Polyamide material for preparing cold-resisting heat insulation strip and preparation method of polyamide material

A technology of polyamide and heat insulation strips, which is applied in the field of materials used in the construction industry, can solve problems such as breakage and damage, affect normal use, and poor positioning of heat insulation connection strips, etc., and achieve good low temperature toughness, high mechanical performance, and linear expansion The effect of coefficient stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

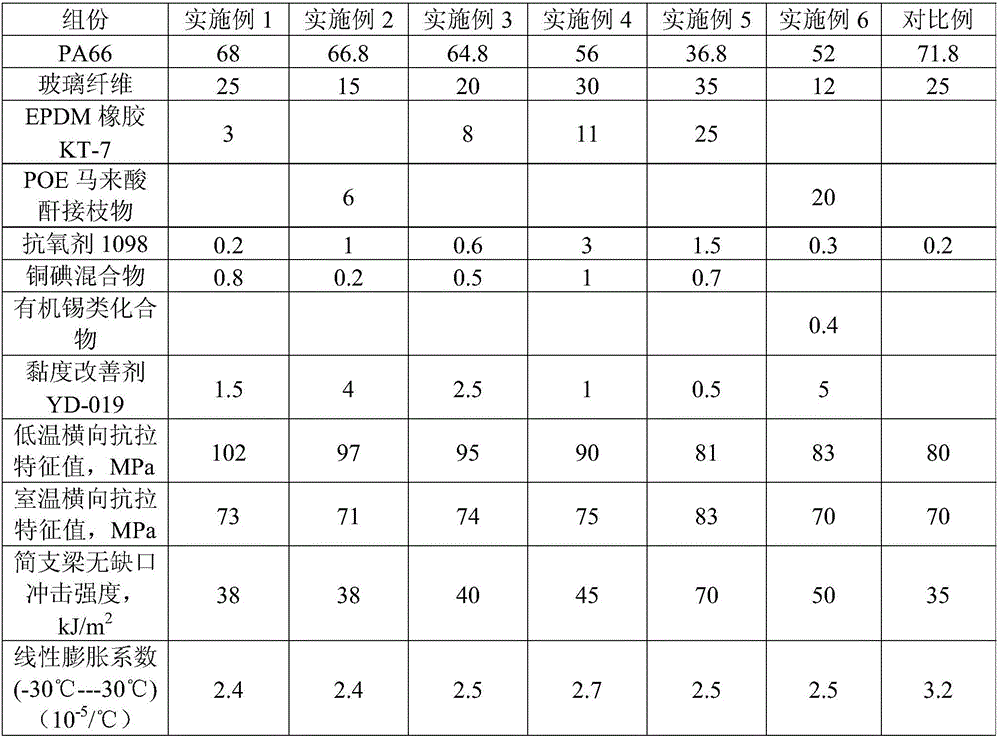

Examples

Embodiment 1

[0031] A polyamide material used to prepare cold-resistant heat insulation strips, made of raw materials including the following weight percentages: PA66 68%; glass fiber 25%; EPDM rubber KT-7 3%; antioxidant 1098 0.2%; copper iodine Mixture 0.8%; viscosity improver YD-019 1.5%.

[0032] The above-mentioned preparation method for preparing the polyamide material of the cold-resistant heat insulation strip comprises the following steps:

[0033] (1) Add PA66, EPDM rubber KT-7, antioxidant 1098, viscosity improver YD-019, and copper-iodine mixture into a high-mixer and mix to obtain a premix;

[0034] (2) adding the premixed material through the main feeding port of the twin-screw extruder, adding glass fiber from the side feeding port of the twin-screw extruder, performing melt extrusion, cooling and granulating, and obtaining a polyamide material;

[0035] Among them, the temperature in the first zone of the twin-screw extruder in step (2) is 210°C-230°C, the temperature in t...

Embodiment 2

[0037] A polyamide material used to prepare cold-resistant heat insulation strips, made of raw materials including the following weight percentages: PA66 66.8%; glass fiber 15%; POE maleic anhydride graft 6%; antioxidant 10981%; copper Iodine mixture 0.2%; viscosity improver YD-019 4%.

[0038] The above-mentioned preparation method for preparing the polyamide material of the cold-resistant heat insulation strip comprises the following steps:

[0039] (1) Add PA66, POE maleic anhydride graft, antioxidant 1098, viscosity improver YD-019, and copper-iodine mixture into a high-mixer and mix to obtain a premix;

[0040] (2) adding the premixed material through the main feeding port of the twin-screw extruder, adding glass fiber from the side feeding port of the twin-screw extruder, performing melt extrusion, cooling and granulating, and obtaining a polyamide material;

[0041] Among them, the temperature in the first zone of the twin-screw extruder in step (2) is 210°C-230°C, the...

Embodiment 3

[0043] A polyamide material used to prepare cold-resistant heat insulation strips, made of raw materials including the following weight percentages: PA66 64.8%; glass fiber 20%; EPDM rubber KT-7 8%; antioxidant 1098 0.6%; copper iodine Mixture 0.5%; viscosity improver YD-019 2.5%.

[0044] The above-mentioned preparation method for preparing the polyamide material of the cold-resistant heat insulation strip comprises the following steps:

[0045] (1) Add PA66, EPDM rubber KT-7, antioxidant 1098, viscosity improver YD-019, and copper-iodine mixture into a high-mixer and mix to obtain a premix;

[0046] (2) adding the premixed material through the main feeding port of the twin-screw extruder, adding glass fiber from the side feeding port of the twin-screw extruder, performing melt extrusion, cooling and granulating, and obtaining a polyamide material;

[0047] Among them, the temperature in the first zone of the twin-screw extruder in step (2) is 210°C-230°C, the temperature in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com