Hydraulic lifting device

A technology of hydraulic lifting and supporting devices, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of affecting work efficiency, increasing labor costs, wasting manpower, etc., and achieve the effect of saving manpower, reducing operating costs and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

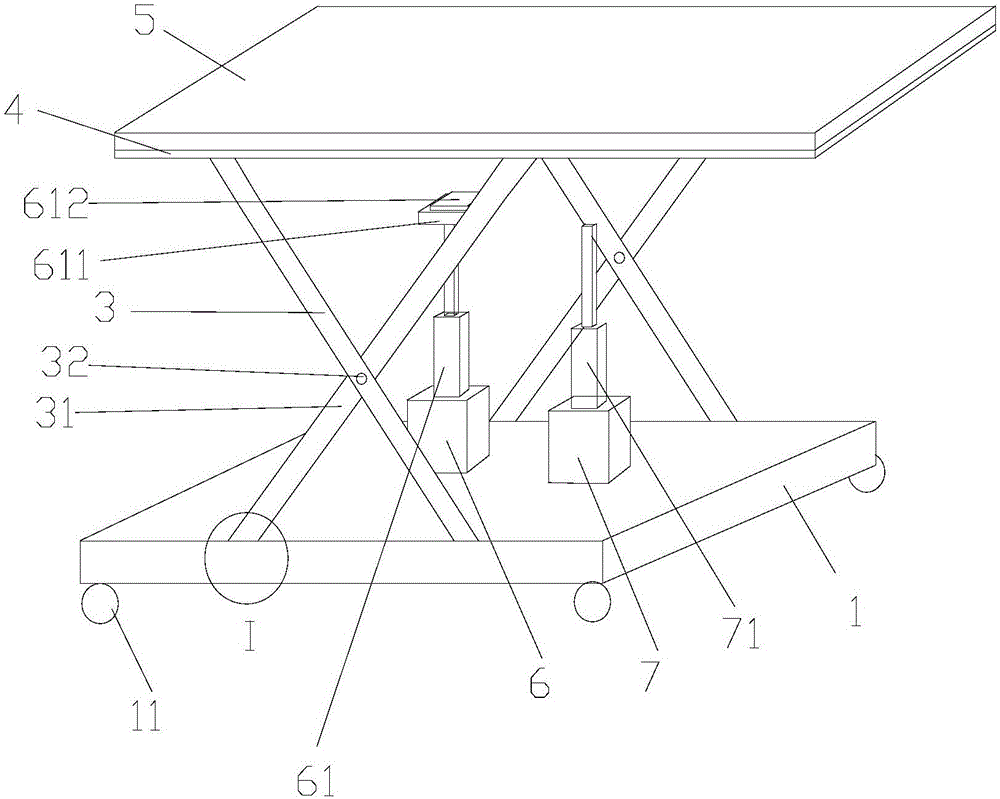

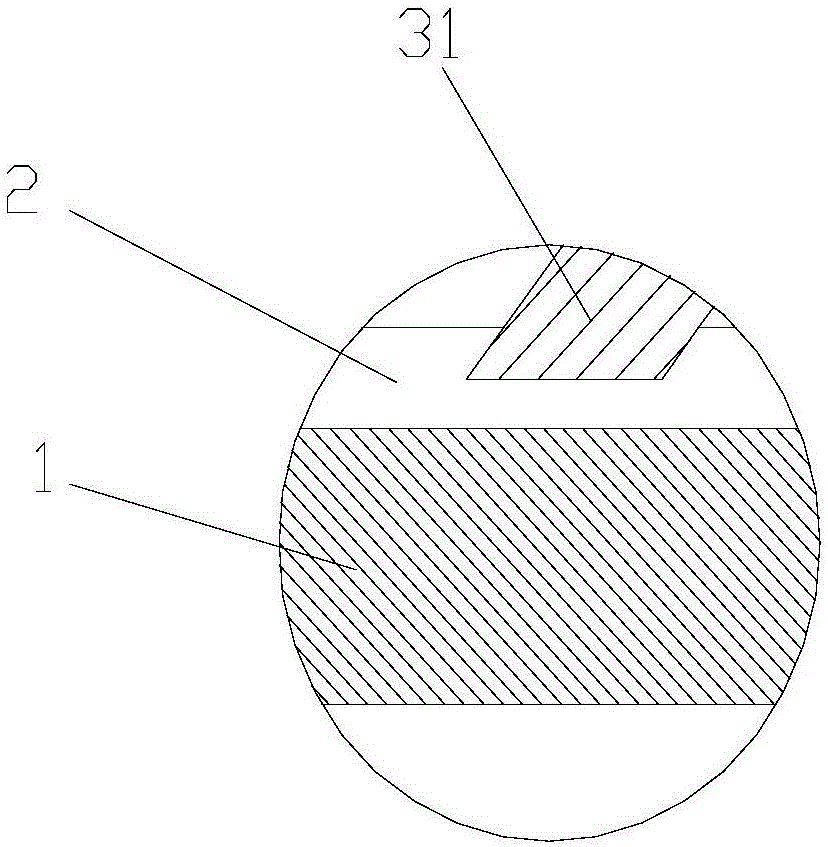

[0016] Such as figure 1 , figure 2 As shown, a hydraulic lifting device includes a base 1. Two parallel chutes 2 are arranged on the base 1. Two support devices 3 are arranged on the chute 2. A support frame 4 is provided on the support device 3. The support frame 4 is provided with a supporting plate 5, and the support device 3 includes two mutually intersecting struts 31, and bolts 32 are arranged at the intersections, and every two struts 31 slide on each chute 2 respectively, and a support device 3 is provided between An air pump 6 is provided, and a pressure rod 61 is arranged on the air pump 6 , and the top end of the pressure rod 61 is connected to the supporting plate 5 .

[0017] In order to facilitate the movement or positioning of the device, universal wheels 11 are provided at the bottom of the base 1 .

[0018] In order to meet the needs of the parts to be conveyed, the pallet 5 is set as a pull-out pallet, which can be easily replaced when damage occurs to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com