Vibration and noise reducing structure for driving in highway tunnel and construction method of vibration and noise reducing structure

A vibration and noise reduction, highway tunnel technology, applied in the direction of roads, roads, side ditch/curb stones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

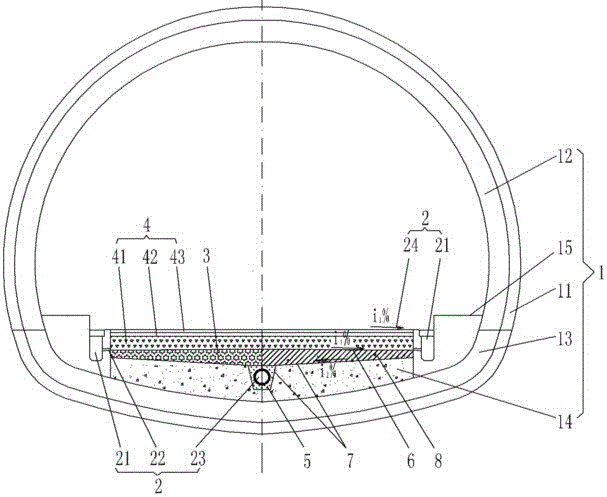

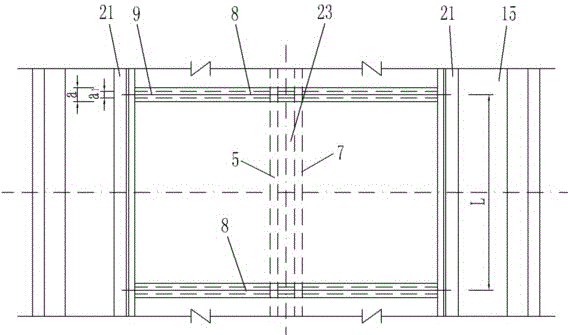

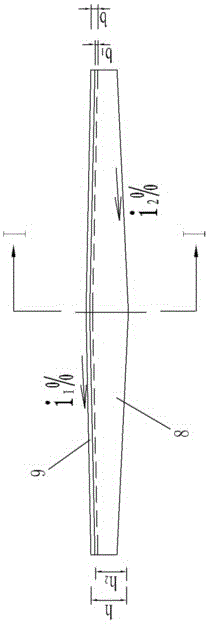

[0062] like Figure 1~Figure 6 As shown, 1. Tunnel structure, 11. Primary support, 12. Secondary lining, 13. Inverted arch, 14. Backfill concrete, 15. Sidewalk, 2. Drainage system, 21. Longitudinal drainage ditch, 22. Horizontal drainage pipe , 23. Central drainage pipe, 24. Transverse drainage slope of road surface, 3. Graded gravel damping layer, 4. Base layer, 41. Emulsified asphalt stabilized gravel, 42. Asphalt concrete, 43. Rubber asphalt concrete, 5 . Sand seepage layer, 6. Upper asphalt water sealing layer, 7. Lower asphalt water sealing layer, 8. Partition beams, 9. Rubber strips, 10. Vehicle load.

[0063] Highway tunnel driving vibration and noise reduction structure and its construction method, such as figure 1 , figure 2 As shown, it is mainly used for vibration and noise reduction of highway tunnel driving in sensitive areas. The dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com