A valve sealing surface hardening processing equipment

A technology for processing equipment and valve sealing, which is applied in the field of rolling equipment, can solve the problems of low hardness of the substrate, and achieve the effects of improving the hardness of the sealing surface, improving stability, and facilitating research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

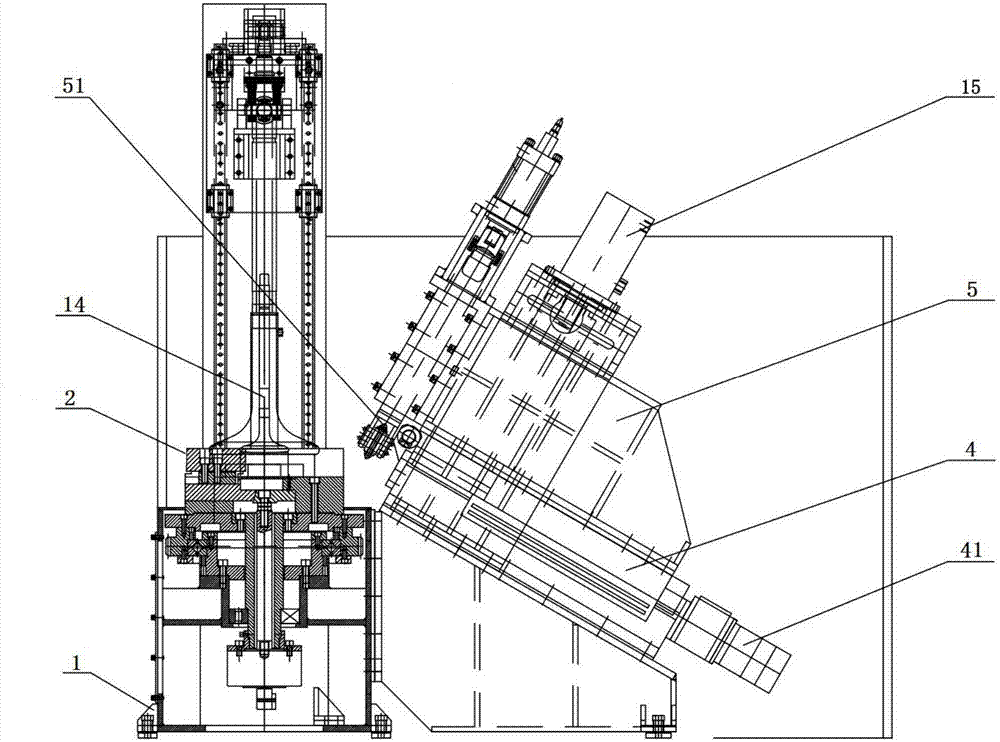

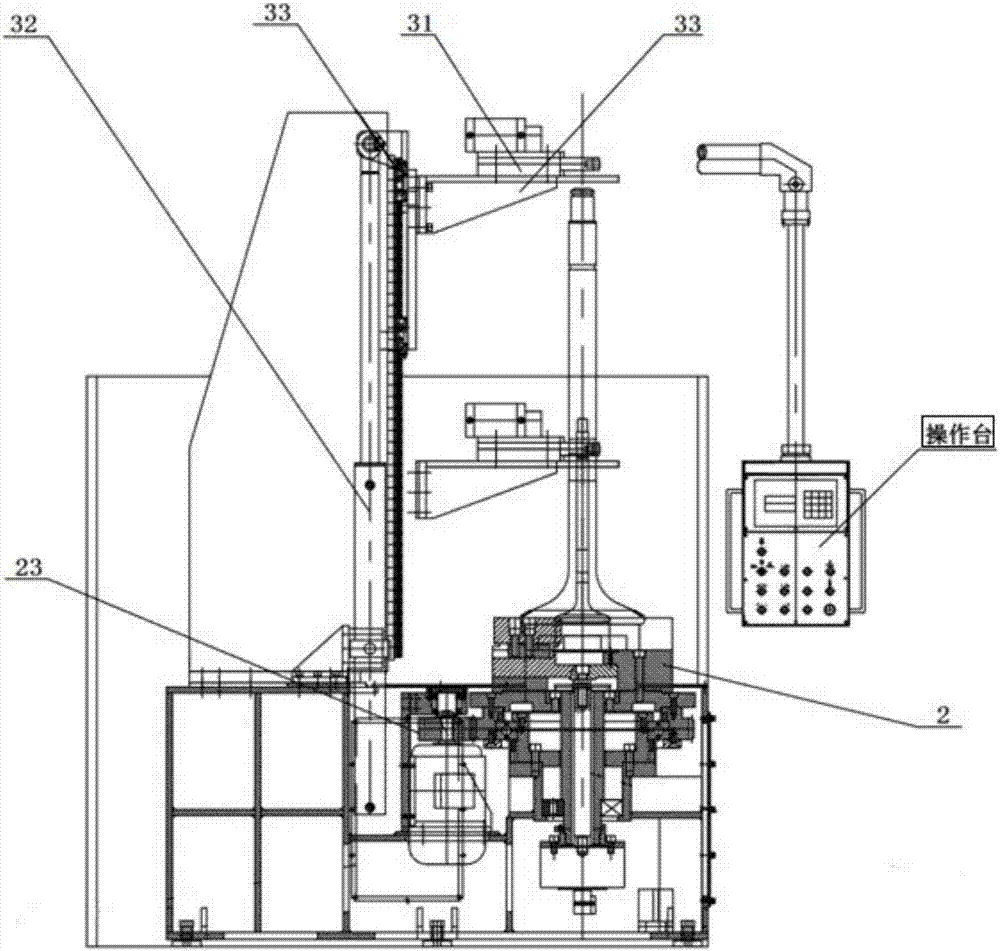

[0026] This embodiment provides a valve sealing surface hardening processing equipment, the structure is as follows Figure 1 to Figure 7 Shown: including frame 1, power turntable 2, vertical moving table 3, sliding table 4, rolling head part 5, compression cylinder 6, hydraulic pump station, electrical control system and isolation protection device.

