Process for construction of piled raft in low-buried and unsymmetrical pressure flexible plastic karst tunnel

A construction technology and technology in the tunnel, which can be applied to sheet pile walls, foundation structure engineering, excavation, etc., and can solve problems such as blockage of the karst tunnel base or difficulties in reinforcement construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

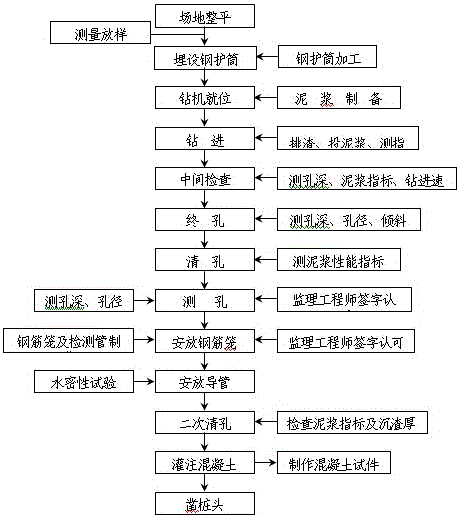

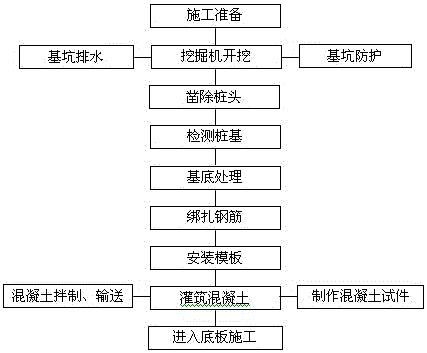

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the invention:

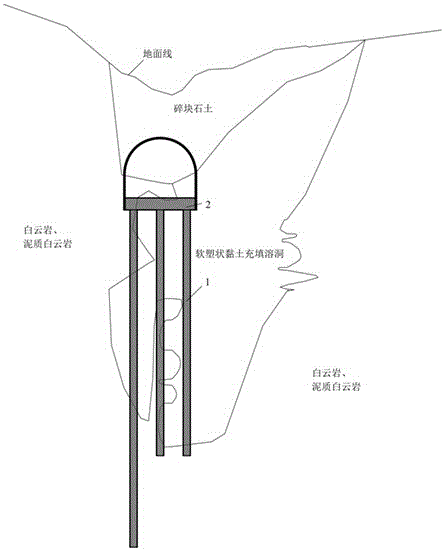

[0017] The pile raft structure of the present invention is composed of a lower cast-in-place pile 1 and an upper raft slab 2, both of which are connected by steel bars; the cast-in-place pile 1 adopts a reinforced concrete bored pile, and the raft slab 2 adopts a C35 corrosion-resistant reinforced concrete raft slab; In the bored cast-in-place pile; the steel cage is processed by the mold forming method; the steel cage is installed by the drilling rig to lift and connect and install. The total length of the raft construction is 75m, the width is 14.5m, and the height is 2.5m. The diameter of the bored piles is 1.5m, the distance between the piles is 4m vertically and 5.5m horizontally, using C35 corrosion-resistant reinforced concrete, and the bottom of the end-bearing piles is embedded in the bedrock to a depth of not less than 2m. Two deformation joints are set in the middle of the plate, and one deformation joint is set at each end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com