Underground diaphragm wall construction method used under low-clearance condition

A technique for underground diaphragm walls and construction methods, which can be applied to sheet pile walls, foundation structure engineering, construction, etc., and can solve problems such as the failure of slotting machines and obstacles to the construction of underground diaphragm walls, and achieve mature and reliable construction methods and difficult construction Low, the effect of limited solution conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment The construction site is located in a pre-built subway station. The subway station is a double-column, three-span underground three-storey station. The two overpasses above the station pass through the foundation pit vertically and horizontally. , the clearance above the station is 8.1m.

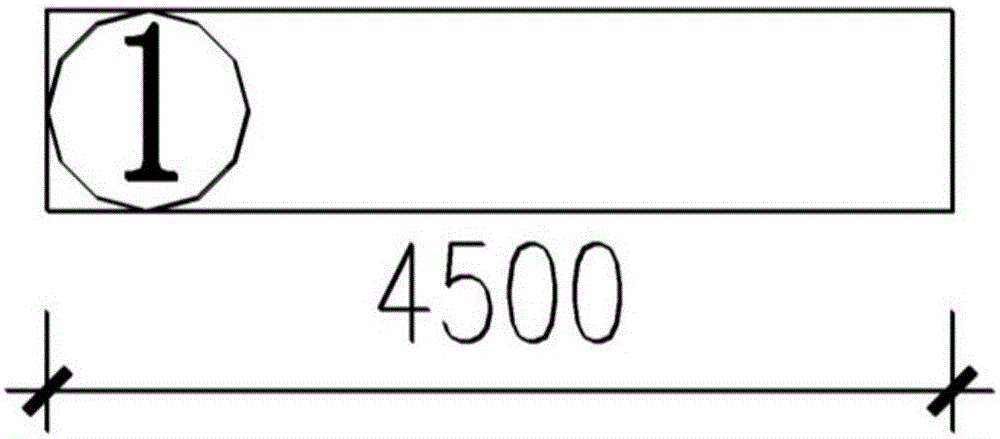

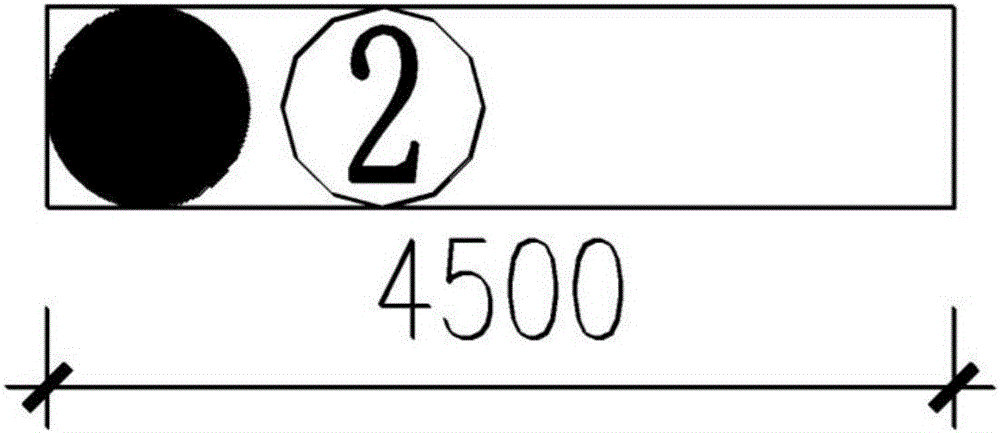

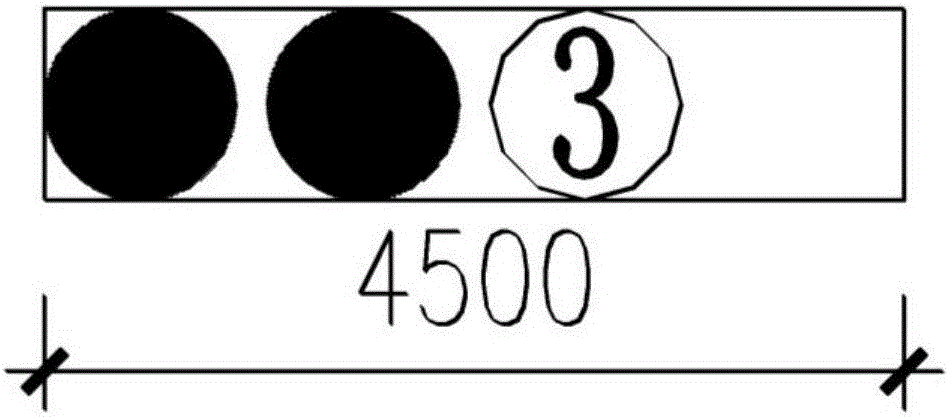

[0018] Firstly adopt the reverse circulation rotary drilling rig to arrange several equal-diameter circular holes on the underground continuous wall, and the circle centers of some equal-diameter circular holes are located on the same horizontal line. Then use a percussion drill and a rectangular hammer to form a rectangular groove. The rectangular groove covers all the circular holes. The diameter of the circular hole is equal to the height of the rectangular groove. It is located at the leftmost end of the leftmost circular hole. The rightmost distance of the rightmost circular hole is equal to the width of the rectangular slot, preferably 4500 mm. The steps are as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com