[0027] Among them, the frame is an L-shaped welded structural member whose structural strength can bear the maximum load when the equipment is working.

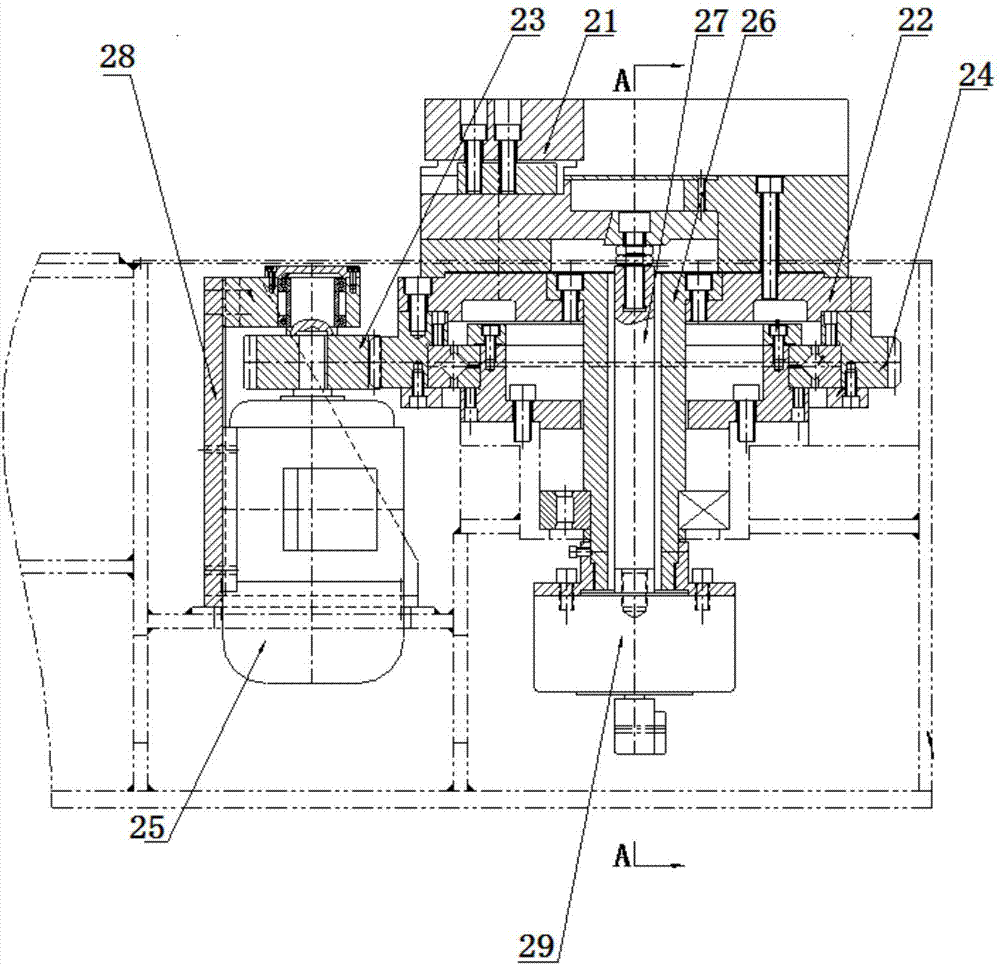

[0028] And in the inside of the frame, a power turntable is fixed, which includes a clamp 21, a power chuck seat 22, a driving gear 23, a driven gear 24, a permanent magnet synchronous motor 25, a rotating power shaft 26, a rotary oil cylinder pull rod 27, and an anti-rotation bracket. 28 and power rotary oil cylinder 29. Wherein, the upper part of the power chuck seat is equipped with a fixture through the connecting piece. The fixture selected in this embodiment is a three-j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com