Dual-layer dual-spiral cooling hot blast valve plate and work method thereof

A double helix, hot blast valve technology, applied in blast furnace parts, furnaces, heating furnaces, etc., can solve the problems of large heat loss, fatigue cracking of welding joints, etc., achieve small heat loss, overcome large cooling water consumption, and reduce heat The effect of passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

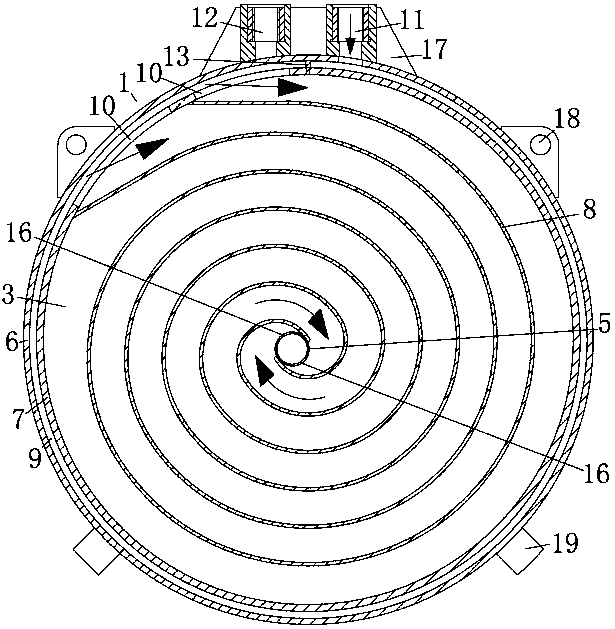

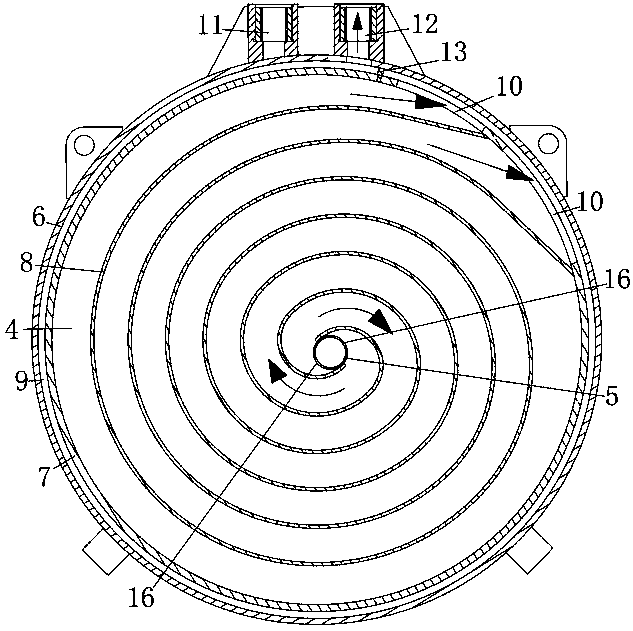

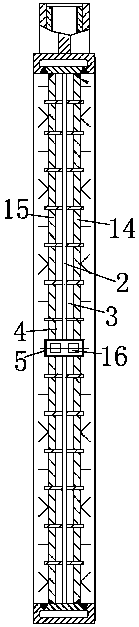

[0017] Such as Figure 1~3 As shown, a double-layer double-helix cooling hot air valve valve plate includes a valve plate body 1, and the interior of the valve plate body is separated by an interlayer plate 2 to separate the adjacent upper water channel 3 and the lower water channel 4, between the upper water channel and the lower water channel Connected through the connecting shaft 5, the upper water channel and the lower water channel include the outer water ring 6, the inner wall plate 7, the double-helix cooling water channel 8, and the connecting shaft from the outside to the inside. Outer ring water channels 9 are formed between them, the outer ring water channels of the same layer are connected with the outer ends of the double-helix cooling water channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com