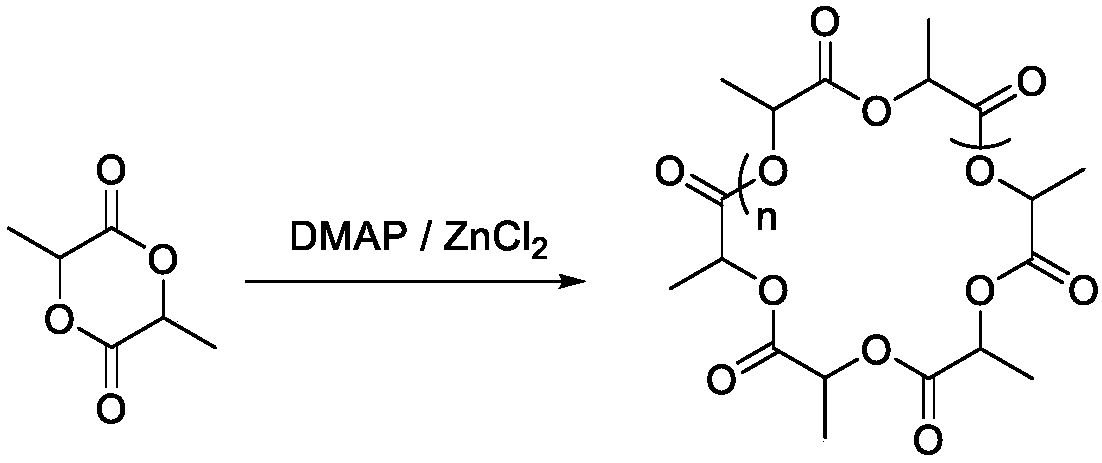

A kind of synthetic method of high molecular weight cyclic polylactic acid

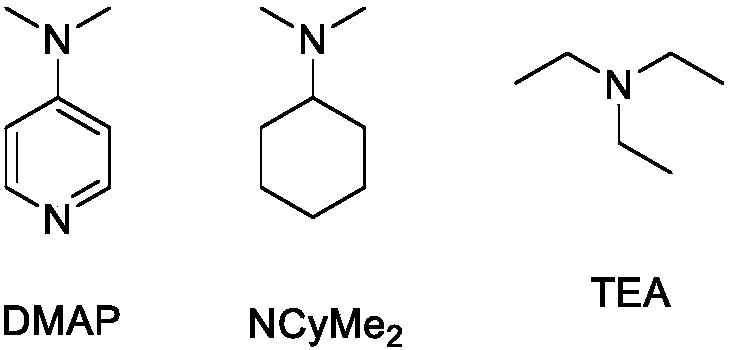

A high-molecular-weight polylactic acid technology, which is applied in the catalytic field of precision synthesis of high-molecular-weight cyclic polylactic acid, can solve the problems of air humidity sensitivity and harsh synthesis conditions, and achieve high molecular weight, simple and easy operation, stable and reliable reaction process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Lactide (2.5mmol, 100equiv.), AlCl 3 (30 μmol, 1.2 equiv.) was added to a polymerization tube with 5 mL THF, and stirred evenly. Then DMAP (25 μmol, 1 equiv.) was added into the reaction system to start the polymerization reaction, the polymerization reaction was carried out at room temperature, and the whole system was under the protection of argon. used during the reaction 1 H NMR detects the lactide content, when the lactide in the body system is completely consumed, add HCl / Et 2 O solution (2 mol / L, 0.05 mmol, 2 equiv.) was used to terminate the reaction. The THF was spun off with a rotary evaporator to obtain the crude product. Use toluene to separate out the complexes and metal salts in the crude product, filter off the solid impurities, and then spin off the toluene. Finally the product was dissolved in CH 2 Cl 2 Then, the mixed liquid was added into the cold methanol solution, and the polymer was precipitated. Centrifuge to obtain a white solid, which is ...

Embodiment 2

[0037] Lactide (0.75mmol, 30equiv.), ZnCl 2 (30 μmol, 1.2 equiv.) was added to a polymerization tube with 2 mL THF, and stirred evenly. Then DMAP (25 μmol, 1 equiv.) was added into the reaction system to start the polymerization reaction, the polymerization reaction was carried out at room temperature, and the whole system was under the protection of argon. used during the reaction 1 H NMR detects the lactide content, when the lactide in the body system is completely consumed, add HCl / Et 2 O solution (2 mol / L, 0.05 mmol, 2 equiv.) was used to terminate the reaction. The THF was spun off with a rotary evaporator to obtain the crude product. Use toluene to separate out the complexes and metal salts in the crude product, filter off the solid impurities, and then spin off the toluene. Finally the product was dissolved in CH 2 Cl 2 Then, the mixed liquid was added into the cold methanol solution, and the polymer was precipitated. Centrifuge to obtain a white solid, which is ...

Embodiment 3

[0039] Lactide (1.75mmol, 70equiv.), FeCl 3 (37.5 μmol, 1.5 equiv.) was added to a polymerization tube with 4 mL THF and stirred evenly. Then DMAP (25 μmol, 1 equiv.) was added into the reaction system to start the polymerization reaction, the polymerization reaction was carried out at room temperature, and the whole system was under the protection of argon. used during the reaction 1 H NMR detects the lactide content, when the lactide in the body system is completely consumed, add HCl / Et 2 O solution (2 mol / L, 0.05 mmol, 2 equiv.) was used to terminate the reaction. The THF was spun off with a rotary evaporator to obtain the crude product. Use toluene to separate out the complexes and metal salts in the crude product, filter off the solid impurities, and then spin off the toluene. Finally the product was dissolved in CH 2 Cl 2Then, the mixed liquid was added into the cold methanol solution, and the polymer was precipitated. Centrifuge to obtain a white solid, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com