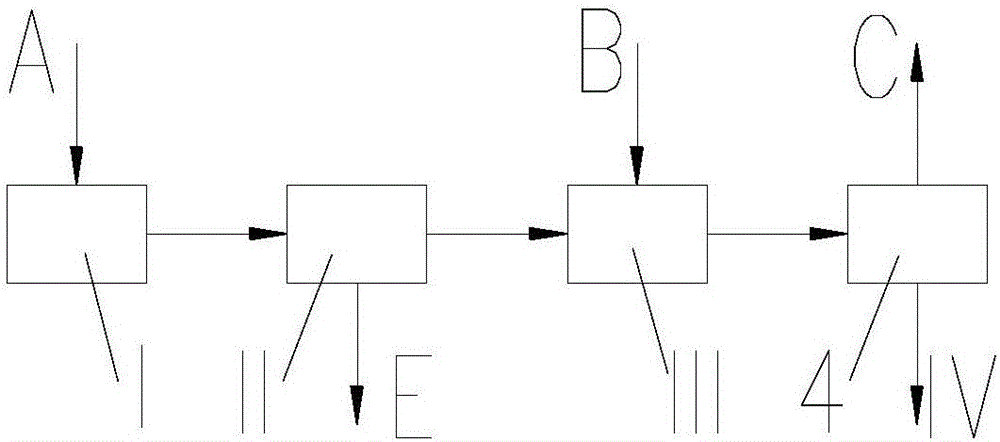

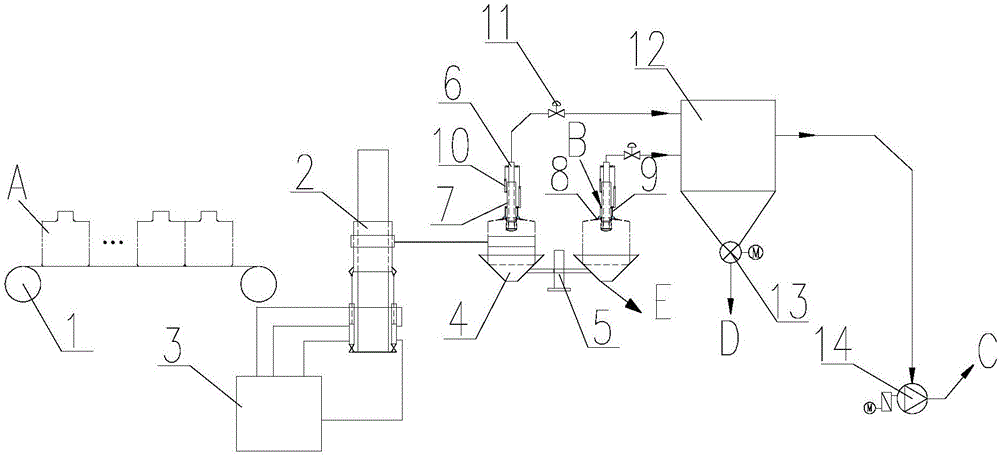

[0065] An automatic unloading device for powder in tons of bags, including the following units: Automatic unloading device for powder in tons of bags, including the following units: preparation unit I, receiving unit II, suction unit III, and unloading unit IV and control unit;

[0066] The preparation unit 1 mainly includes a conveyor 1, a rotating arm mechanism 2 and a hydraulic station 3; one end of the conveyor 1 is provided with a rotating arm mechanism 2, and the rotating arm mechanism 2 is connected to the hydraulic station 3 with a connector;

[0067] The receiving unit II mainly includes a rotating hopper 4 and a central fixed rotating mechanism 5, and the components are connected by connecting pieces;

[0068] The suction unit III mainly includes a suction head 6, a telescopic sleeve 7, a propping device 8, a pocket clamp 9 and a push rod 10, the suction head 6 is slidably connected with the telescopic sleeve 7, and the propping device 8 and the pocket clamp 9 are si...

Embodiment 2

[0088] Adopt the device described in embodiment 1;

[0089] The difference is,

[0090] In the preparation unit, the rotation angle of the rotating arm mechanism α=0~180°;

[0091] In the suction unit, the double-sided electric push rod is a single-side hydraulic push rod;

[0092] In the unloading unit, the air volume of the vacuum pump is 60m 3 / min, pressure -78.4kPa.

[0093] According to the calculation, the specification of the ton bag of alumina is 1.0t / bag, and this device is used to unload 80 bags in one hour, and the unloading capacity is 80t / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com