Material overlapping and cold precision forging technique for straight toothed spur gear

A technology of spur gear and cold precision forging, which is applied in the direction of wheels, metal processing equipment, transportation and packaging, etc., can solve the problems of difficult forging of spur gears, insufficient filling at corners, and difficult filling of tooth shapes. , to achieve the effect of low deformation resistance, complete tooth profile filling and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments.

[0032] The stacked material cold precision forging forming process of the spur gear comprises the following steps:

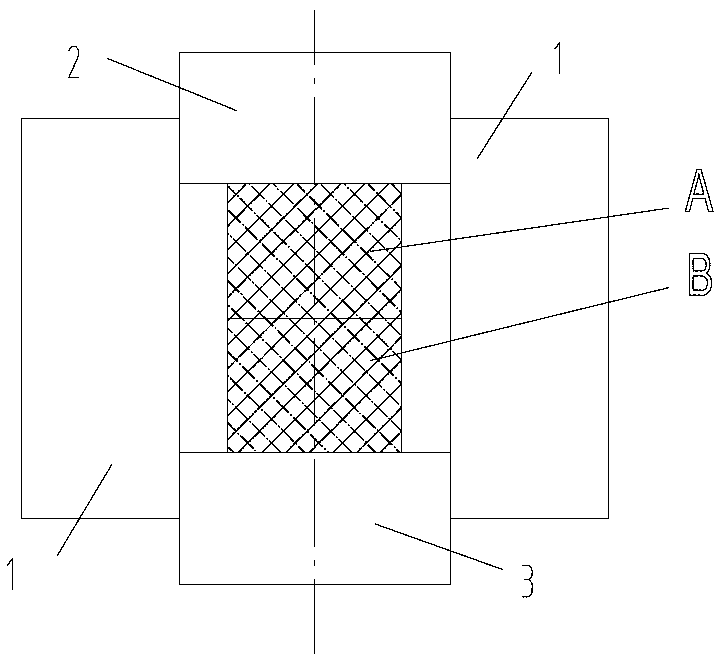

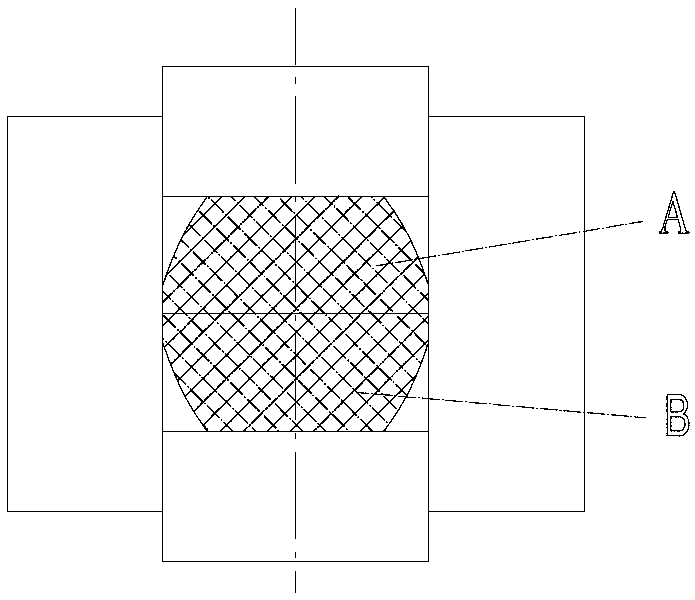

[0033] 1) At room temperature, place two cylindrical blanks with the same volume along their axes in the circular die 1, as Figure 5 shown; and the inner end faces of two cylindrical billets are superimposed, and then the initial extrusion is carried out, such as Image 6 As shown, in the initial stage of the initial extrusion deformation, the stress required to fill the corners is the yield stress of the billet entering the yield stage. At this time, the materials near the end faces of the billets that are in contact with each other will first fit the circular die 1, and the tooth-shaped corners The filling is in good condition;

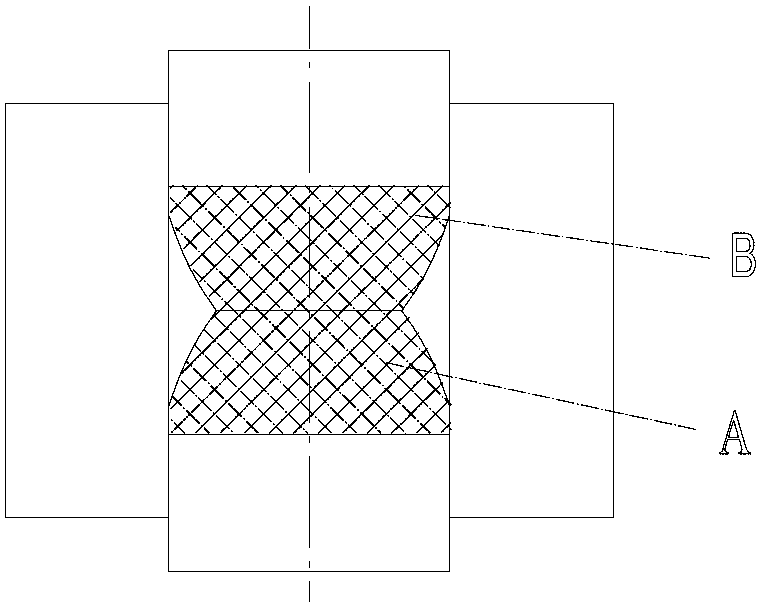

[0034] 2) When the bonding surface between the two cylindrical blanks and the circular die 1 is greater than 1 / 2 of the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com