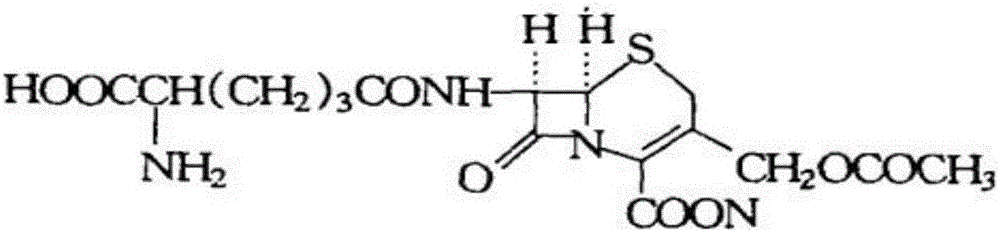

Method for fermentation production of cephalosporin C

A fermentation method and cephalosporin technology, which are applied in the field of fermentation to produce cephalosporin C, can solve the problems of low cephalosporin C production, achieve good industrial application prospects, increase single batch production, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 The method for fermentation production of cephalosporin C of the present invention

[0037] 1. Fermentation method

[0038] (1) Preparation of primary seeds

[0039] Take the slant surface of the eggplant bottle of Cephalosporium acremonium with the deposit number ATCC36225, and prepare a bacterial suspension of 25% (mg / mL). According to the inoculum of 1%, it was inoculated into the seed medium, and cultured at pH 7.0 and 27°C for 50h.

[0040] First-class seed medium: corn steep liquor 20g, soybean oil 35mL, glucose 13g, sucrose 10g, antifoaming agent 0.5g, calcium carbonate 1g.

[0041] (2) Preparation of secondary seeds

[0042] The first-class seeds were inoculated into the second-class seed medium according to 8% of the inoculum, and cultured at pH 6.5 and 27°C for 50h.

[0043] Secondary seed medium: corn steep liquor 16g, soybean oil 40mL, glucose 6g, antifoaming agent 0.5g, calcium carbonate 4g, calcium sulfate 5g, peanut flour 4g, soybean flou...

Embodiment 2

[0066] Embodiment 2 The method for producing cephalosporin C by fermentation of the present invention

[0067] 1. Fermentation method

[0068] (1) Preparation of primary seeds

[0069] Take the slant of the eggplant bottle of Cephalosporium acremonium with preservation number ATCC36225, prepare 25% (mg / mL) bacterial suspension, inoculate it into the seed medium according to the inoculation amount of 1%, and cultivate at pH 7.0 and 27°C for 50h.

[0070] First-class seed medium: corn steep liquor 20g, soybean oil 35mL, glucose 13g, sucrose 10g, antifoaming agent 0.5g, calcium carbonate 1g.

[0071] (2) Preparation of secondary seeds

[0072] The first-class seeds were inoculated into the second-class seed medium according to 8% of the inoculum, and cultured at pH 6.5 and 27°C for 50h.

[0073] Secondary seed medium: corn steep liquor 16g, soybean oil 40mL, glucose 6g, antifoaming agent 0.5g, calcium carbonate 4g, calcium sulfate 5g, peanut flour 4g, soybean flour 4g.

[007...

Embodiment 3

[0091] Embodiment 3 The method for producing cephalosporin C by fermentation of the present invention

[0092] 1. Fermentation method

[0093] (1) Preparation of primary seeds

[0094] Take the slant of the eggplant bottle of Cephalosporium acremonium with preservation number ATCC36225, prepare the bacterial suspension 25% (mg / mL), inoculate it into the seed medium according to the inoculation amount of 1%, and cultivate at pH 7.0 and 27 ℃ for 50h.

[0095] First-class seed medium: corn steep liquor 20g, soybean oil 35mL, glucose 13g, sucrose 10g, antifoaming agent 0.5g, calcium carbonate 1g.

[0096] (2) Preparation of secondary seeds

[0097] The first-class seeds were inoculated into the second-class seed medium according to 8% of the inoculum, and cultured at pH 6.5 and 27°C for 50h.

[0098] Secondary seed medium: corn steep liquor 16g, soybean oil 40mL, glucose 6g, antifoaming agent 0.5g, calcium carbonate 4g, calcium sulfate 5g, peanut flour 4g, soybean flour 4g.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com