C-shaped wooden structure material for construction and preparation method thereof

A wooden structure and construction technology, applied in the direction of building structure, construction, wood processing equipment, etc., can solve the problems of large fossil energy consumption, incompatible with low-carbon economic development, etc., achieve fast construction speed and save the consumption of high-quality wood , Improve the effect of the internal space structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

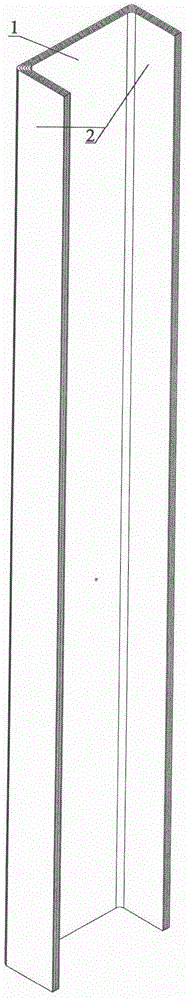

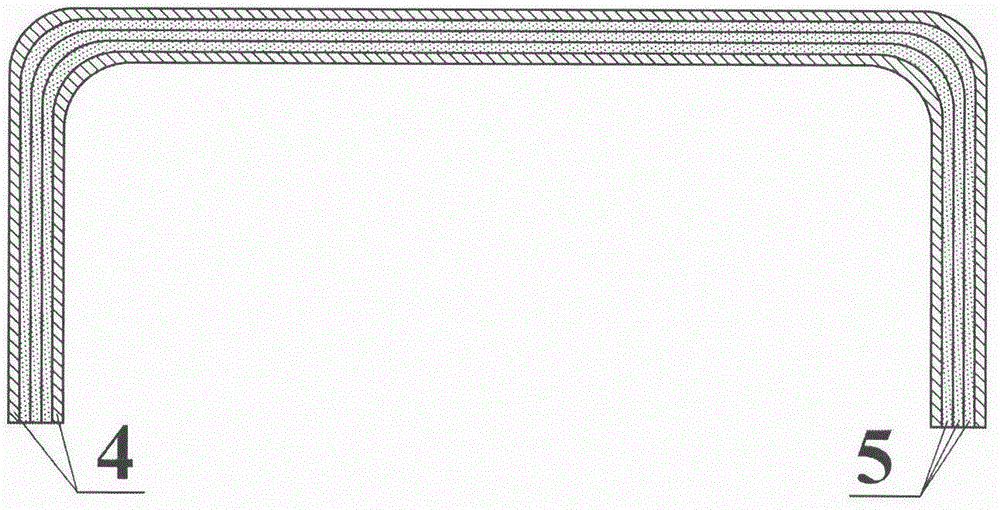

[0028] Example one: such as figure 1 , 3 As shown, a C-type wooden structural material for construction, its structure includes a web 1 and a flange 2. The angle between the web 1 and the flanges 2 on both sides is 90 degrees, and the radius of the arc of the bending part is 10mm; The blank method is five-layer veneer criss-crossing, the surface layer of the horizontally textured wood veneer 4 fiber direction is perpendicular to the long axis direction of the structural material, and the middle three layers of longitudinally textured wood veneer 5 fiber direction is parallel to the structural material long axis direction. The veneer 5 is coated with phenolic resin adhesive on both sides as required.

[0029] A method for processing a C-type wooden structural material for construction in the first embodiment above, which includes the following steps:

[0030] (1) Cut the peeled wooden veneer to remove material defects that do not meet the quality standards of the wooden structure co...

Embodiment 2

[0035] Embodiment two: such as figure 1 , 4 As shown, a C-type wooden structural material for construction, its structure I includes a web 1 and a flange 2. The angle between the web 1 and the flanges 2 on both sides is 90 degrees, and the radius of the arc of the bending part is 10mm; The blank assembly method is a five-layer veneer criss-crossing, veneer 5 is a vertical grain veneer, veneer 6 is a horizontal grain wood veneer coated with phenolic resin adhesive on both sides, and veneer 7 is a surface longitudinal grain veneer.

[0036] A method for processing a C-type wooden structural material for construction in the second embodiment above, which includes the following steps:

[0037] (1) Cut the peeled wooden veneer to remove material defects that do not meet the quality standards of the wooden structure composite material, and use a veneer softening machine to create several small cracks on the tight surface of the veneer, and make it all Probably symmetrical with the pine n...

Embodiment 3

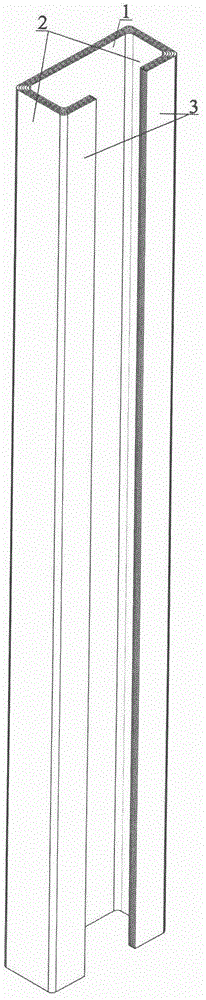

[0042] Embodiment three: such as figure 2 , 5 As shown, a C-type wooden structural material for construction, its structure II includes a web 1, a flange 2 and a curling edge 3. The angle between the web 1 and the flanges 2 on both sides is 90 degrees, and the flange 2 and the curling edge 3 The angle is 90 degrees, the radius of the arc at the bending part is 10mm; the assembly method is five-layer veneer crisscrossing, the surface layer of horizontal grained wood veneer 4 The fiber direction is perpendicular to the long axis direction of the structural material, and the middle three layers are longitudinal The fiber direction of the textured wood veneer 5 is parallel to the long axis direction of the structural material. The veneer 5 is coated with phenolic resin adhesive on both sides as required.

[0043] A method for processing a C-type wooden structural material for construction in the third embodiment above, which includes the following steps:

[0044] (1) Cut the wood ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com